SYSTEM WIRING

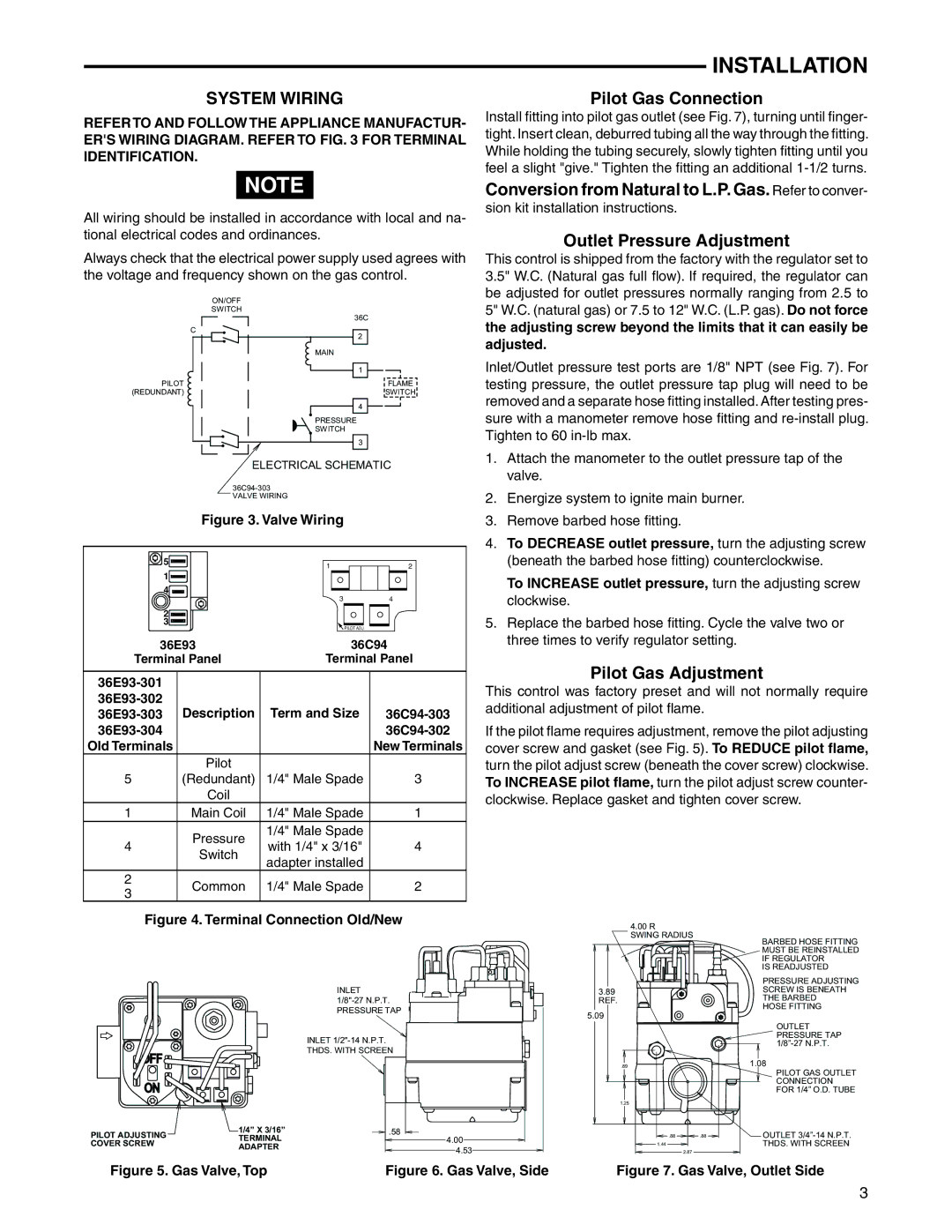

REFERTO AND FOLLOWTHE APPLIANCE MANUFACTUR- ER'S WIRING DIAGRAM. REFER TO FIG. 3 FOR TERMINAL IDENTIFICATION.

NOTE

All wiring should be installed in accordance with local and na- tional electrical codes and ordinances.

Always check that the electrical power supply used agrees with the voltage and frequency shown on the gas control.

