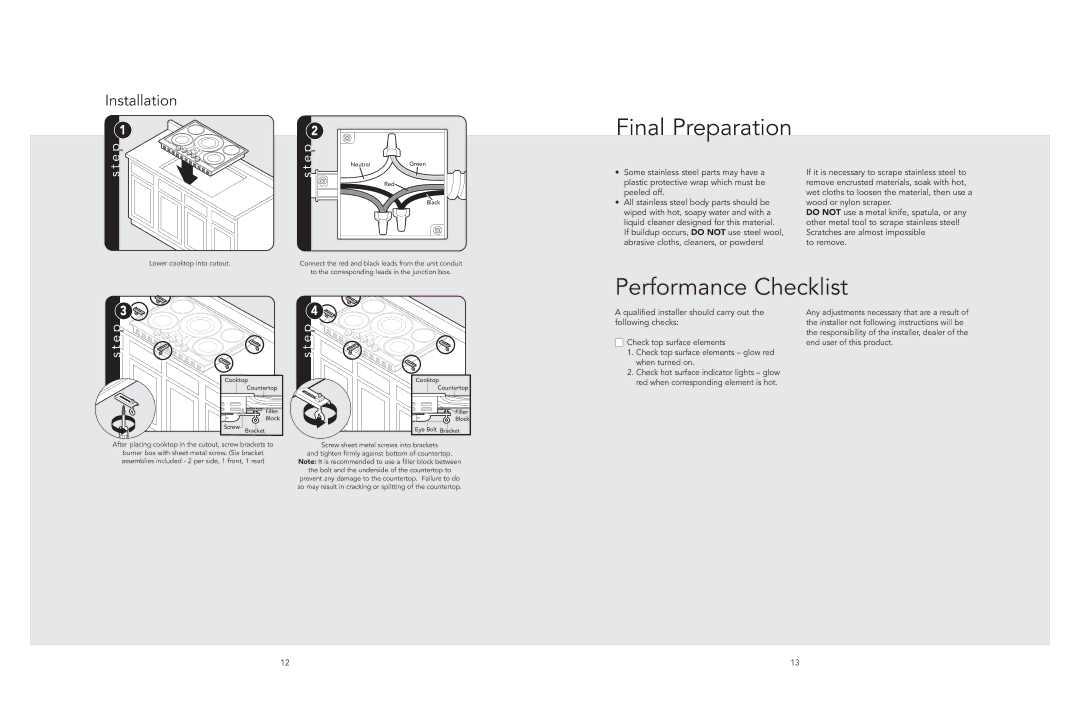

Installation

1 | 2 |

NeutralGreen

Final Preparation

Red

Black

Lower cooktop into cutout. | Connect the red and black leads from the unit conduit |

| to the corresponding leads in the junction box. |

•Some stainless steel parts may have a plastic protective wrap which must be peeled off.

•All stainless steel body parts should be wiped with hot, soapy water and with a liquid cleaner designed for this material.

If buildup occurs, DO NOT use steel wool, abrasive cloths, cleaners, or powders!

If it is necessary to scrape stainless steel to remove encrusted materials, soak with hot, wet cloths to loosen the material, then use a wood or nylon scraper.

DO NOT use a metal knife, spatula, or any other metal tool to scrape stainless steel! Scratches are almost impossible

to remove.

Performance Checklist

3 | 4 |

A qualified installer should carry out the following checks:

■ Check top surface elements | |

1. | Check top surface elements – glow red |

| when turned on. |

2. | Check hot surface indicator lights – glow |

Any adjustments necessary that are a result of the installer not following instructions will be the responsibility of the installer, dealer of the end user of this product.

Cooktop Countertop

![]()

![]()

![]()

![]()

![]()

![]() Filler

Filler

Block

Screw Bracket

Cooktop |

Countertop |

Filler |

Block |

Eye Bolt Bracket |

red when corresponding element is hot. |

After placing cooktop in the cutout, screw brackets to | Screw sheet metal screws into brackets |

burner box with sheet metal screw. (Six bracket | and tighten firmly against bottom of countertop. |

assemblies included - 2 per side, 1 front, 1 rear) | Note: It is recommended to use a filler block between |

| the bolt and the underside of the countertop to |

| prevent any damage to the countertop. Failure to do |

| so may result in cracking or splitting of the countertop. |

12 | 13 |