1.Loosen and remove the hex nut and flat washer on the roller shaft with a 24mm wrench.

2.Remove the outer roller.

3.Install a spacer on the shaft and flush against the inner roller as shown in Figure 15.

4.

5.Install the flat washer and hex nut and tighten with wrench.

6.Repeat for the other rollers if needed.

Maintenance

![]() Before performing any maintenance on the Stock Feeder, disconnect it from the electrical supply by pulling out the plug or switching off the breaker. Also make sure the table saw is disconnected from power.

Before performing any maintenance on the Stock Feeder, disconnect it from the electrical supply by pulling out the plug or switching off the breaker. Also make sure the table saw is disconnected from power.

If the power cord is worn, cut, or damaged in any way, have it replaced immediately.

Rollers

The polyurethane rollers should be kept clean of grease, sawdust and other debris. Use a soft cloth with soap and water to wipe down the rollers. DO NOT use a solvent on the rollers.

The rollers can be removed from the Stock Feeder for replacement or maintenance purposes. To remove a roller, loosen and remove the hex nut and flat washer (Figure 15) with a 24mm wrench and pull the roller(s) off the shaft.

Drive Belt Replacement

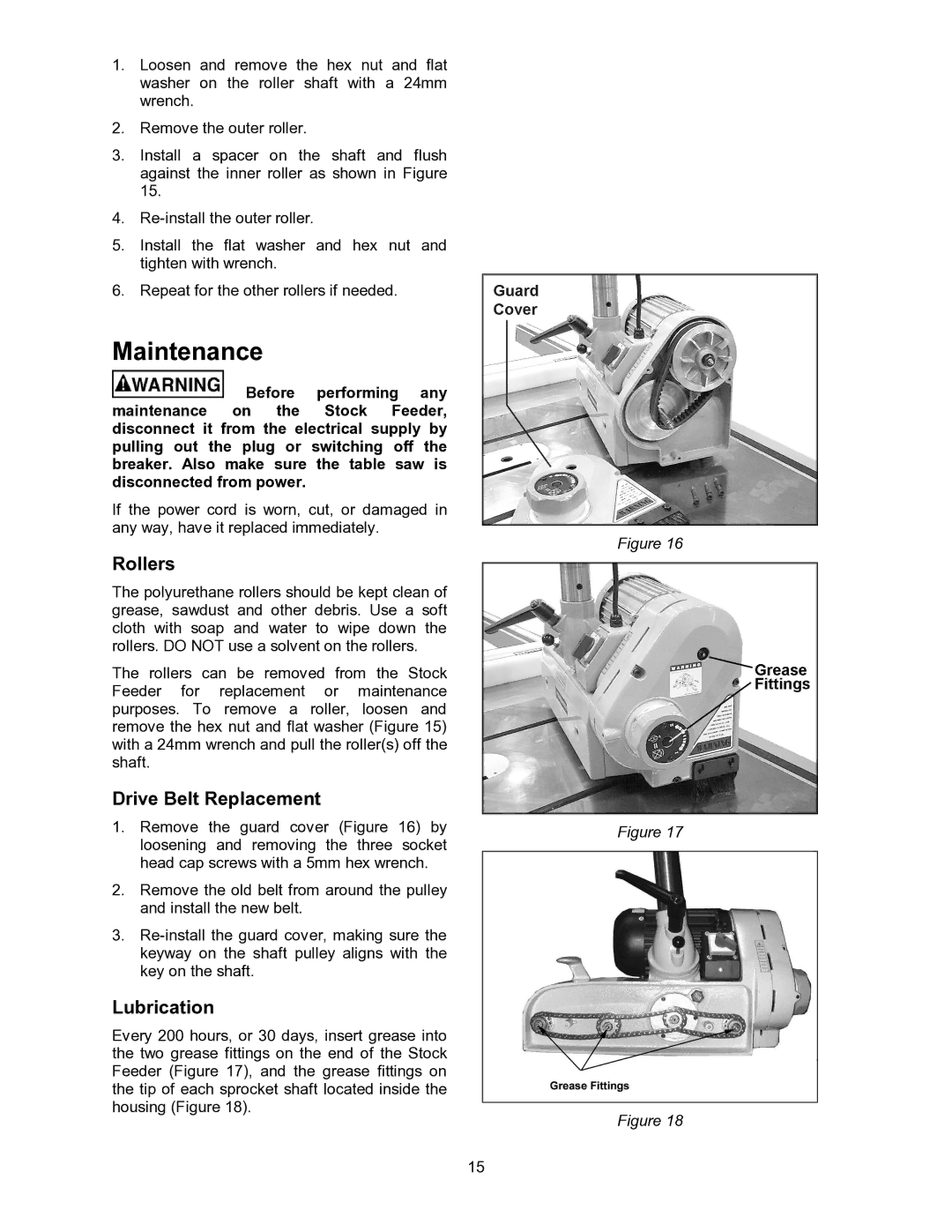

1.Remove the guard cover (Figure 16) by loosening and removing the three socket head cap screws with a 5mm hex wrench.

2.Remove the old belt from around the pulley and install the new belt.

3.

Lubrication

Every 200 hours, or 30 days, insert grease into the two grease fittings on the end of the Stock Feeder (Figure 17), and the grease fittings on the tip of each sprocket shaft located inside the housing (Figure 18).

Figure 16

Figure 17

Figure 18

15