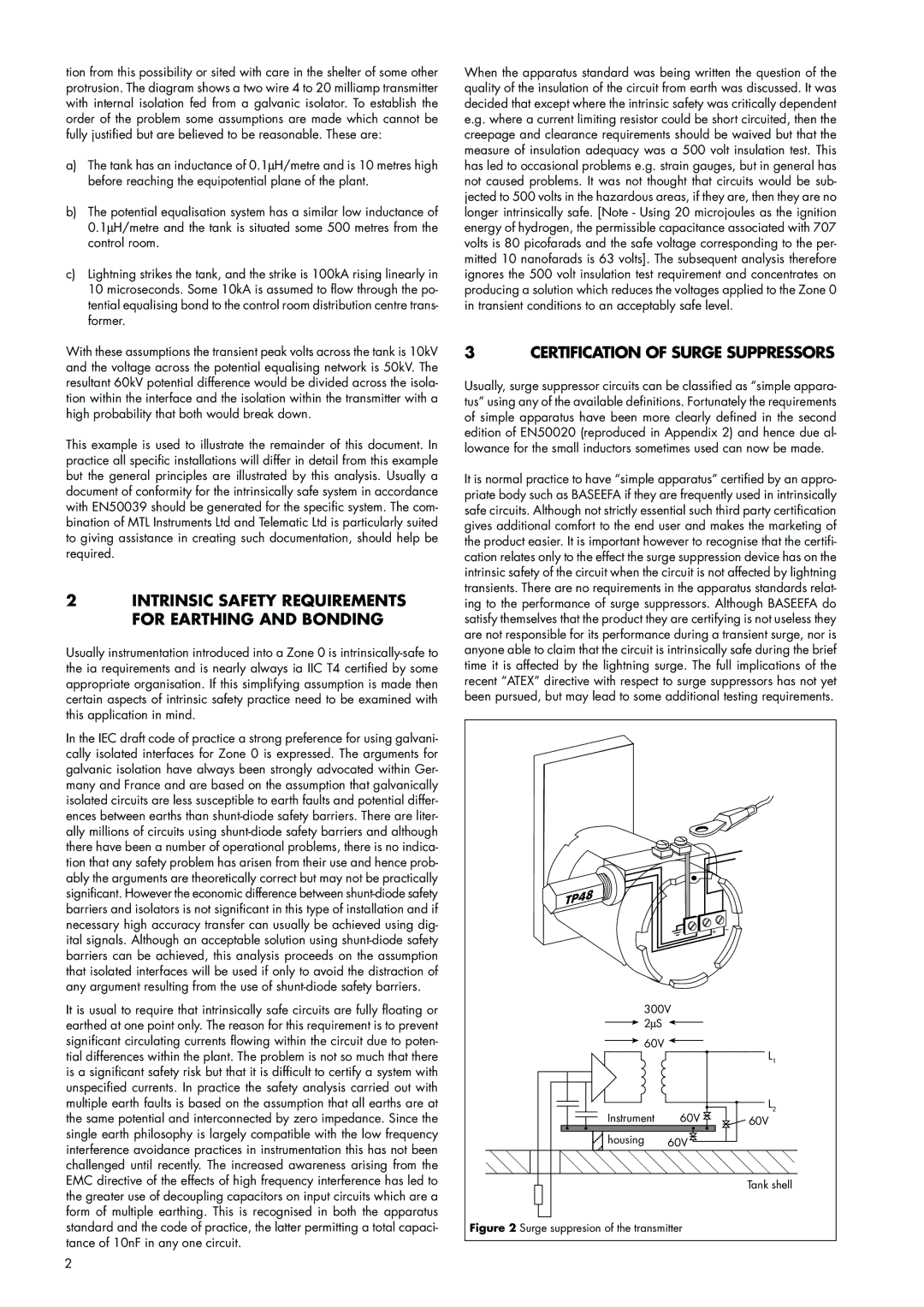

tion from this possibility or sited with care in the shelter of some other protrusion. The diagram shows a two wire 4 to 20 milliamp transmitter with internal isolation fed from a galvanic isolator. To establish the order of the problem some assumptions are made which cannot be fully justified but are believed to be reasonable. These are:

a)The tank has an inductance of 0.1μH/metre and is 10 metres high before reaching the equipotential plane of the plant.

b)The potential equalisation system has a similar low inductance of 0.1μH/metre and the tank is situated some 500 metres from the control room.

c)Lightning strikes the tank, and the strike is 100kA rising linearly in 10 microseconds. Some 10kA is assumed to flow through the po- tential equalising bond to the control room distribution centre trans- former.

