•Insert hex bolts through top holes in jack stand mounting brackets and holes in jack stand. Secure with lock washers and hex nuts. See Figure 3.

•Insert hex bolts through upper holes in the bottom of mounting brackets and jack stand. Secure with lock washers and hex nuts. See Figure 3.

Hitch Assembly

The hitch assembly is already attached to the tongue before shipping. If not, follow instructions below:

•Remove the hardware from the hitch assembly and place the hitch on the end of the tongue.

•Insert hex bolt through flat washer, end of safety chain, spacer, and then rear hitch hole. Pivot the end of safety chain so it faces the ball end of hitch. See Figure 4.

|

|

|

| Lock |

|

|

| ||

|

| Nut | ||

Flat |

|

|

|

|

Washer |

|

|

|

|

Hex |

| Hex | ||

Spacer | Bolt | |||

Bolt | Hitch | |||

|

| Assembly | ||

| Chain |

|

|

|

Figure 4

•Insert other spacer, safety chain, and flat washer on the other end of the hex bolt and secure with hex lock nut. See Figure 4.

•Insert hex bolt through the front hole of hitch and secure with flat washer and hex lock nut. Tighten both hex nuts to 23

Attaching Wheels

•Block up the reservoir tank assembly about eight to twelve inches.

•Remove and discard plastic shipping caps on the outside of the wheels.

•Remove the cotter pin, hex slotted nut, and flat washer from each axle.

NOTE: It is recommended that you polish the axles with emery cloth before you install the wheels.

