Fryers specifications

Vulcan-Hart fryers have established themselves as a staple in commercial kitchens across the globe, renowned for their durability, efficiency, and innovative technology. These fryers cater to the diverse needs of restaurants, food trucks, and any establishment focused on delivering high-quality fried foods with consistent results.One of the main features of Vulcan-Hart fryers is their robust construction. Made from high-grade stainless steel, these fryers are designed to withstand the rigors of a busy kitchen environment. This material not only enhances durability but also aids in easy cleaning, ensuring hygiene standards are met without compromising efficiency.

Vulcan-Hart fryers come with various capacities, accommodating establishments of all sizes. From countertop models suited for smaller operations to larger floor models ideal for high-volume frying, there is a Vulcan-Hart fryer to match every kitchen's needs. The fryers are available with single or double fry pots, enabling versatility in cooking multiple items simultaneously.

In terms of technology, Vulcan-Hart fryers are equipped with advanced heating elements that ensure rapid recovery times and even heat distribution. This feature is crucial for maintaining consistent frying temperatures, resulting in perfectly cooked foods every time. Many models are designed with auto-thermostats that regulate temperature, reducing the chance of oil degradation and ensuring optimal frying conditions.

Energy efficiency is another characteristic that sets Vulcan-Hart fryers apart. With features such as high-efficiency gas burners and oil management systems, these fryers minimize energy consumption while maximizing output. This commitment to sustainability not only benefits the environment but also contributes to cost savings for the business.

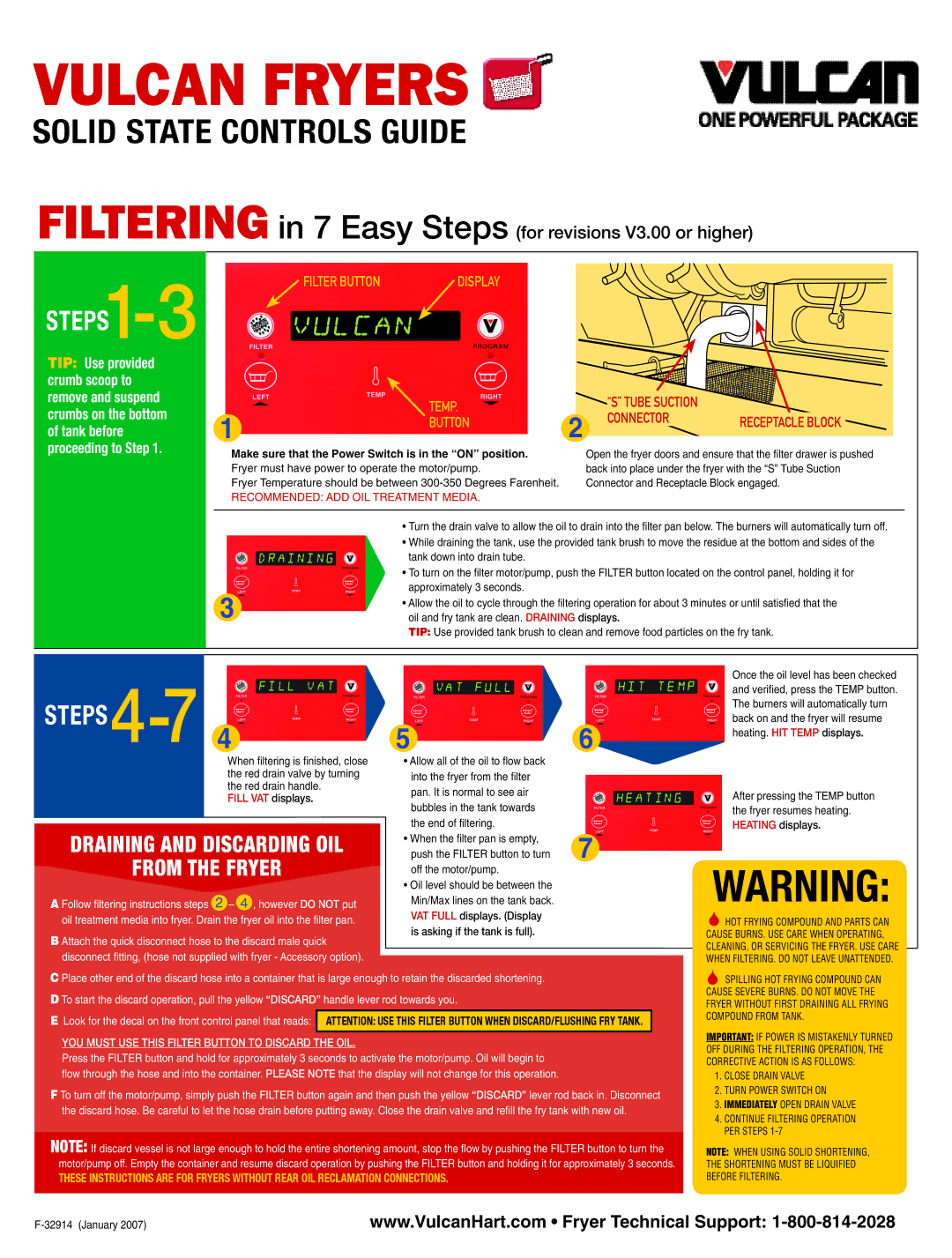

Safety features are paramount in the design of Vulcan-Hart fryers. Many models include built-in safeguards, such as automatic shut-off systems and cool-to-the-touch exteriors, protecting staff from burns and accidents. The fryers also have well-designed oil filtration systems that prolong the life of the cooking oil, enhancing food quality and reducing waste.

In summary, Vulcan-Hart fryers are a blend of durability, efficiency, and advanced technology, making them a trusted choice for commercial kitchens. With features designed for performance and safety, they remain a valuable asset for chefs and foodservice operators looking to deliver exceptional fried foods while maintaining operational excellence.