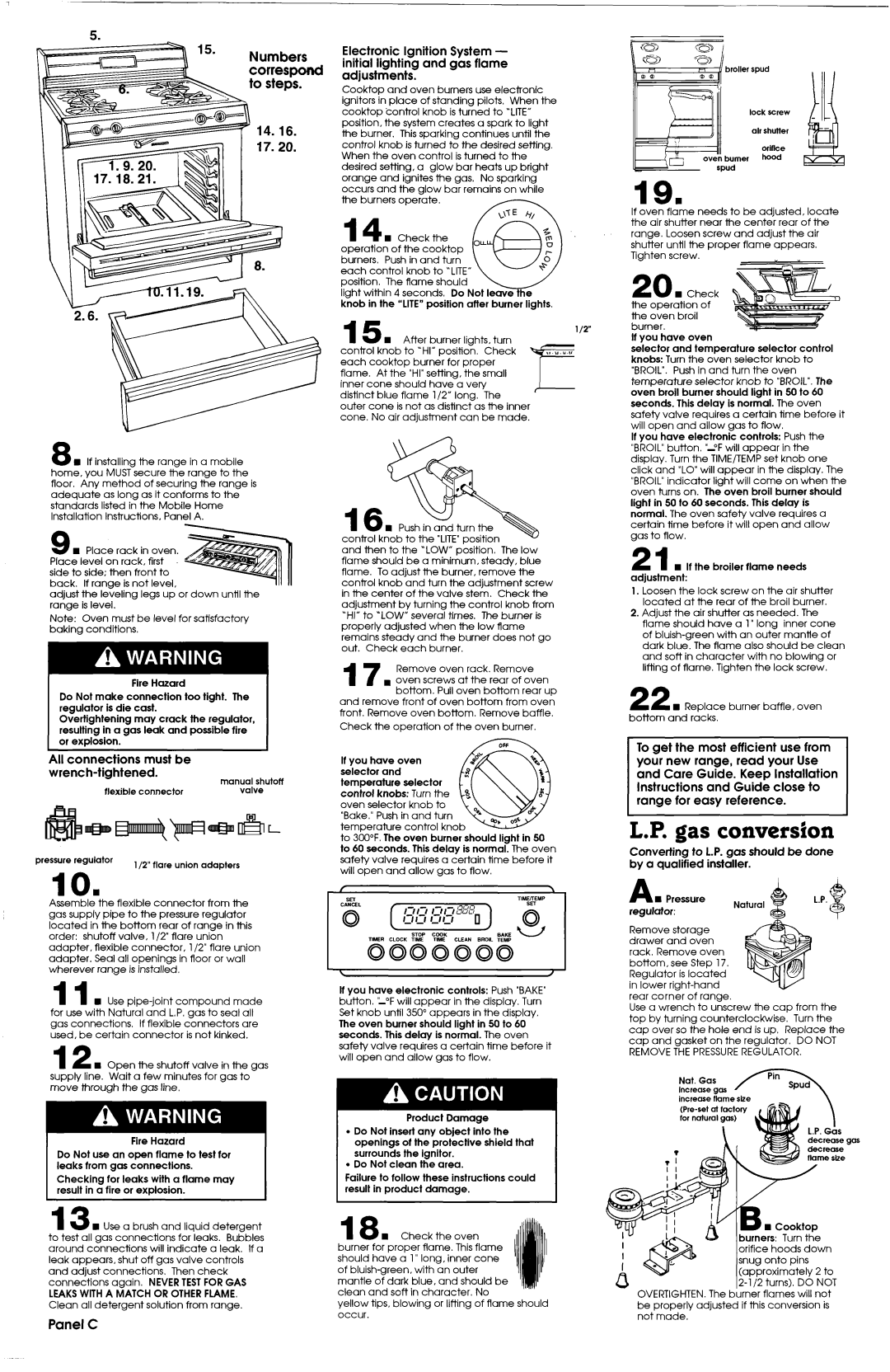

8n If installina the ranae in a mobile home, you MUST&cure Ge range to the floor. Any method of securing the range is adequate as long as it conforms to the standards listed in the Mobile Home Installation Instructions. Panel A.

n Place rack in oven Y4+?$

Place level on rack, first - side to side; then front to

back. If range is not level,111 II adjust the leveling legs up or down until the

range is level.

Note: Oven must be level for satisfactory baking conditions.

Do Not make connection too tight. The

All connections | must be |

|

|

| manual shutoff |

|

| |

flexible | connector | valve |

pressure regulator l/2” flare union adapters

10.

Assemble the flexible connector from the

Electronic Ignition System - initial lighting and gas flame adjustments.

