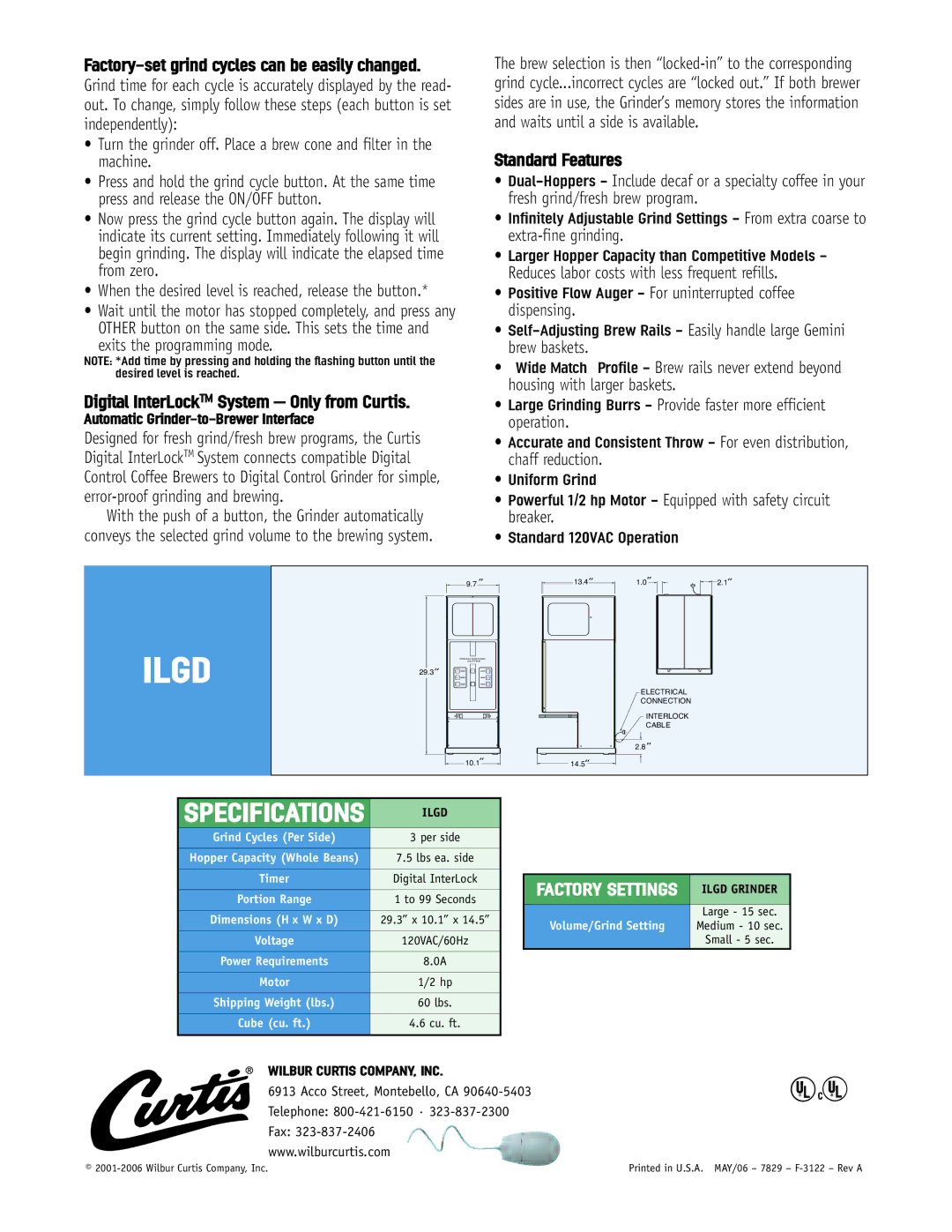

LIGD specifications

Wilbur Curtis Company, renowned for its innovative solutions in the foodservice equipment sector, offers a product line that includes the LIGD model, a standout within their coffee brewing equipment collection. The LIGD, which is designed for high-volume settings like convenience stores, cafes, and catering services, epitomizes both reliability and efficiency.One of the main features of the Wilbur Curtis LIGD is its advanced brewing technology, which employs precision brewing processes to ensure optimal flavor extraction. This model uses a digital control panel that allows operators to easily adjust brewing parameters, such as temperature and brew time, providing total customization to meet diverse customer preferences.

The LIGD also boasts a dual-brew system which enhances versatility. This feature enables users to brew a variety of coffee types, whether it’s a robust dark roast or a lighter blend, catering to different tastes and preferences. Additionally, the unit's high-capacity brewing capability allows it to produce large volumes of coffee swiftly, minimizing wait times during peak hours.

Another critical characteristic of the LIGD is its built-in maintenance alerts and diagnostic capabilities. These features help to simplify the upkeep required for optimal performance, alerting users to necessary cleaning or servicing intervals. This proactive approach reduces downtime and extends the lifespan of the equipment, making it a savvy long-term investment for businesses.

Regarding design, the LIGD is constructed with stainless steel, ensuring durability and ease of cleaning. Its sleek, modern aesthetic allows it to complement various kitchen styles while not compromising on performance. The unit is also designed for ergonomic access, ensuring that staff can operate it efficiently without unnecessary strain.

Ultimately, the Wilbur Curtis Company LIGD encapsulates a combination of technology, user-friendliness, and practicality. From its customizable brewing capabilities to its durable construction and sophisticated features, it serves as an essential asset for any high-volume coffee service environment. As the demand for quality coffee continues to grow, equipment like the LIGD remains at the forefront, meeting the needs of both operators and customers alike.