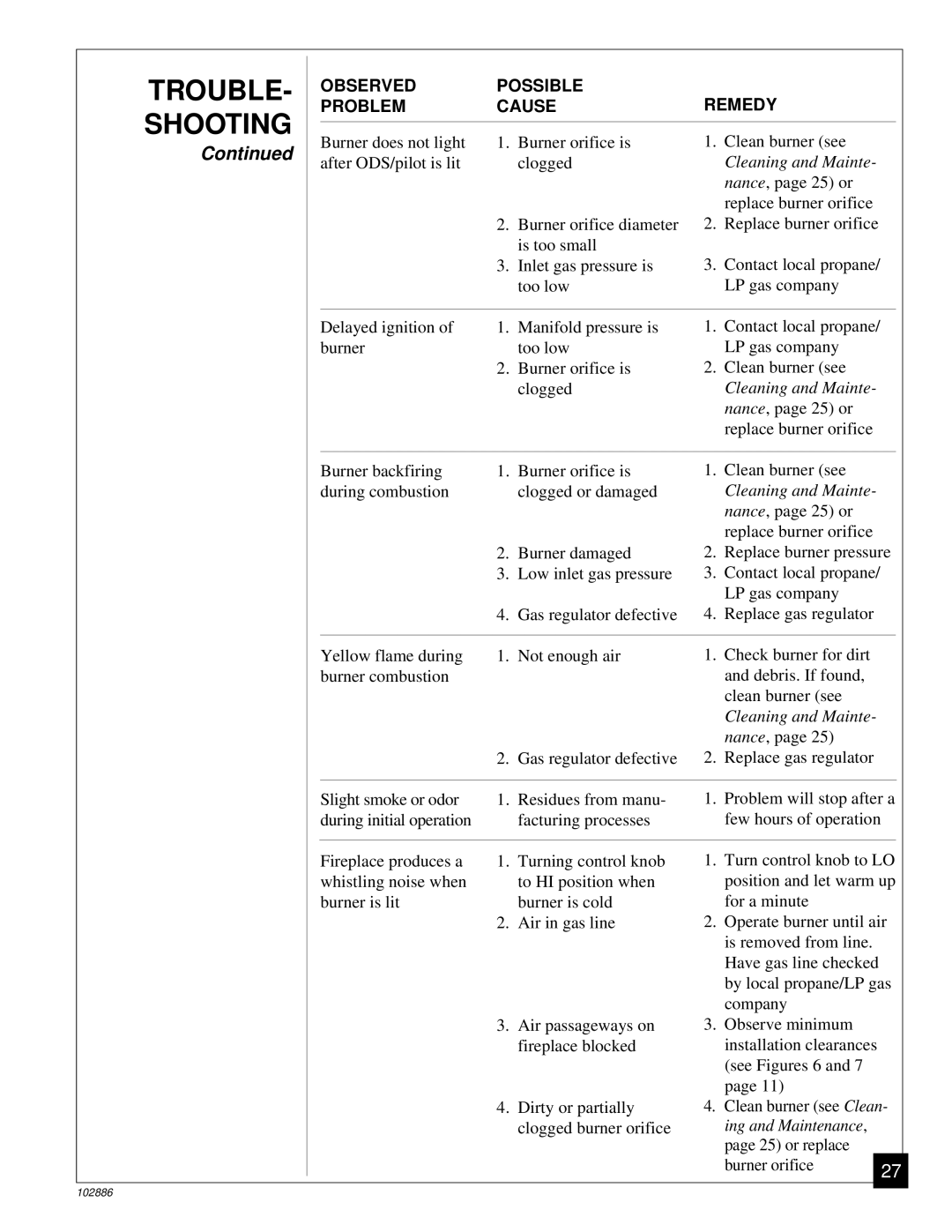

TROUBLE- SHOOTING

OBSERVED | POSSIBLE | REMEDY |

PROBLEM | CAUSE | |

|

|

|

Continued

Burner does not light | 1. | Burner orifice is |

after ODS/pilot is lit |

| clogged |

| 2. | Burner orifice diameter |

|

| is too small |

| 3. | Inlet gas pressure is |

|

| too low |

1.Clean burner (see Cleaning and Mainte- nance, page 25) or replace burner orifice

2.Replace burner orifice

3.Contact local propane/ LP gas company

Delayed ignition of | 1. | Manifold pressure is |

burner |

| too low |

| 2. | Burner orifice is |

|

| clogged |

1.Contact local propane/ LP gas company

2.Clean burner (see Cleaning and Mainte- nance, page 25) or replace burner orifice

Burner backfiring | 1. Burner orifice is |

during combustion | clogged or damaged |

2. Burner damaged

3. Low inlet gas pressure

4. Gas regulator defective

1.Clean burner (see Cleaning and Mainte- nance, page 25) or replace burner orifice

2.Replace burner pressure

3.Contact local propane/ LP gas company

4.Replace gas regulator

Yellow flame during | 1. Not enough air |

burner combustion |

|

2. Gas regulator defective

1.Check burner for dirt and debris. If found, clean burner (see Cleaning and Mainte- nance, page 25)

2.Replace gas regulator

Slight smoke or odor | 1. Residues from manu- | 1. Problem will stop after a |

during initial operation | facturing processes | few hours of operation |

|

|

|

Fireplace produces a | 1. | Turning control knob |

whistling noise when |

| to HI position when |

burner is lit |

| burner is cold |

| 2. | Air in gas line |

3. Air passageways on fireplace blocked

4. Dirty or partially clogged burner orifice

1.Turn control knob to LO position and let warm up for a minute

2.Operate burner until air is removed from line. Have gas line checked by local propane/LP gas company

3.Observe minimum installation clearances (see Figures 6 and 7 page 11)

4.Clean burner (see Clean- ing and Maintenance, page 25) or replace

burner orifice | 27 |

|

102886