Cooktop and oven burners use electronic ignitors in place of standing pilots. When the cooktop control knob is turned to “LITE” position, the system creates a spark to light the burner. This sparking continues until the control knob is turned to the desired setting. When the oven control is turned to the desired setting, a glow bar heats up bright orange and ignites the gas. No sparking occurs and the glow bar remains on while the burners operate.

14 n Check the operation of the cooktop burners. Push in and turn each control knob to “LITE” position. The flame should w

light within 4 seconds. Do Not leave the knob in the “LITE”position after burner lights.

15 n After burner lights, turn control knob to ‘HI” position. Check each cooktop burner for proper flame. At the “HI”setting, the small inner cone should have a very distinct blue flame l/2” long. The outer cone is not as distinct as the inner cone. No air adjustment can be made.

16

control knob to the “LITE”position

and then to the ‘LOW” position. The low flame should be a minimum, steady, blue flame. To adjust the burner, remove the control knob and turn the adjustment screw in the center of the valve stem. Check the adjustment by turning the control knob from ‘HI” to “LOW” several times. The burner is properly adjusted when the low flame remains steady and the burner does not go out. Check each burner.

17 Remove oven rack. Remove

. oven screws at the rear of oven bottom. Pull oven bottom rear up

and remove front of oven bottom from oven front. Remove oven bottom. Remove baffle.

Check the operation of the oven burner.

If you have oven selector and temperature selector control knobs: Turn the oven selector knob to “Bake.” Push in and turn temperature control knob

to 3&F. The oven burner should light in 50 to 60 seconds. This delay is normal. The oven safety valve requires a certain time before it will open and allow gas to flow.

f\

lock screw

alr shutter

oriflce

P- oven burner hood

II \- spud

19.

If oven flame needs to be adjusted, locate the air shutter near the center rear of the range. Loosen screw and adjust the air shutter until the proper flame appears. Tighten screw.

20 n Check the operation of the oven broil burner.

If you have oven

selector and temperature selector control knobs: Turn the oven selector knob to “BROIL”. Push in and turn the oven temperature selector knob to “BROIL”.The oven broil burner should light in 50 to 60 seconds. This delay is normal. The oven safety valve requires a certain time before it will open and allow gas to flow.

If you have electronic controls: Push the “BROIL”button.

21 n If the broiler flame needs adjustment:

1.Loosen the lock screw on the air shutter located at the rear of the broil burner.

2.Adjust the air shutter as needed. The flame should have a 1’ long inner cone of

n Replace burner baffle, oven bottom and racks.

your new range, read your Use and Care Guide. Keep Installation Instructions and Guide close to range for easy reference.

L.P. gas conversion

Converting to L.P.gas should be done by a qualified installer.

A n Pressure

gas supply pipe to the pressure regulator located in the bottom rear of range in this

regulator:

Natural

order: shutoff valve, l/2” flare union

adapter, flexible connector, l/2” flare union adapter. Seal all openings in floor or wall wherever range is installed.

11 n Use

gas connections. If flexible connectors are used, be certain connector is not kinked.

12 w Open the shutoff valve in the gas supply line. tiait a few minutes for gas to - move through the gas line.

Fire Hazard

Do Not use an open flame to test for leaks from gas connections.

If you have electronic controls: Push “BAKE” button. ‘1” F will appear in the display. Turn Set knob until 350” appears in the display.

The oven burner should light in 50 to 60 seconds. This delay is normal. The oven safely valve requires a certain time before it will open and allow gas to flow.

Product | Damage | I | |

l Do Not insert any object into the | |||

openings of | the protective | shield that | |

surrounds the ignitor. |

| ||

l Do Not clean | the | area. |

|

Remove storage drawer and oven rack. Remove oven bottom, see Step 17. Regulator is located in lower

Use a wrench to unscrew the cap from the

top by turning counterclockwise. Turn the cap over so the hole end is up. Replace the cap and gasket on the regulator. DO NOT REMOVE THE PRESSURE REGULATOR.

Checking for leaks with a flame may result in a fire or explosion.

13 n Use a brush and liauid deteraent

to test all gas connections for ieaks. BubVbles around connections will indicate a leak. If a leak appears, shut off gas valve controls

and adjust connections. Then check connections again. NEVER TESTFOR GAS LEAKS WITH A MATCH OR OTHER FLAME.

Failure to follow these instructions could result in product damage.

18 n Check the oven burner for proper flame. This flame should have a 1’ long, inner cone of

I

Bn Cooktop burners: Turn the orifice hoods down snug onto pins

(approximately 2 to

u2-l/2 turns). DO NOT OVERTIGHTEN. The I:)I lrner flames will not

Clean all detergent solution from range.

Panel C

yellow tips, blowing or lifting of flame should occur.

be properly adjusted if this conversion is not made.