D500GT specifications

The Wilbur Curtis Company D500GT is a state-of-the-art coffee brewing system that is specifically engineered for high-volume commercial environments. As a leader in the coffee equipment industry, Wilbur Curtis has designed the D500GT with advanced technology and user-friendly features to ensure perfect coffee extraction every time.At the heart of the D500GT is its innovative brewing technology. The unit utilizes a patented brew basket design that allows for optimal coffee-water contact, enhancing flavor extraction and ensuring a rich, consistent brew. This design minimizes channeling, where water passes too quickly through the coffee grounds, leading to weak coffee. The result is a full-bodied flavor profile that coffee lovers appreciate.

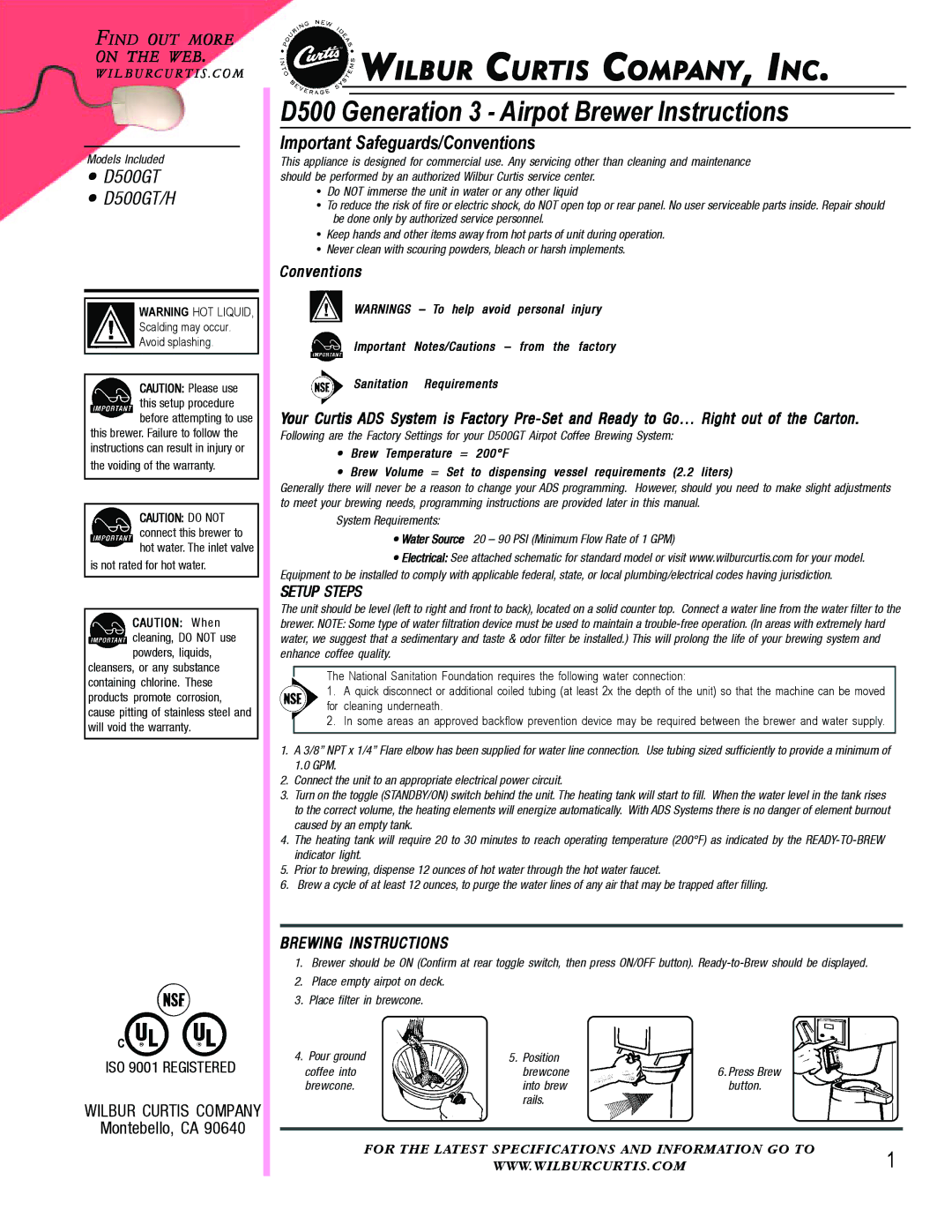

One of the standout features of the D500GT is its adjustable brew temperature control. Users can customize the brewing temperature between 190°F to 205°F, enabling them to manipulate brewing conditions based on the specific coffee bean or blend being used. This level of precision not only helps in extracting the best flavors but also allows for greater versatility in coffee offerings.

The D500GT is designed with a user-friendly digital display that provides instant access to brewing parameters and settings. This intuitive interface allows baristas to easily navigate through functions such as brew time, batch count, and temperature settings. Moreover, the programmable features enable users to have consistent results across multiple brews, which is vital in busy commercial settings.

Another key characteristic of the D500GT is its energy efficiency. The unit is equipped with advanced heating technology that minimizes energy consumption while maintaining optimal performance. This not only reduces operational costs for businesses but also aligns with environmentally friendly practices, making it an excellent choice for eco-conscious establishments.

To enhance durability, the D500GT features a stainless steel construction, making it sturdy enough to withstand the rigors of daily use in high-demand environments. The unit also includes a hot water faucet, adding functionality for tea and other hot beverages.

Overall, the Wilbur Curtis D500GT stands out for its combination of advanced brewing technology, customizable settings, user-friendly interface, and rugged design. These features make it an ideal choice for coffee shops, restaurants, and other establishments looking to provide top-quality coffee consistently. With the D500GT, users can expect not only exceptional coffee brewing capabilities but also a machine built to meet the demands of any busy café.