ON/OFF

SWITCH

| 36C |

C | 2 |

| |

| MAIN |

INSTALLATION

Pilot Gas Connection

Install fitting into pilot gas outlet (see Fig. 7), turning until finger- tight. Insert clean, deburred tubing all the way through the fitting. While holding the tubing securely, slowly tighten fitting until you feel a slight "give." Tighten the fitting an additional

Conversion from Natural to L.P. Gas. Refer to conver- sion kit installation instructions.

Outlet Pressure Adjustment

This control is shipped from the factory with the regulator set to 3.5" W.C. (Natural gas full flow). If required, the regulator can be adjusted for outlet pressures normally ranging from 2.5 to 5" W.C. (natural gas) or 7.5 to 12" W.C. (L.P. gas). Do not force the adjusting screw beyond the limits that it can easily be adjusted.

| 1 |

PILOT | FLAME |

(REDUNDANT) | SWITCH |

| 4 |

| PRESSURE |

| SWITCH |

| 3 |

ELECTRICAL SCHEMATIC

VALVE WIRING

Figure 3. Valve Wiring

5 | 1 | 2 |

| ||

1 |

|

|

4 |

|

|

3 | 4 |

2 |

|

3 | PILOT ADJ. |

|

36E93 | 36C94 | |||

Terminal Panel | Terminal Panel | |||

|

|

|

| |

|

|

|

| |

| Description | Term and Size |

| |

|

| |||

|

|

|

| |

Old Terminals |

|

| New Terminals | |

| Pilot |

|

| |

5 | (Redundant) | 1/4" Male Spade | 3 | |

| Coil |

|

| |

1 | Main Coil | 1/4" Male Spade | 1 | |

| Pressure | 1/4" Male Spade |

| |

4 | with 1/4" x 3/16" | 4 | ||

Switch | ||||

| adapter installed |

| ||

|

|

| ||

2 | Common | 1/4" Male Spade | 2 | |

3 | ||||

|

|

| ||

Inlet/Outlet pressure test ports are 1/8" NPT (see Fig. 7). For testing pressure, the outlet pressure tap plug will need to be removed and a separate hose fitting installed. After testing pres- sure with a manometer remove hose fitting and

1.Attach the manometer to the outlet pressure tap of the valve.

2.Energize system to ignite main burner.

3.Remove barbed hose fitting.

4.To DECREASE outlet pressure, turn the adjusting screw (beneath the barbed hose fitting) counterclockwise.

To INCREASE outlet pressure, turn the adjusting screw clockwise.

5.Replace the barbed hose fitting. Cycle the valve two or three times to verify regulator setting.

Pilot Gas Adjustment

This control was factory preset and will not normally require additional adjustment of pilot flame.

If the pilot flame requires adjustment, remove the pilot adjusting cover screw and gasket (see Fig. 5). To REDUCE pilot flame, turn the pilot adjust screw (beneath the cover screw) clockwise. To INCREASE pilot flame, turn the pilot adjust screw counter- clockwise. Replace gasket and tighten cover screw.

Figure 4. Terminal Connection Old/New |

| 4.00 R |

|

|

|

| |

|

| SWING RADIUS | BARBED HOSE FITTING |

|

|

| |

|

|

| MUST BE REINSTALLED |

|

|

| IF REGULATOR |

|

|

| IS READJUSTED |

|

|

| PRESSURE ADJUSTING |

INLET | 3.89 |

| SCREW IS BENEATH |

REF. |

| THE BARBED | |

PRESSURE TAP | 5.09 |

| HOSE FITTING |

|

| ||

|

| OUTLET | |

|

|

| |

INLET |

|

| PRESSURE TAP |

|

| ||

THDS. WITH SCREEN |

|

| |

|

|

| |

| .89 |

| 1.08 |

|

|

| PILOT GAS OUTLET |

|

|

| CONNECTION |

|

|

| FOR 1/4” O.D. TUBE |

PILOT ADJUSTING | 1/4” X 3/16” | .58 | |

TERMINAL | 4.00 | ||

COVER SCREW | |||

ADAPTER | 4.53 | ||

| |||

|

|

1.25

.88 | .88 | OUTLET |

1.44 |

| THDS. WITH SCREEN |

| 2.87 |

|

Figure 5. Gas Valve, Top | Figure 6. Gas Valve, Side | Figure 7. Gas Valve, Outlet Side |

3