Gas conversions (from Natural gas to L.P. gas; or from L.P. gas to Natural gas) must be done by a qualified installer.

![]() WARNING

WARNING

Fire Hazard

Shut off gas supply line valve.

Make all conversions before turning gas supply valve back on.

Failure to follow these instructions could result in explosion, fire or other injury.

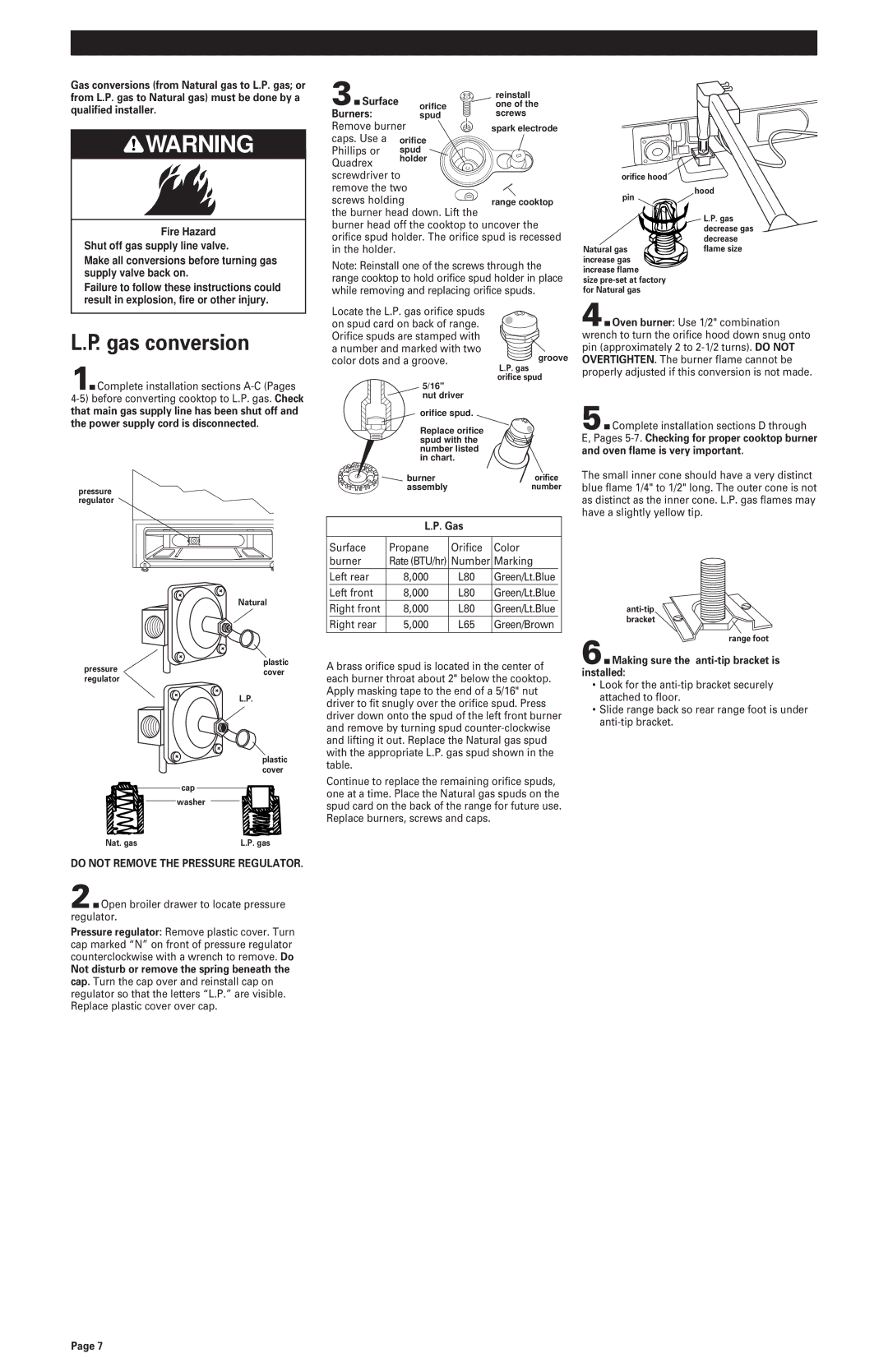

3.Surface |

| reinstall |

orifice | one of the | |

Burners: | spud | screws |

Remove burner | spark electrode | |

caps. Use a | orifice |

|

Phillips or | spud |

|

Quadrex | holder |

|

|

| |

screwdriver to |

| |

remove the two |

| |

screws holding | range cooktop | |

the burner head down. Lift the |

| |

burner head off the cooktop to uncover the orifice spud holder. The orifice spud is recessed in the holder.

Note: Reinstall one of the screws through the range cooktop to hold orifice spud holder in place while removing and replacing orifice spuds.

orifice hood

pin | hood |

| |

| L.P. gas |

| decrease gas |

| decrease |

Natural gas | flame size |

increase gas |

|

increase flame |

|

size |

|

for Natural gas |

|

L.P. gas conversion

1.Complete installation sections A-C (Pages

pressure regulator

Locate the L.P. gas orifice spuds on spud card on back of range. Orifice spuds are stamped with a number and marked with two color dots and a groove.

5/16"

nut driver

orifice spud.

Replace orifice spud with the number listed in chart.

burner assembly

![]() groove

groove

L.P. gas orifice spud

orifice

number

4.Oven burner: Use 1/2" combination wrench to turn the orifice hood down snug onto pin (approximately 2 to

5.Complete installation sections D through E, Pages

The small inner cone should have a very distinct blue flame 1/4" to 1/2" long. The outer cone is not as distinct as the inner cone. L.P. gas flames may have a slightly yellow tip.

Natural

plastic

pressure | cover | |

regulator | ||

| ||

| L.P. |

plastic cover

cap

washer

Nat. gas | L.P. gas |

DO NOT REMOVE THE PRESSURE REGULATOR.

2.Open broiler drawer to locate pressure regulator.

Pressure regulator: Remove plastic cover. Turn cap marked “N” on front of pressure regulator counterclockwise with a wrench to remove. Do

Not disturb or remove the spring beneath the cap. Turn the cap over and reinstall cap on regulator so that the letters “L.P.” are visible. Replace plastic cover over cap.

L.P. Gas

| Surface | Propane | Orifice | Color | |

| burner | Rate (BTU/hr) | Number | Marking |

|

| Left rear | 8,000 | L80 | Green/Lt.Blue |

|

| Left front | 8,000 | L80 | Green/Lt.Blue |

|

| Right front | 8,000 | L80 | Green/Lt.Blue |

|

| Right rear | 5,000 | L65 | Green/Brown | |

|

|

|

|

|

|

A brass orifice spud is located in the center of each burner throat about 2" below the cooktop. Apply masking tape to the end of a 5/16" nut driver to fit snugly over the orifice spud. Press driver down onto the spud of the left front burner and remove by turning spud

Continue to replace the remaining orifice spuds, one at a time. Place the Natural gas spuds on the spud card on the back of the range for future use. Replace burners, screws and caps.

range foot

6.Making sure the

•Look for the

•Slide range back so rear range foot is under

Page 7