2.With the drive control released, there must be 1/8” clearance between the friction wheel and the drive pulley in all positions of the shift lever.

3.With the drive control engaged, the friction wheel must contact the drive pulley. See Figure

4.If adjustment is necessary, loosen the lower hex nut on the drive cable index bracket and pivot the bracket upward or downward as necessary. Refer to Figure

5.Reassemble the frame cover and return the unit back to its operating position.

NOTE: If you placed plastic under the gas cap, be certain to remove it now.

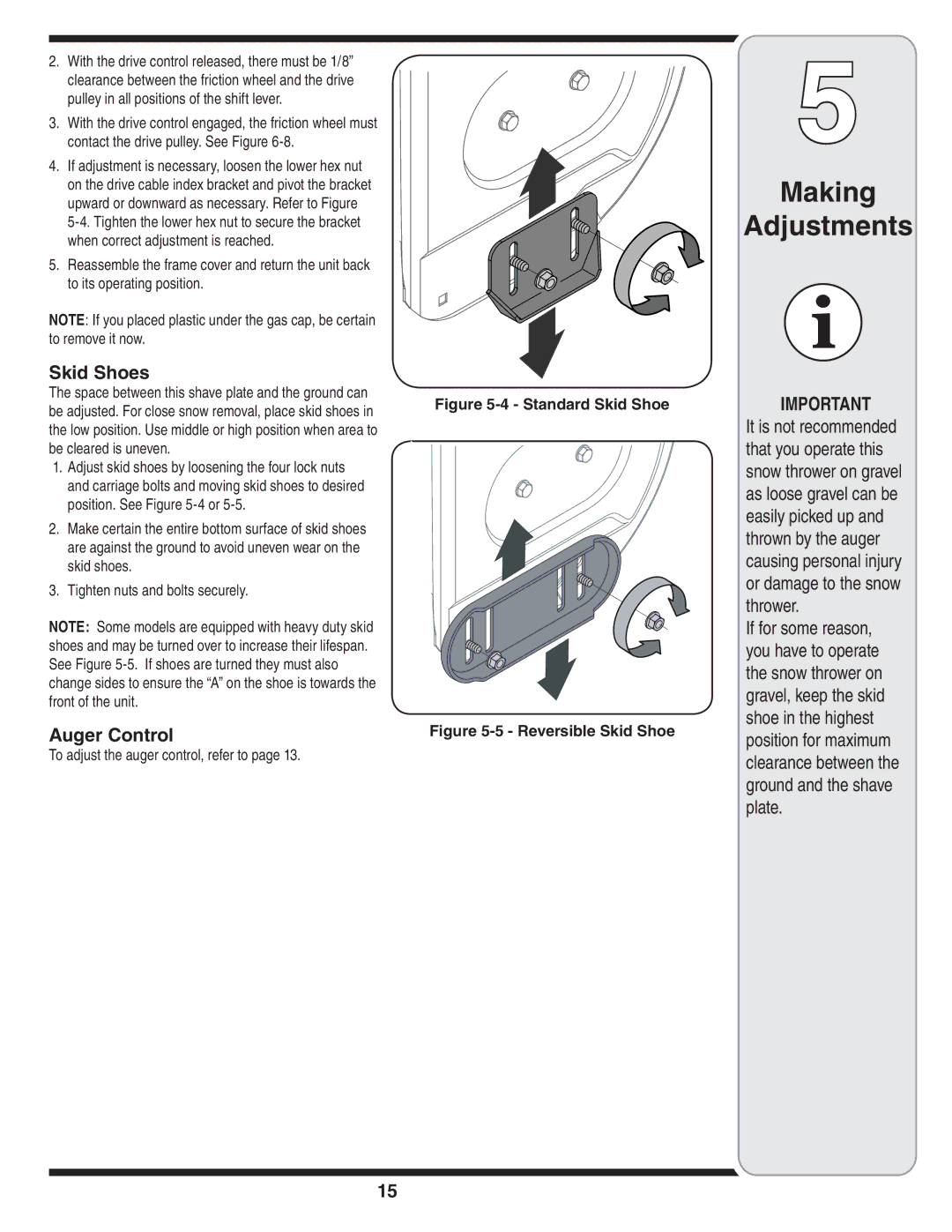

Skid Shoes

The space between this shave plate and the ground can be adjusted. For close snow removal, place skid shoes in the low position. Use middle or high position when area to be cleared is uneven.

1.Adjust skid shoes by loosening the four lock nuts and carriage bolts and moving skid shoes to desired position. See Figure

2.Make certain the entire bottom surface of skid shoes are against the ground to avoid uneven wear on the skid shoes.

3.Tighten nuts and bolts securely.

NOTE: Some models are equipped with heavy duty skid shoes and may be turned over to increase their lifespan. See Figure

Auger Control

To adjust the auger control, refer to page 13.

Figure 5-4 - Standard Skid Shoe

Figure 5-5 - Reversible Skid Shoe

5

Making

Adjustments

IMPORTANT

It is not recommended that you operate this snow thrower on gravel as loose gravel can be easily picked up and thrown by the auger causing personal injury or damage to the snow thrower.

If for some reason, you have to operate the snow thrower on gravel, keep the skid shoe in the highest position for maximum clearance between the ground and the shave plate.

15