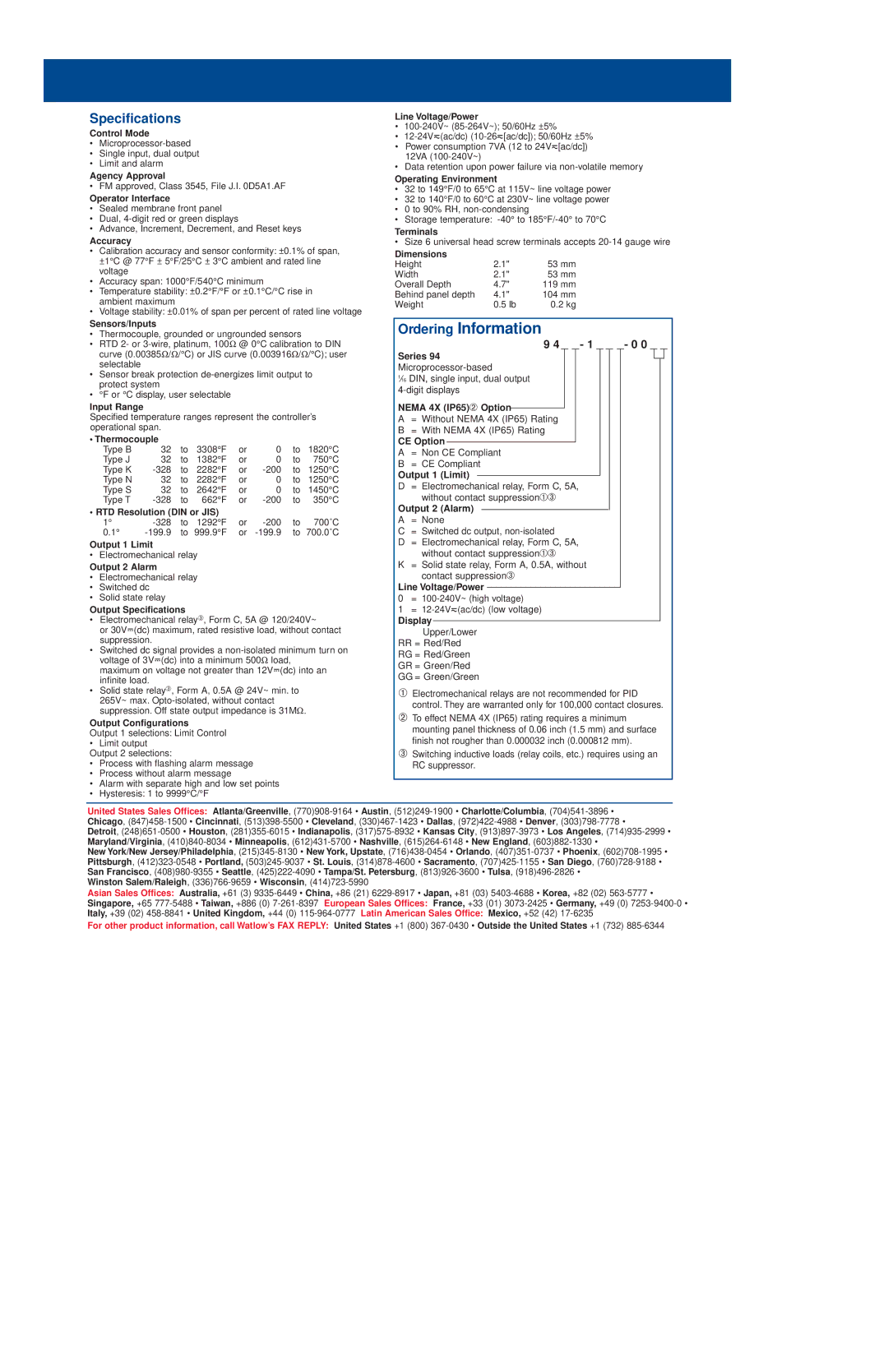

Series 94 specifications

Watlow Electric, a renowned leader in the thermal control industry, offers a versatile and advanced solution with its Series 94 controllers. These controllers are designed for a wide range of industrial applications, providing precise temperature control that is crucial for maintaining operational efficiency and product quality.One of the primary features of the Series 94 is its user-friendly interface. The controllers are equipped with a large, bright display that allows operators to easily view and adjust process parameters. The intuitive menu-driven setup makes it accessible for both experienced technicians and those new to thermal management systems. The front panel features fully programmable keys, enabling quick access to frequently used functions, thereby enhancing productivity.

In terms of technology, the Series 94 utilizes state-of-the-art control algorithms that optimize temperature regulation while minimizing overshoot and instability. This precision is achieved through PID (Proportional-Integral-Derivative) control, which continuously adjusts the heating output based on real-time temperature feedback. This results in greater energy efficiency and a reduced carbon footprint for industrial processes.

Another significant characteristic of the Series 94 is its versatility. It offers multiple control modes, including ON/OFF, PID, and advanced control options for applications requiring superior performance. Additionally, it supports a variety of thermocouple and RTD input types, making it compatible with a wide range of temperature sensing devices. This flexibility allows users to implement the Series 94 in diverse applications, from ovens and furnaces to plastics processing and food production.

The durability of the Series 94 is another notable aspect. Built to withstand the rigors of industrial environments, it features robust housing and components capable of functioning optimally in demanding conditions. This reliability, combined with its superior temperature control capabilities, ensures that production processes run smoothly and efficiently.

Furthermore, the Series 94 incorporates advanced communication protocols, including Modbus and Ethernet, allowing for easy integration into existing industrial automation systems. This connectivity enables remote monitoring and control, enhancing operational oversight and responsiveness.

In conclusively, the Watlow Electric Series 94 stands out in the market for its advanced features, user-friendly design, versatile applications, and durable construction. These characteristics make it a trusted solution for industries seeking reliable and precise thermal management systems. Whether for process heating or temperature control, the Series 94 delivers performance that meets the demands of modern industrial applications.