With these assumptions the transient peak volts across the tank is 10kV and the voltage across the potential equalising network is 50kV. The resultant 60kV potential difference would be divided across the isola- tion within the interface and the isolation within the transmitter with a high probability that both would break down.

This example is used to illustrate the remainder of this document. In practice all specific installations will differ in detail from this example but the general principles are illustrated by this analysis. Usually a document of conformity for the intrinsically safe system in accordance with EN50039 should be generated for the specific system. The com- bination of MTL Instruments Ltd and Telematic Ltd is particularly suited to giving assistance in creating such documentation, should help be required.

2INTRINSIC SAFETY REQUIREMENTS FOR EARTHING AND BONDING

Usually instrumentation introduced into a Zone 0 is

In the IEC draft code of practice a strong preference for using galvani- cally isolated interfaces for Zone 0 is expressed. The arguments for galvanic isolation have always been strongly advocated within Ger- many and France and are based on the assumption that galvanically isolated circuits are less susceptible to earth faults and potential differ- ences between earths than

It is usual to require that intrinsically safe circuits are fully floating or earthed at one point only. The reason for this requirement is to prevent significant circulating currents flowing within the circuit due to poten- tial differences within the plant. The problem is not so much that there is a significant safety risk but that it is difficult to certify a system with unspecified currents. In practice the safety analysis carried out with multiple earth faults is based on the assumption that all earths are at the same potential and interconnected by zero impedance. Since the single earth philosophy is largely compatible with the low frequency interference avoidance practices in instrumentation this has not been challenged until recently. The increased awareness arising from the EMC directive of the effects of high frequency interference has led to the greater use of decoupling capacitors on input circuits which are a form of multiple earthing. This is recognised in both the apparatus standard and the code of practice, the latter permitting a total capaci- tance of 10nF in any one circuit.

When the apparatus standard was being written the question of the quality of the insulation of the circuit from earth was discussed. It was decided that except where the intrinsic safety was critically dependent e.g. where a current limiting resistor could be short circuited, then the creepage and clearance requirements should be waived but that the measure of insulation adequacy was a 500 volt insulation test. This has led to occasional problems e.g. strain gauges, but in general has not caused problems. It was not thought that circuits would be sub- jected to 500 volts in the hazardous areas, if they are, then they are no longer intrinsically safe. [Note - Using 20 microjoules as the ignition energy of hydrogen, the permissible capacitance associated with 707 volts is 80 picofarads and the safe voltage corresponding to the per- mitted 10 nanofarads is 63 volts]. The subsequent analysis therefore ignores the 500 volt insulation test requirement and concentrates on producing a solution which reduces the voltages applied to the Zone 0 in transient conditions to an acceptably safe level.

3 CERTIFICATION OF SURGE SUPPRESSORS

Usually, surge suppressor circuits can be classified as “simple appara- tus” using any of the available definitions. Fortunately the requirements of simple apparatus have been more clearly defined in the second edition of EN50020 (reproduced in Appendix 2) and hence due al- lowance for the small inductors sometimes used can now be made.

It is normal practice to have “simple apparatus” certified by an appro- priate body such as BASEEFA if they are frequently used in intrinsically safe circuits. Although not strictly essential such third party certification gives additional comfort to the end user and makes the marketing of the product easier. It is important however to recognise that the certifi- cation relates only to the effect the surge suppression device has on the intrinsic safety of the circuit when the circuit is not affected by lightning transients. There are no requirements in the apparatus standards relat- ing to the performance of surge suppressors. Although BASEEFA do satisfy themselves that the product they are certifying is not useless they are not responsible for its performance during a transient surge, nor is anyone able to claim that the circuit is intrinsically safe during the brief time it is affected by the lightning surge. The full implications of the recent “ATEX” directive with respect to surge suppressors has not yet been pursued, but may lead to some additional testing requirements.

| + | – |

300V |

| |

2μS |

|

|

60V |

| L1 |

|

| |

Instrument | 60V | L2 |

60V | ||

housing | 60V |

|

|

| Tank shell |

Figure 2 Surge suppresion of the transmitter |

| |

2