INSTALLATION AND FRAMING INSTRUCTIONS

The variety of installations possible for this whirlpool may require framing procedures other than those shown. Locate studs as needed. Ensure

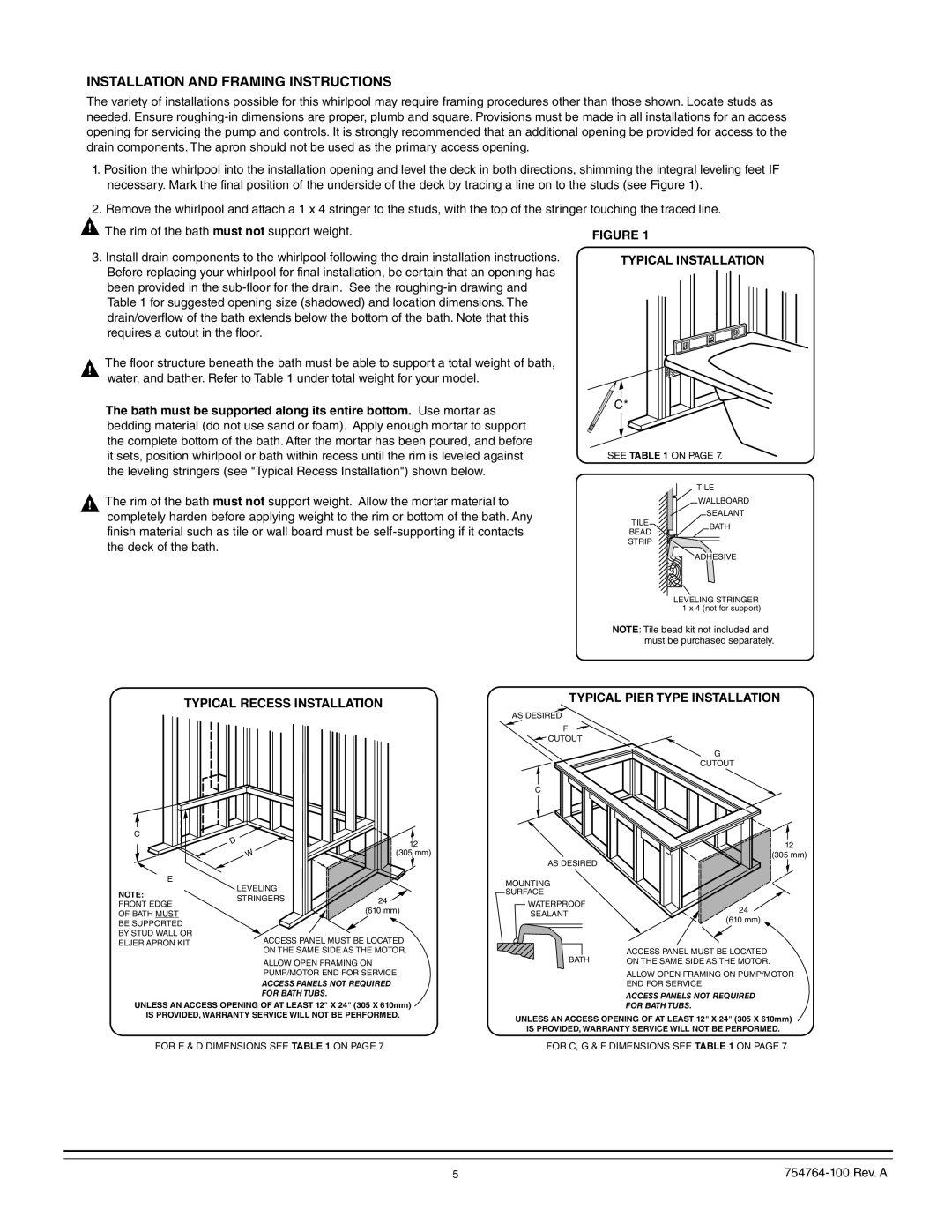

1.Position the whirlpool into the installation opening and level the deck in both directions, shimming the integral leveling feet IF necessary. Mark the final position of the underside of the deck by tracing a line on to the studs (see Figure 1).

2.Remove the whirlpool and attach a 1 x 4 stringer to the studs, with the top of the stringer touching the traced line.

!The rim of the bath must not support weight.

3.Install drain components to the whirlpool following the drain installation instructions. Before replacing your whirlpool for final installation, be certain that an opening has been provided in the

The floor structure beneath the bath must be able to support a total weight of bath,

!

water, and bather. Refer to Table 1 under total weight for your model.

The bath must be supported along its entire bottom. Use mortar as bedding material (do not use sand or foam). Apply enough mortar to support the complete bottom of the bath. After the mortar has been poured, and before it sets, position whirlpool or bath within recess until the rim is leveled against the leveling stringers (see "Typical Recess Installation") shown below.

!The rim of the bath must not support weight. Allow the mortar material to completely harden before applying weight to the rim or bottom of the bath. Any finish material such as tile or wall board must be

FIGURE 1

TYPICAL INSTALLATION

C*

SEE TABLE 1 ON PAGE 7.

| TILE | |

| WALLBOARD | |

TILE | SEALANT | |

BATH | ||

BEAD | ||

| ||

STRIP |

| |

| ADHESIVE |

LEVELING STRINGER 1 x 4 (not for support)

NOTE: Tile bead kit not included and must be purchased separately.

TYPICAL RECESS INSTALLATION

TYPICAL PIER TYPE INSTALLATION

AS DESIRED

F

![]() CUTOUT

CUTOUT

C

![]() G CUTOUT

G CUTOUT

C

E

NOTE:

FRONT EDGE

OF BATH MUST BE SUPPORTED BY STUD WALL OR ELJER APRON KIT

D | 12 |

W | (305 mm) |

LEVELING |

|

STRINGERS | 24 |

| (610 mm) |

ACCESS PANEL MUST BE LOCATED

ON THE SAME SIDE AS THE MOTOR.

ALLOW OPEN FRAMING ON

PUMP/MOTOR END FOR SERVICE.

ACCESS PANELS NOT REQUIRED

FOR BATH TUBS.

AS DESIRED

MOUNTING

SURFACE

WATERPROOF SEALANT

BATH

12

(305 mm)

24

(610 mm)

ACCESS PANEL MUST BE LOCATED ON THE SAME SIDE AS THE MOTOR.

ALLOW OPEN FRAMING ON PUMP/MOTOR END FOR SERVICE.

ACCESS PANELS NOT REQUIRED

UNLESS AN ACCESS OPENING OF AT LEAST 12" X 24" (305 X 610mm)

IS PROVIDED, WARRANTY SERVICE WILL NOT BE PERFORMED.

FOR E & D DIMENSIONS SEE TABLE 1 ON PAGE 7.

FOR BATH TUBS.

UNLESS AN ACCESS OPENING OF AT LEAST 12" X 24" (305 X 610mm)

IS PROVIDED, WARRANTY SERVICE WILL NOT BE PERFORMED.

FOR C, G & F DIMENSIONS SEE TABLE 1 ON PAGE 7.

5 |