Computed kickback angle (CKA) Table

| MODEL | BAR |

| CHAIN P/N | CKA without | ||

| P/N |

| Length | chain brake | |||

|

|

|

| ||||

| 330 | 952044795 |

| 20” | 952051482 | 21_ |

|

| 380 | 952044795 |

| 20” | 952051482 | 21_ |

|

| 330 | 530044833 |

| 22” | 952051483 | 23_ |

|

NOTE: This saw complies with Federal OSHA regulations for commercial logging.

SAFETY NOTICE: Exposure to

vibrations through prolonged use of gasoline powered hand tools could cause blood vessel or nerve damage in the fingers, hands, and joints of people prone to circulation disorders or abnormal swellings. Prolonged use in cold weather has been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of strength, change in skin color or texture, or loss of feeling in the fingers, hands, or joints, discontinue the use of this tool and seek medical attention. An

SPECIAL NOTICE: Your saw is equipped with a temperature limiting muffler and spark arresting screen which meets the requirements of California Codes 4442 and 4443. All U.S. forest land and the states of California, Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington require many internal combustion engines to be equipped with a spark arrestor screen by law. If you operate a chain saw in a state or locale where such regulations exist, you are legally responsible for maintaining the operating condition of these parts. Failure to do so is a violation of the law. Refer to the SERVICE section for maintenance of the Spark Arrestor.

Failure to follow all Safety Rules and Precau- tions can result in serious injury. If situations occur which are not covered in this manual, use care and good judgement. If you need assistance, contact your Authorized Service Dealer.

Protective gloves (not provided) should be worn during assembly.

ATTACHING THE BAR & CHAIN (If not

already attached)

![]() WARNING: If received assembled, repeat all steps to ensure your saw is proper- ly assembled and all fasteners are secure. Always wear gloves when handling the chain. The chain is sharp and can cut you even when it is not moving!

WARNING: If received assembled, repeat all steps to ensure your saw is proper- ly assembled and all fasteners are secure. Always wear gloves when handling the chain. The chain is sharp and can cut you even when it is not moving!

6

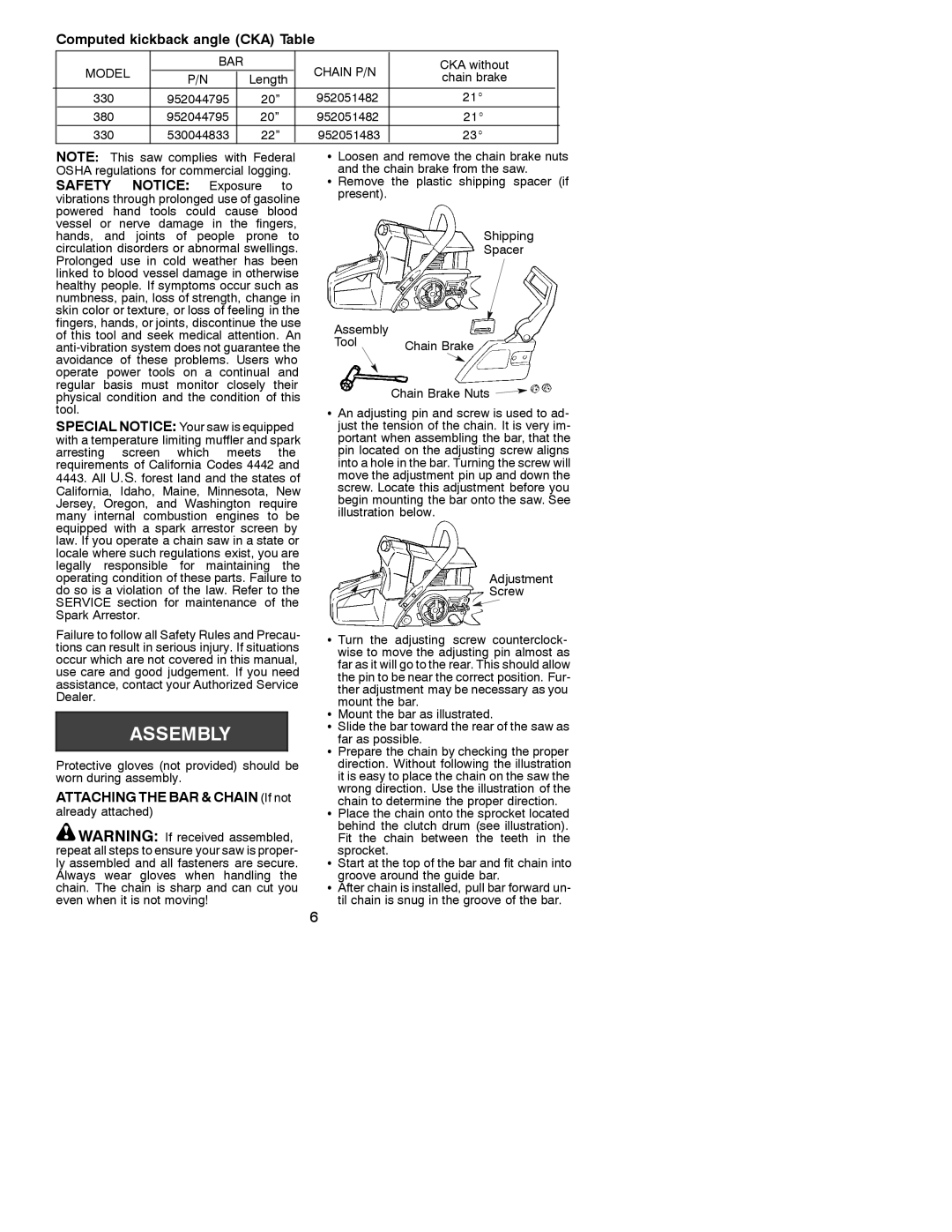

SLoosen and remove the chain brake nuts and the chain brake from the saw.

S Remove the plastic shipping spacer (if present).

Shipping

Spacer

Assembly |

|

Tool | Chain Brake |

|

Chain Brake Nuts ![]()

![]()

![]()

![]()

![]()

![]()

![]()

SAn adjusting pin and screw is used to ad- just the tension of the chain. It is very im- portant when assembling the bar, that the pin located on the adjusting screw aligns into a hole in the bar. Turning the screw will move the adjustment pin up and down the screw. Locate this adjustment before you begin mounting the bar onto the saw. See illustration below.

Adjustment

Screw

S Turn the adjusting screw counterclock- wise to move the adjusting pin almost as far as it will go to the rear. This should allow the pin to be near the correct position. Fur- ther adjustment may be necessary as you mount the bar.

SMount the bar as illustrated.

SSlide the bar toward the rear of the saw as

far as possible.

SPrepare the chain by checking the proper direction. Without following the illustration it is easy to place the chain on the saw the wrong direction. Use the illustration of the

chain to determine the proper direction.

SPlace the chain onto the sprocket located behind the clutch drum (see illustration). Fit the chain between the teeth in the sprocket.

SStart at the top of the bar and fit chain into

groove around the guide bar.

SAfter chain is installed, pull bar forward un- til chain is snug in the groove of the bar.