EDITION 07 /2005 | PART NO. DOC0350941 |

OPERATING MANUAL

GA 250AL_GA 400AL.

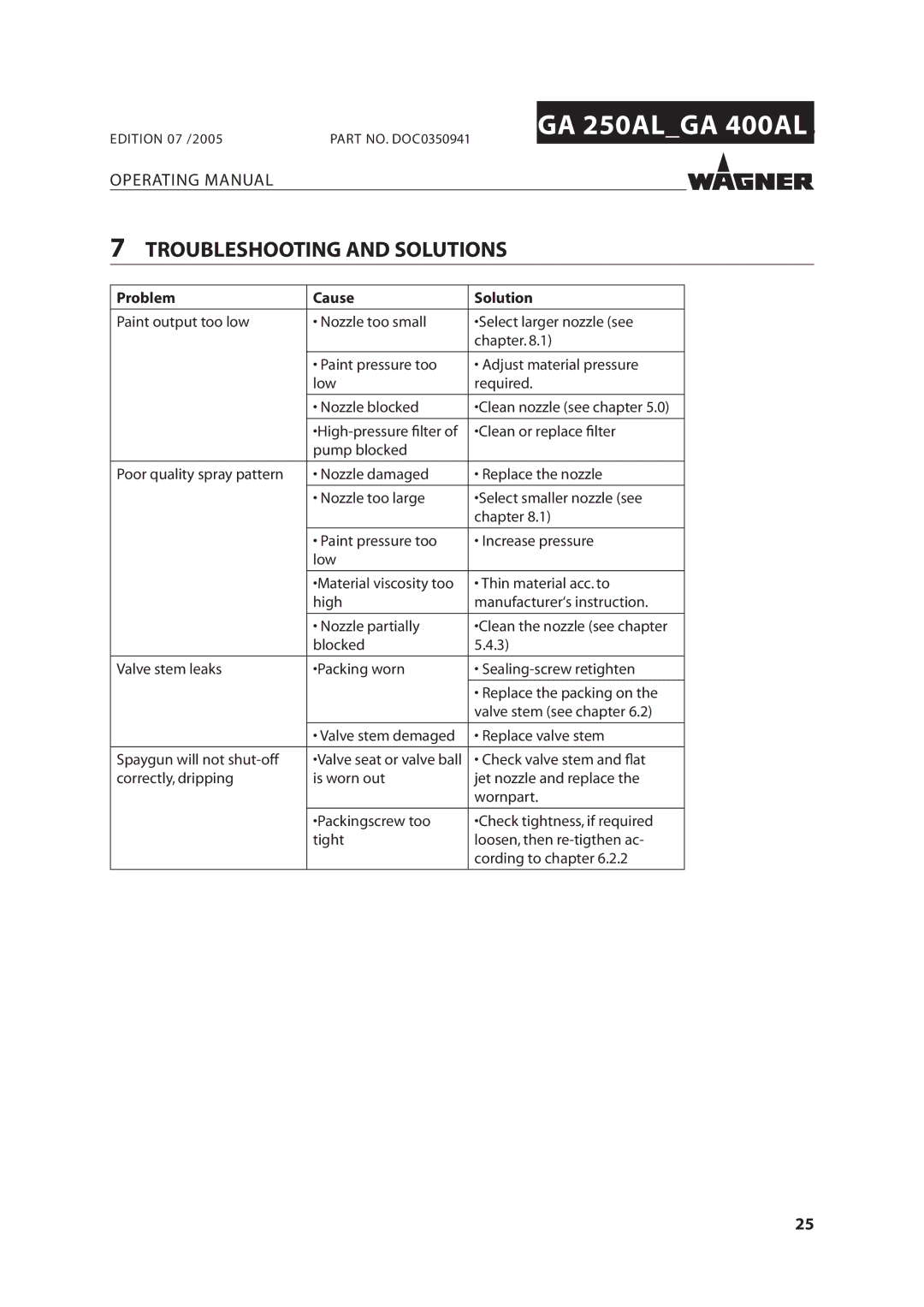

7 TROUBLESHOOTING AND SOLUTIONS

Problem | Cause | Solution |

|

|

|

Paint output too low | • Nozzle too small | •Select larger nozzle (see |

|

| chapter. 8.1) |

| • Paint pressure too | • Adjust material pressure |

| low | required. |

|

|

|

| • Nozzle blocked | •Clean nozzle (see chapter 5.0) |

|

|

|

| •Clean or replace filter | |

| pump blocked |

|

Poor quality spray pattern | • Nozzle damaged | • Replace the nozzle |

|

|

|

| • Nozzle too large | •Select smaller nozzle (see |

|

| chapter 8.1) |

|

|

|

| • Paint pressure too | • Increase pressure |

| low |

|

| •Material viscosity too | • Thin material acc. to |

| high | manufacturer‘s instruction. |

|

|

|

| • Nozzle partially | •Clean the nozzle (see chapter |

| blocked | 5.4.3) |

|

|

|

Valve stem leaks | •Packing worn | • |

|

| • Replace the packing on the |

|

| valve stem (see chapter 6.2) |

|

|

|

| • Valve stem demaged | • Replace valve stem |

|

|

|

Spaygun will not | •Valve seat or valve ball | • Check valve stem and flat |

correctly, dripping | is worn out | jet nozzle and replace the |

|

| wornpart. |

| •Packingscrew too | •Check tightness, if required |

| tight | loosen, then |

|

| cording to chapter 6.2.2 |

|

|

|

25