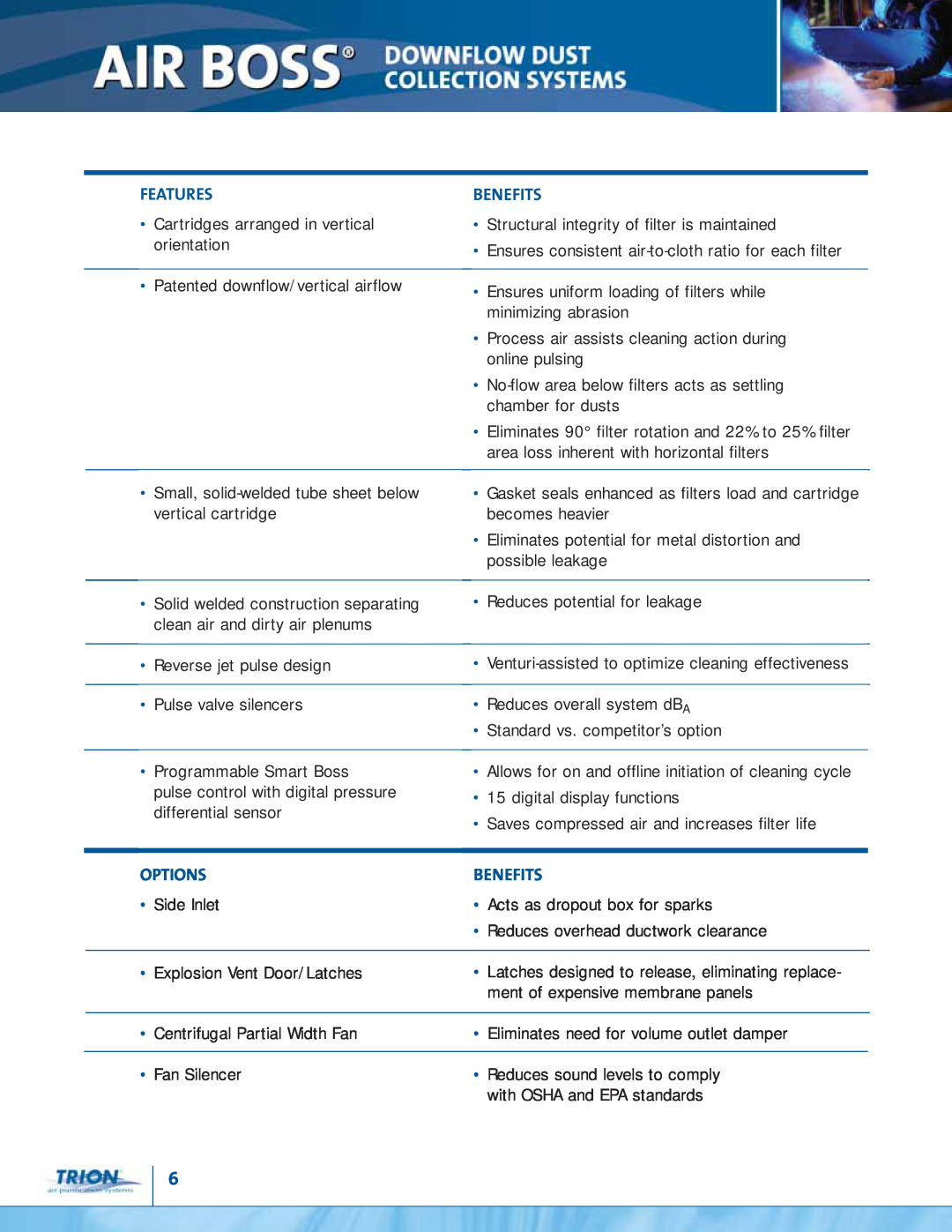

| FEATURES | BENEFITS |

|

| • Cartridges arranged in vertical | • Structural integrity of filter is maintained |

|

| orientation | • Ensures consistent |

|

|

|

| |

|

|

|

|

| • Patented downflow/vertical airflow | • Ensures uniform loading of filters while |

|

|

|

| |

|

| minimizing abrasion |

|

|

| • Process air assists cleaning action during |

|

|

| online pulsing |

|

|

| • |

|

|

| chamber for dusts |

|

|

| • Eliminates 90° filter rotation and 22% to 25% filter |

|

|

| area loss inherent with horizontal filters |

|

|

|

|

|

•Small,

•Gasket seals enhanced as filters load and cartridge becomes heavier

•Eliminates potential for metal distortion and possible leakage

| • Solid welded construction separating | • Reduces potential for leakage | |

| clean air and dirty air plenums |

|

|

|

|

|

|

| • Reverse jet pulse design | • | |

|

|

|

|

| • Pulse valve silencers | • Reduces overall system dBA | |

|

| • Standard vs. competitor’s option | |

|

|

|

|

•Programmable Smart Boss

pulse control with digital pressure differential sensor

•Allows for on and offline initiation of cleaning cycle

•15 digital display functions

•Saves compressed air and increases filter life

| OPTIONS | BENEFITS | |

| • Side Inlet | • Acts as dropout box for sparks | |

|

| • Reduces overhead ductwork clearance | |

|

|

|

|

| • Explosion Vent Door/Latches | • Latches designed to release, eliminating replace- | |

|

| ment of expensive membrane panels | |

|

|

|

|

| • Centrifugal Partial Width Fan | • Eliminates need for volume outlet damper | |

|

|

|

|

| • Fan Silencer | • Reduces sound levels to comply | |

|

| with OSHA and EPA standards | |

6