Electrical requirements

Electrical Shock Hazard Electrical ground is required.

Do Not ground to a gas supply pipe.

Do Not change the power supply cord plug. If it does not fit the outlet, have a proper outlet installed by a qualified electrician.

Do Not have a fuse in the neutral or grounding circuit.

Check with a qualified electrician if you are not sure the ice maker is properly grounded.

Electrical wiring, water supply line and drain line must not contact any exposed terminals of the ice maker wiring.

Failure to follow these instructions could result in death or serious injury.

If codes permit and a separate ground- ing wire is used, it is recommended that a qualified electrician determine that the grounding pafh is adequate.

A 120-volt, 60-Hz, AC-only, 15 or

20-ampere, fused, electrical supply is required. Time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit serving only this ice maker be provided

Recommended grounded method

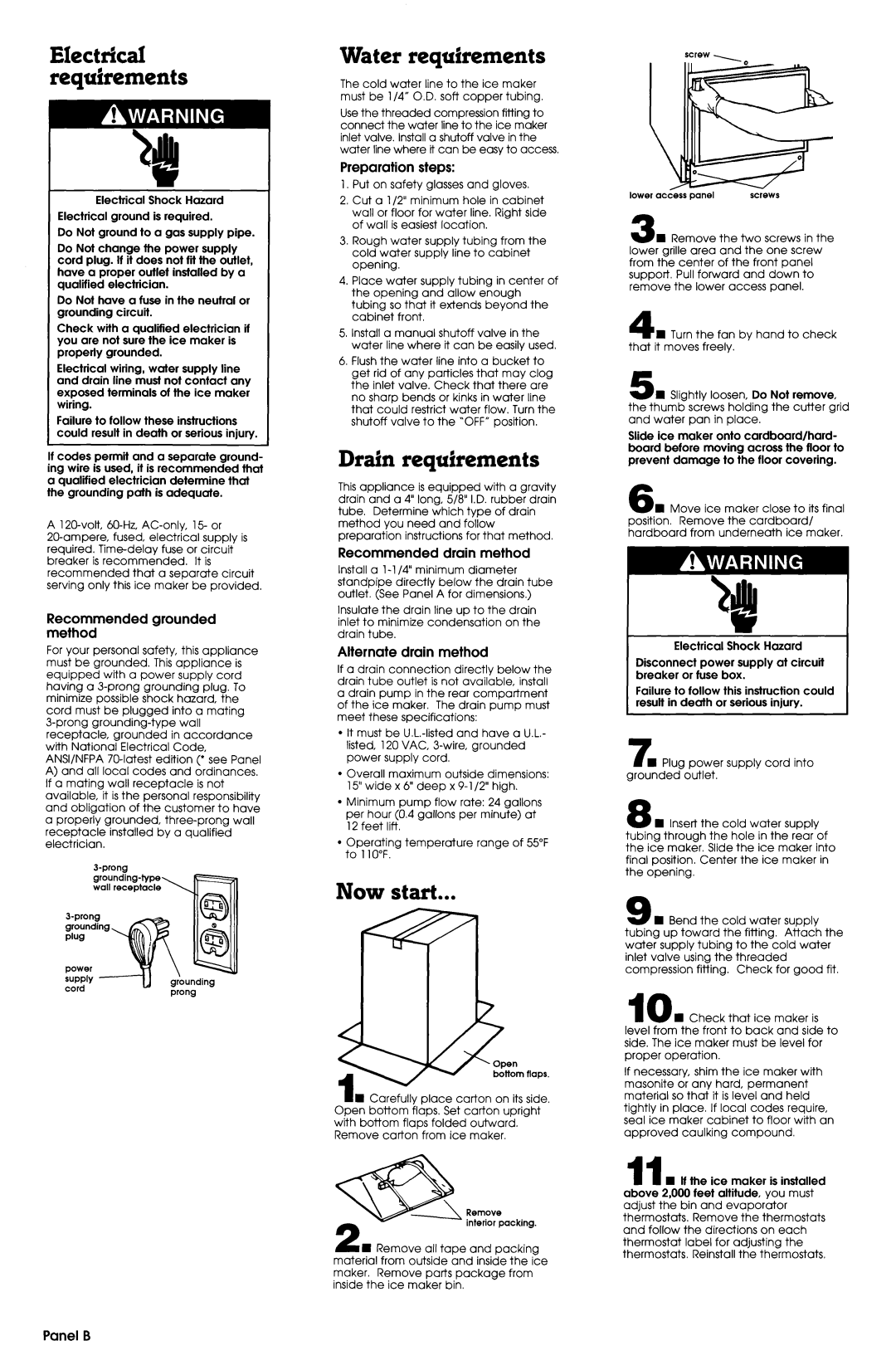

For your personal safety, this appliance must be grounded. This appliance is equipped with a power supply cord having a 3-prong grounding plug. To minimize possible shock hazard, the cord must be plugged into a mating 3-prong grounding-type wall receptacle, grounded in accordance with National Electrical Code, ANSl/NFPA 70-latest edition (* see Panel

A)and all local codes and ordinances. If 0 mating wall receptacle is not available, it is the personal responsibility and obligation of the customer to have a properly grounded, three-prong wall receptacle installed by a qualified electrician.

3-prong

Water requirements

The cold water line to the ice maker must be l/4” O.D. soft copper tubing.

Use the threaded compression fitting to connect the water line to the ice maker inlet valve. Install a shutoff valve in the water line where it can be easy to access

Preparation steps:

1aPut on safety glasses and gloves.

2.Cut a l/2” minimum hole in cabinet wall or floor for water line. Right side of wall is easiest location.

3.Rough water supply tubing from the cold water supply line to cabinet opening.

4.Place water supply tubing in center of the opening and allow enough

tubing so that it extends beyond the cabinet front.

5.Install a manual shutoff valve in the water line where it can be easily used,

6.Flush the water line into a bucket to get rid of any particles that may clog the inlet valve. Check that there are no sharp bends or kinks in water line that could restrict water flow. Turn the shutoff valve to the “OFF”position.

Drain requirements

This appliance is equipped with a gravity drain and a 4” long, 5/8” I.D. rubber drain tube. Determine which type of drain method you need and follow preparation instructions for that method.

Recommended drain method

