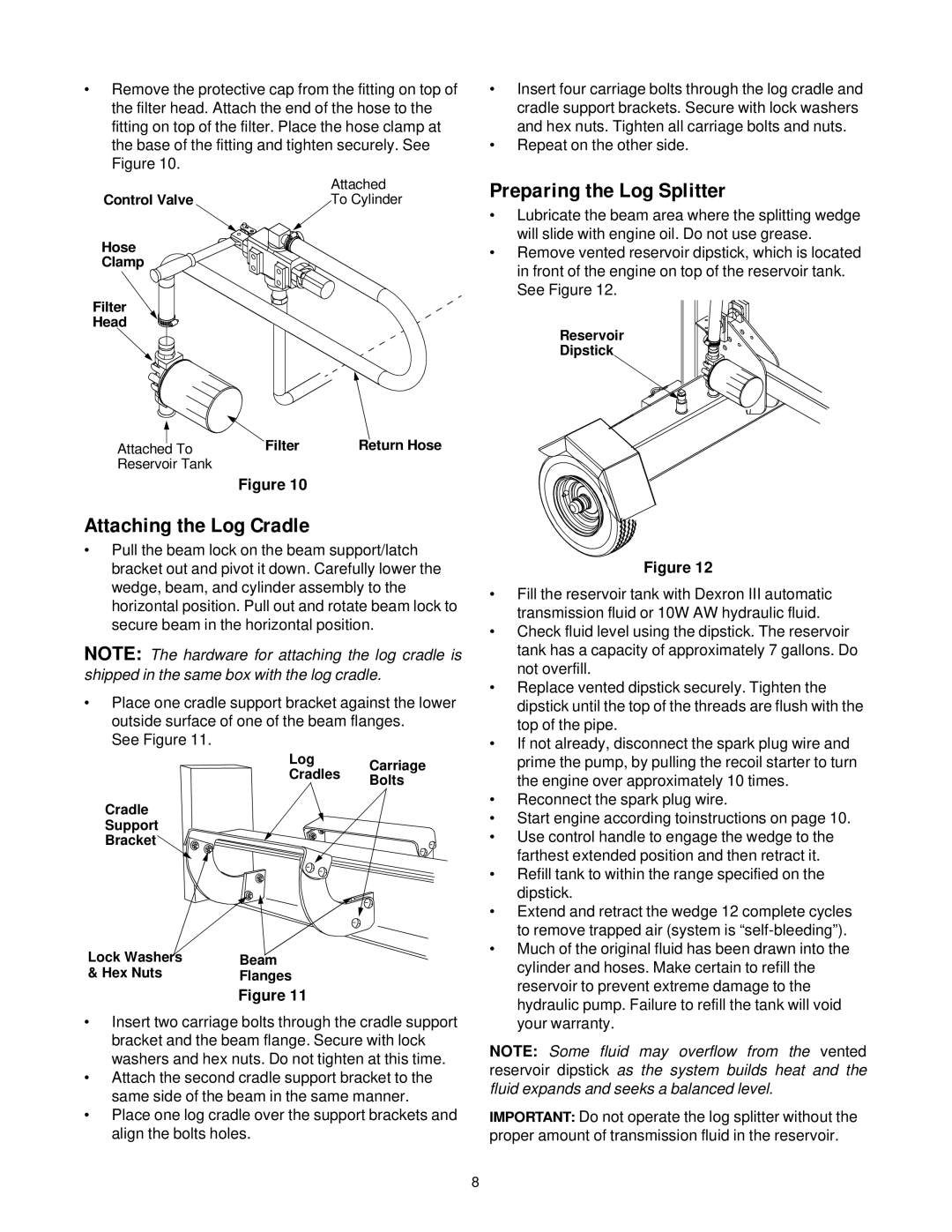

•Remove the protective cap from the fitting on top of the filter head. Attach the end of the hose to the fitting on top of the filter. Place the hose clamp at the base of the fitting and tighten securely. See Figure 10.

| Attached |

Control Valve | To Cylinder |

Hose

Clamp

Filter

Head

Attached |

| To | Filter | Return Hose |

| ||||

Reservoir Tank |

|

| ||

Figure 10

Attaching the Log Cradle

•Pull the beam lock on the beam support/latch bracket out and pivot it down. Carefully lower the wedge, beam, and cylinder assembly to the horizontal position. Pull out and rotate beam lock to secure beam in the horizontal position.

NOTE: The hardware for attaching the log cradle is shipped in the same box with the log cradle.

•Place one cradle support bracket against the lower outside surface of one of the beam flanges.

See Figure 11.

Log Carriage

Cradles Bolts

Cradle

Support

Bracket ![]()

Lock Washers | Beam |

& Hex Nuts | Flanges |

Figure 11

•Insert two carriage bolts through the cradle support bracket and the beam flange. Secure with lock washers and hex nuts. Do not tighten at this time.

•Attach the second cradle support bracket to the same side of the beam in the same manner.

•Place one log cradle over the support brackets and align the bolts holes.

•Insert four carriage bolts through the log cradle and cradle support brackets. Secure with lock washers and hex nuts. Tighten all carriage bolts and nuts.

•Repeat on the other side.

Preparing the Log Splitter

•Lubricate the beam area where the splitting wedge will slide with engine oil. Do not use grease.

•Remove vented reservoir dipstick, which is located in front of the engine on top of the reservoir tank. See Figure 12.

Reservoir

Dipstick

Figure 12

•Fill the reservoir tank with Dexron III automatic transmission fluid or 10W AW hydraulic fluid.

•Check fluid level using the dipstick. The reservoir tank has a capacity of approximately 7 gallons. Do not overfill.

•Replace vented dipstick securely. Tighten the dipstick until the top of the threads are flush with the top of the pipe.

•If not already, disconnect the spark plug wire and prime the pump, by pulling the recoil starter to turn the engine over approximately 10 times.

•Reconnect the spark plug wire.

•Start engine according toinstructions on page 10.

•Use control handle to engage the wedge to the farthest extended position and then retract it.

•Refill tank to within the range specified on the dipstick.

•Extend and retract the wedge 12 complete cycles to remove trapped air (system is

•Much of the original fluid has been drawn into the cylinder and hoses. Make certain to refill the reservoir to prevent extreme damage to the hydraulic pump. Failure to refill the tank will void your warranty.

NOTE: Some fluid may overflow from the vented reservoir dipstick as the system builds heat and the

fluid expands and seeks a balanced level.

IMPORTANT: Do not operate the log splitter without the proper amount of transmission fluid in the reservoir.

8