TCTD-35S, TCO-417, PTTD-3, TCO-308, TCO-421 specifications

Wilbur Curtis Company is a renowned name in the coffee brewing equipment industry, celebrated for its commitment to innovation, quality, and sustainability. The company’s range of coffee brewing systems includes models like the PTTD-3, TCTD-35, TCO-308, TCO-421, and TCO-417. Each of these systems is designed to meet diverse brewing needs, ensuring optimal flavor extraction and user satisfaction.The PTTD-3 is a versatile three-gallon thermal coffee brewer, ideal for high-volume environments such as cafes and restaurants. Its digital programming capabilities allow for precise control over brewing parameters, ensuring consistency in every cup. The PTTD-3 features an advanced brewing technology that includes an adjustable brew time, ensuring that users can fine-tune the extraction process to their liking. The brewer operates with a sleek and user-friendly interface, making it easy for staff to master.

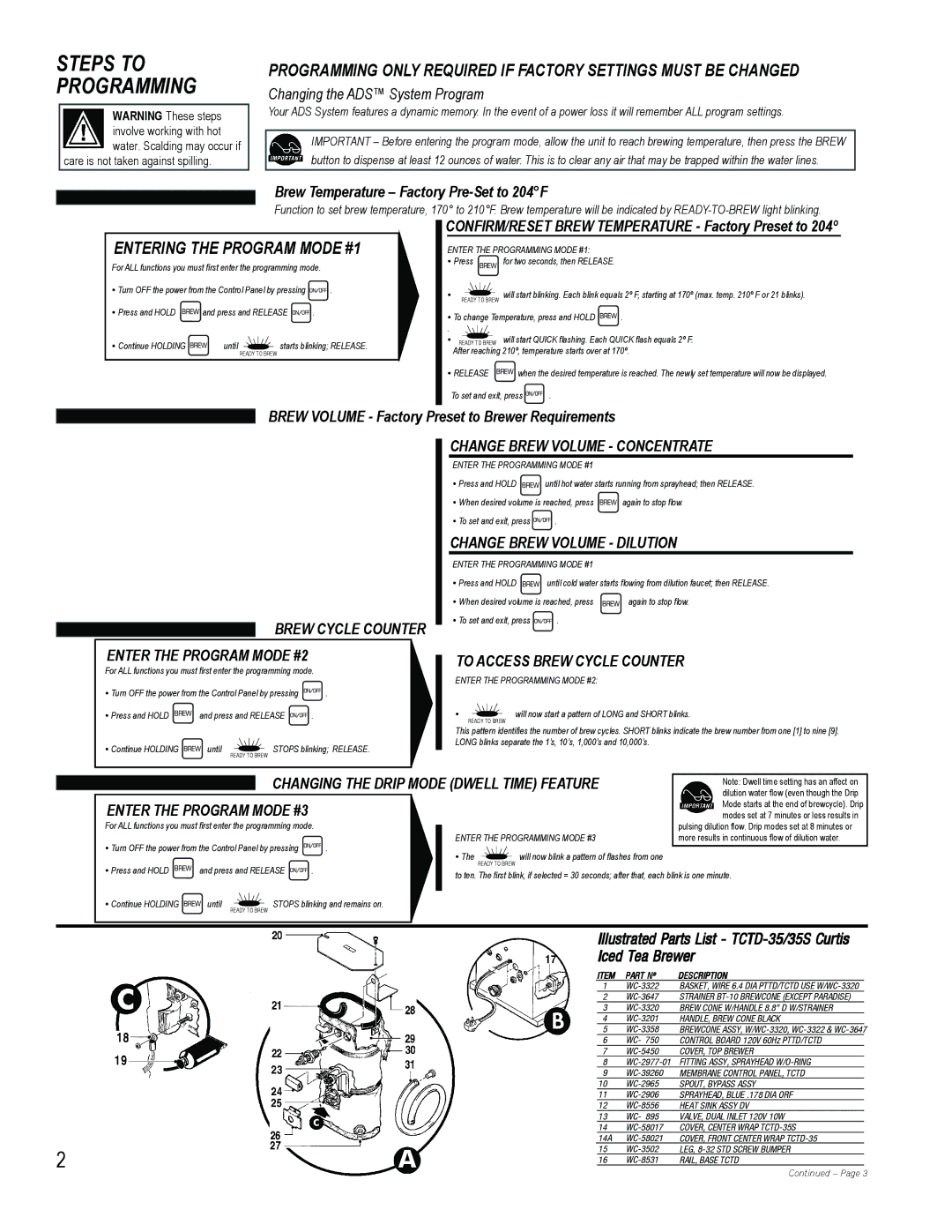

Moving on to the TCTD-35, this model boasts a 3.5-gallon thermal server alongside a high-efficiency brewing system. It is designed with a focus on energy savings, minimizing power consumption while maximizing output quality. The TCTD-35 incorporates a built-in water filtration system that enhances the taste of the coffee, allowing for a rich flavor profile without the interference of impurities. Additionally, the easy-to-clean design ensures that maintenance is straightforward, supporting high-frequency use.

The TCO-308 and TCO-421 are both equipped with state-of-the-art technology for precise temperature control and consistent brew quality. The TCO-308 features a dual coffee brewer setup, allowing for the simultaneous brewing of two different coffee types, making it perfect for diverse clientele. Meanwhile, the TCO-421 stands out with its four-gallon capacity, ideal for businesses experiencing high demand. Both models boast Curtis's patented Smart Brew technology, which helps maintain optimal water temperatures and brewing times for superior extraction.

Last but not least, the TCO-417 is another giant in the Thermal Commercial series, offering a wide range of customization options. It features multi-language programming capabilities and a user-friendly touch interface that facilitates precise calibration. The TCO-417 is built for durability and efficiency, making it a valuable addition to any commercial setting.

In summary, Wilbur Curtis's coffee brewing systems, particularly the PTTD-3, TCTD-35, TCO-308, TCO-421, and TCO-417, exemplify a blend of innovative technology, user-oriented design, and high performance. These brewers are crafted to deliver exceptional quality coffee while supporting the operational efficiency of busy commercial spaces.