Install a l-l /4” minimum diameter standpipe directly below the drain tube outlet. (See Panel A for dimensions.)

Insulate the drain line up to the drain inlet to minimize condensation on the drain tube.

Alternate drain method

If a drain connection directly below the drain tube outlet is not available, install a drain pump in the rear compartment of the ice maker. The drain pump must meet these specifications:

lIt must be U.L.-listed and have a U.L.- listed, 120 VAC, 3-wire, grounded power supply cord.

l Overall maximum outside dimensions: 15” wide x 6” deep x 9-l /2” high.

l Minimum pump flow rate: 24 gallons per hour (0.4 gallons per minute) at 12 feet lift

l Operating temperature range of 55°F to 110°F.

Now start...

n Carefullv place carton on its side. Open bottom flaps. Set carton upright with bottom flaps folded outward. Remove carton from ice maker.

| | | \ |

* | \\ | A | Remove |

| | | interior packing. |

n

L; H Remove all tape and packing material from outside and inside the ice maker. Remove parts package from inside the ice maker bin.

screw .

3 n Remove the two screws in the lower grille area and the one screw from the center of the front panel support. Pull forward and down to remove the lower access panel.

4 n Turn the fan by hand to check that it moves freely.

5 n Slightly loosen, Do Not remove, the thumb screws holding the cutter grid and water pan in place.

Slide ice maker onto cardboard/hard- board before moving across the floor to prevent damage to the floor covering.

6 n Move ice maker close to its final position. Remove the cardboard/ hardboard from underneath ice maker.

Electrical Shock Hazard

Disconnect power supply at circuit breaker or fuse box.

Failure to follow this instruction could result in death or serious injury.

L

7n Plug power supply cord into grounded outlet.

8n Insert the cold water supply tubing through the hole in the rear of the ice maker. Slide the ice maker into final position. Center the ice maker in the opening.

9n Bend the cold water supply tubing up toward the fitting. Attach the water supply tubing to the cold water inlet valve using the threaded compression fitting. Check for good fit.

10 n Check that ice maker is level from the front to back and side to side. The ice maker must be level for proper operation.

If necessary, shim the ice maker with masonite or any hard, permanent material so that it is level and held tightly in place. If local codes require, seal ice maker cabinet to floor with an approved caulking compound.

11n If the ice maker is installed above 2,000 feet altitude, you must adjust the bin and evaporator thermostats. Remove the thermostats and follow the directions on each thermostat label for adjusting the thermostats. Reinstall the thermostats,