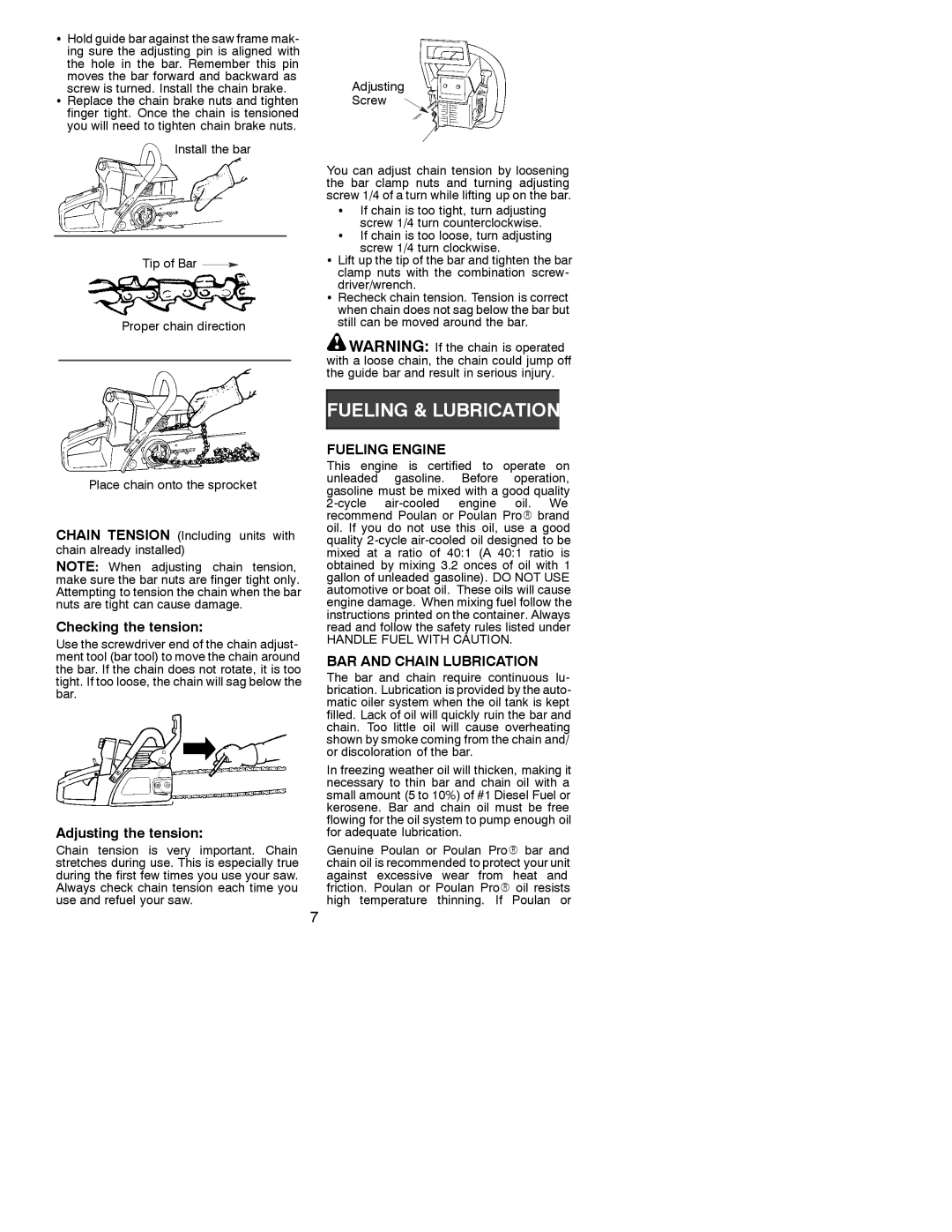

SHold guide bar against the saw frame mak- ing sure the adjusting pin is aligned with the hole in the bar. Remember this pin

moves the bar forward and backward as screw is turned. Install the chain brake.

SReplace the chain brake nuts and tighten finger tight. Once the chain is tensioned you will need to tighten chain brake nuts.

Install the bar

Tip of Bar ![]()

Proper chain direction

Adjusting

Screw

You can adjust chain tension by loosening the bar clamp nuts and turning adjusting screw 1/4 of a turn while lifting up on the bar.

SIf chain is too tight, turn adjusting screw 1/4 turn counterclockwise.

SIf chain is too loose, turn adjusting screw 1/4 turn clockwise.

SLift up the tip of the bar and tighten the bar clamp nuts with the combination screw- driver/wrench.

SRecheck chain tension. Tension is correct when chain does not sag below the bar but still can be moved around the bar.

![]() WARNING: If the chain is operated with a loose chain, the chain could jump off the guide bar and result in serious injury.

WARNING: If the chain is operated with a loose chain, the chain could jump off the guide bar and result in serious injury.

Place chain onto the sprocket

CHAIN TENSION (Including units with chain already installed)

NOTE: When adjusting chain tension, make sure the bar nuts are finger tight only. Attempting to tension the chain when the bar nuts are tight can cause damage.

Checking the tension:

Use the screwdriver end of the chain adjust- ment tool (bar tool) to move the chain around the bar. If the chain does not rotate, it is too tight. If too loose, the chain will sag below the bar.

Adjusting the tension:

Chain tension is very important. Chain stretches during use. This is especially true during the first few times you use your saw. Always check chain tension each time you use and refuel your saw.

7

FUELING ENGINE

This engine is certified to operate on unleaded gasoline. Before operation, gasoline must be mixed with a good quality

HANDLE FUEL WITH CAUTION.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lu- brication. Lubrication is provided by the auto- matic oiler system when the oil tank is kept filled. Lack of oil will quickly ruin the bar and chain. Too little oil will cause overheating shown by smoke coming from the chain and/ or discoloration of the bar.

In freezing weather oil will thicken, making it necessary to thin bar and chain oil with a small amount (5 to 10%) of #1 Diesel Fuel or kerosene. Bar and chain oil must be free flowing for the oil system to pump enough oil for adequate lubrication.

Genuine Poulan or Poulan ProR bar and chain oil is recommended to protect your unit against excessive wear from heat and friction. Poulan or Poulan ProR oil resists high temperature thinning. If Poulan or