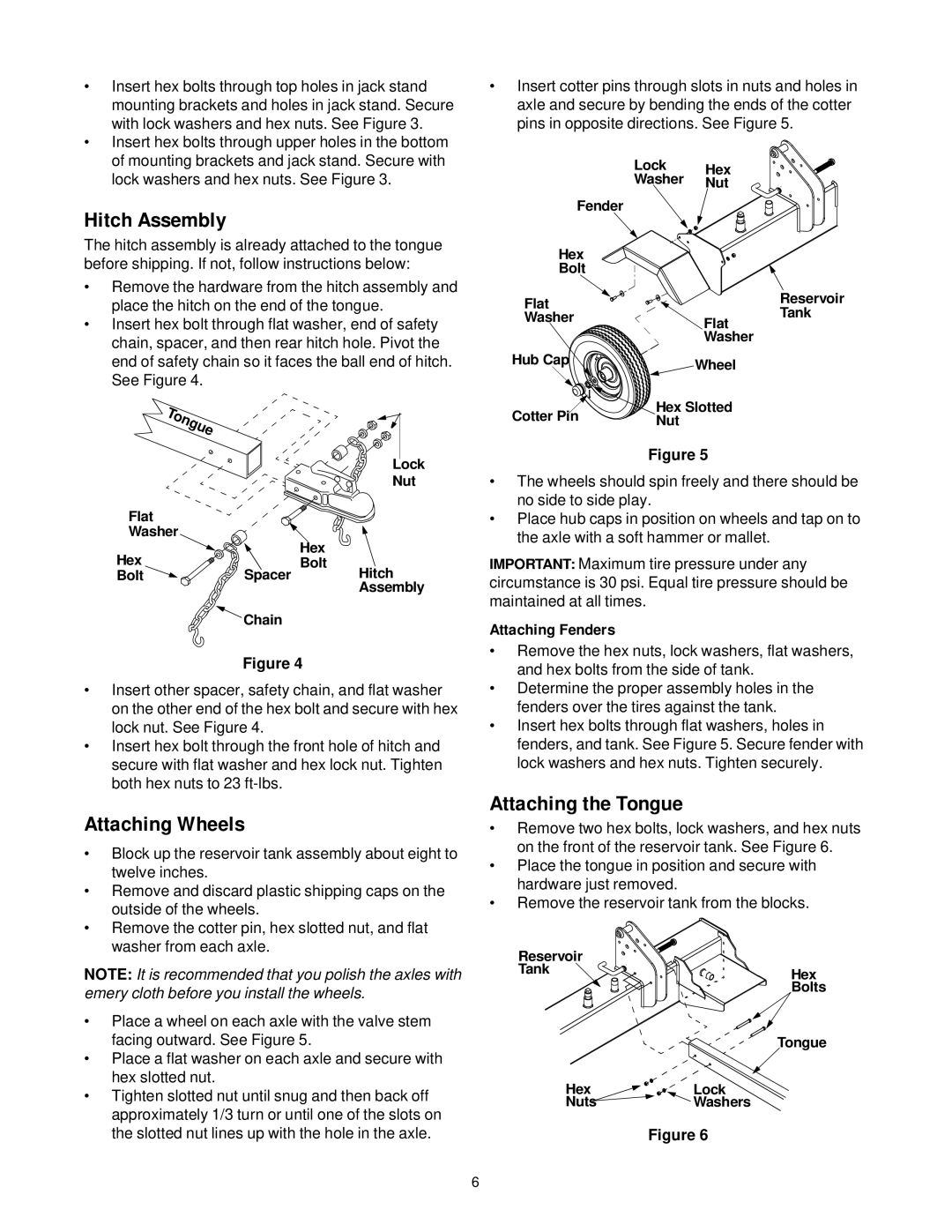

•Place a wheel on each axle with the valve stem facing outward. See Figure 5.

•Place a flat washer on each axle and secure with hex slotted nut.

•Tighten slotted nut until snug and then back off approximately 1/3 turn or until one of the slots on the slotted nut lines up with the hole in the axle.

•Insert cotter pins through slots in nuts and holes in axle and secure by bending the ends of the cotter pins in opposite directions. See Figure 5.

|

|

|

| Lock | Hex |

|

|

|

|

|

| |||||||||

|

|

|

| Washer |

|

| ||||||||||||||

|

|

|

| Nut |

|

|

| |||||||||||||

Fender |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Hex |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

Bolt |

|

|

|

|

|

|

|

|

|

|

| Reservoir | ||||||||

Flat |

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

| Tank | |||||||||

Washer |

|

|

|

|

|

|

|

|

|

|

| |||||||||

|

| Flat | ||||||||||||||||||

|

|

|

|

|

| Washer | ||||||||||||||

Hub Cap |

|

| Wheel | |||||||||||||||||

|

|

|

|

|

| |||||||||||||||

|

|

|

| Hex Slotted | ||||||||||||||||

|

|

|

| |||||||||||||||||

Cotter Pin | ||||||||||||||||||||

Nut |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

Figure 5

•The wheels should spin freely and there should be no side to side play.

•Place hub caps in position on wheels and tap on to the axle with a soft hammer or mallet.

IMPORTANT: Maximum tire pressure under any circumstance is 30 psi. Equal tire pressure should be maintained at all times.

Attaching Fenders

•Remove the hex nuts, lock washers, flat washers, and hex bolts from the side of tank.

•Determine the proper assembly holes in the fenders over the tires against the tank.

•Insert hex bolts through flat washers, holes in fenders, and tank. See Figure 5. Secure fender with lock washers and hex nuts. Tighten securely.

Attaching the Tongue

•Remove two hex bolts, lock washers, and hex nuts on the front of the reservoir tank. See Figure 6.

•Place the tongue in position and secure with hardware just removed.

•Remove the reservoir tank from the blocks.

Reservoir |

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| |||||||

Tank |

|

|

|

|

|

|

| Hex | ||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Bolts |

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Tongue |

Hex |

|

|

|

|

|

|

| |||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

|

|

| ||||||||

|

|

|

|

| Lock | |||||||||

|

|

|

|

| ||||||||||

Nuts |

|

|

|

|

| Washers | ||||||||

Figure 6

6