10

feed rates, plus a neutral position where the power feed does not operate on the quill.

It is recommended that when doing operations which do not require power feed that the dial be set to the neutral position. This minimizes any wear on the power feed mechanism.

The feed rate selected is indicated by a pair of rivet heads on the edge of the rate setting dial. These values are indicated on the far outer edge of the readout.

Clearly, whenever the indicator rivets are at an "N" position, no feed or "neutral" has been selected.

Any of the three feed rates are available for selection using any of the spindle speeds available. There will be a recommended feed rate for any drilling or boring operation, and this rate must be determined by consulting appropriate machining handbooks or by consulting with your tooling, coolant and work piece suppliers.

Setting depth of cut using the power feed system

There is a mechanism for engaging the power feed and there is also a mechanism (a "trip mecha- nism) which can be set to disengage the power feed when a

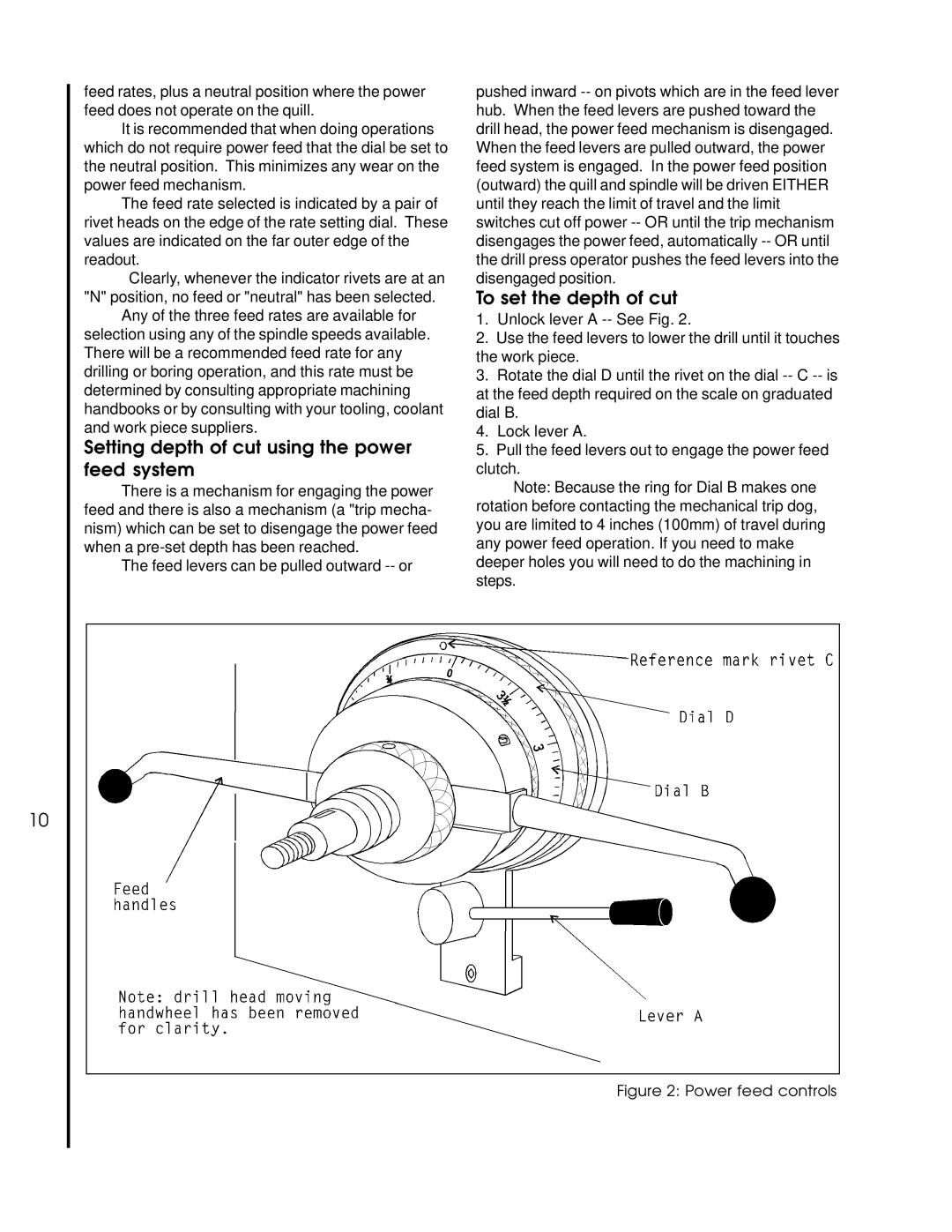

The feed levers can be pulled outward

pushed inward

To set the depth of cut

1.Unlock lever A

2.Use the feed levers to lower the drill until it touches the work piece.

3.Rotate the dial D until the rivet on the dial

4.Lock lever A.

5.Pull the feed levers out to engage the power feed clutch.

Note: Because the ring for Dial B makes one rotation before contacting the mechanical trip dog, you are limited to 4 inches (100mm) of travel during any power feed operation. If you need to make deeper holes you will need to do the machining in steps.