Application Guide

Match Battery Amp-Hour Capacity to Your Application

Select a battery or system of batteries that will provide your Inverter with proper DC voltage and an adequate

•STEP 1: Determine Total Wattage Required

Add the wattage ratings of all equipment you will connect to your Inverter. Wattage ratings are usually listed in equipment manuals or on nameplates. If your equipment is rated in amps, multiply that number times AC utility voltage to determine watts. (Example: a ¼ in. drill

requires 2½ amps. 2½ amps × 120 volts = 300 watts.)

Note: Your Inverter will operate at higher efficiencies at about 75% - 80% of nameplate rating.

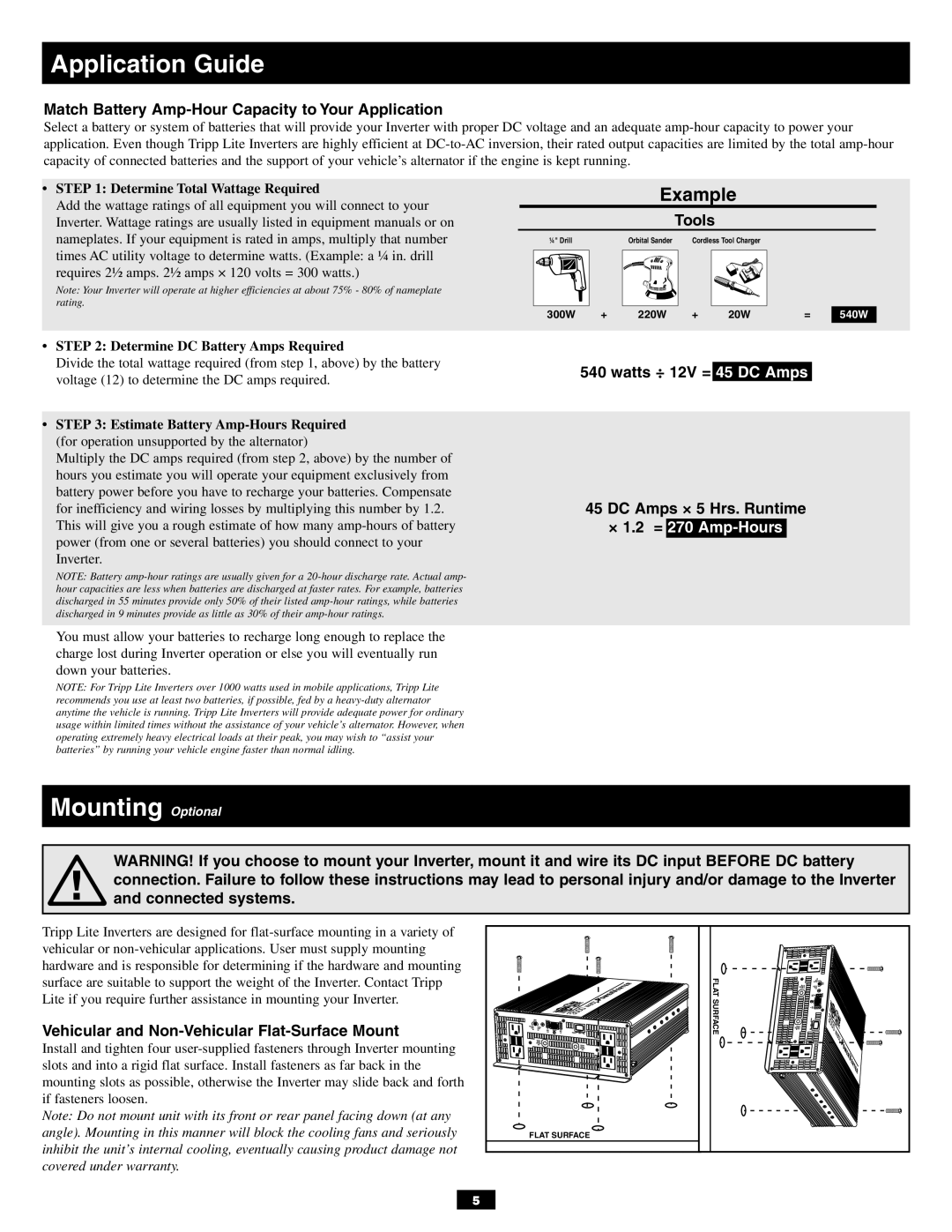

Example

Tools

¼" Drill | Orbital Sander | Cordless Tool Charger |

300W | + | 220W | + | 20W | = | 540W |

• STEP 2: Determine DC Battery Amps Required

Divide the total wattage required (from step 1, above) by the battery |

|

|

|

|

|

540 watts ÷ 12V = | 45 DC Amps |

| |||

voltage (12) to determine the DC amps required. |

| ||||

|

|

|

|

| |

|

|

|

|

|

|

• STEP 3: Estimate Battery |

|

|

|

|

|

(for operation unsupported by the alternator) |

|

|

|

|

|

Multiply the DC amps required (from step 2, above) by the number of |

|

|

|

|

|

hours you estimate you will operate your equipment exclusively from |

|

|

|

|

|

battery power before you have to recharge your batteries. Compensate | 45 DC Amps × 5 Hrs. Runtime | ||||

for inefficiency and wiring losses by multiplying this number by 1.2. | |||||

This will give you a rough estimate of how many | × 1.2 = | 270 |

| ||

power (from one or several batteries) you should connect to your |

|

|

|

|

|

Inverter. |

|

|

|

|

|

NOTE: Battery |

|

|

|

|

|

hour capacities are less when batteries are discharged at faster rates. For example, batteries |

|

|

|

|

|

discharged in 55 minutes provide only 50% of their listed |

|

|

|

|

|

discharged in 9 minutes provide as little as 30% of their |

|

|

|

|

|

|

|

|

|

|

|

You must allow your batteries to recharge long enough to replace the |

|

|

|

|

|

charge lost during Inverter operation or else you will eventually run |

|

|

|

|

|

down your batteries. |

|

|

|

|

|

NOTE: For Tripp Lite Inverters over 1000 watts used in mobile applications, Tripp Lite |

|

|

|

|

|

recommends you use at least two batteries, if possible, fed by a |

|

|

|

|

|

anytime the vehicle is running. Tripp Lite Inverters will provide adequate power for ordinary |

|

|

|

|

|

usage within limited times without the assistance of your vehicle’s alternator. However, when |

|

|

|

|

|

operating extremely heavy electrical loads at their peak, you may wish to “assist your |

|

|

|

|

|

batteries” by running your vehicle engine faster than normal idling. |

|

|

|

|

|

Mounting Optional

WARNING! If you choose to mount your Inverter, mount it and wire its DC input BEFORE DC battery connection. Failure to follow these instructions may lead to personal injury and/or damage to the Inverter and connected systems.

Tripp Lite Inverters are designed for

Vehicular and Non-Vehicular Flat-Surface Mount

Install and tighten four

Note: Do not mount unit with its front or rear panel facing down (at any angle). Mounting in this manner will block the cooling fans and seriously inhibit the unit’s internal cooling, eventually causing product damage not covered under warranty.

FLAT SURFACE |

FLAT SURFACE |

5