|

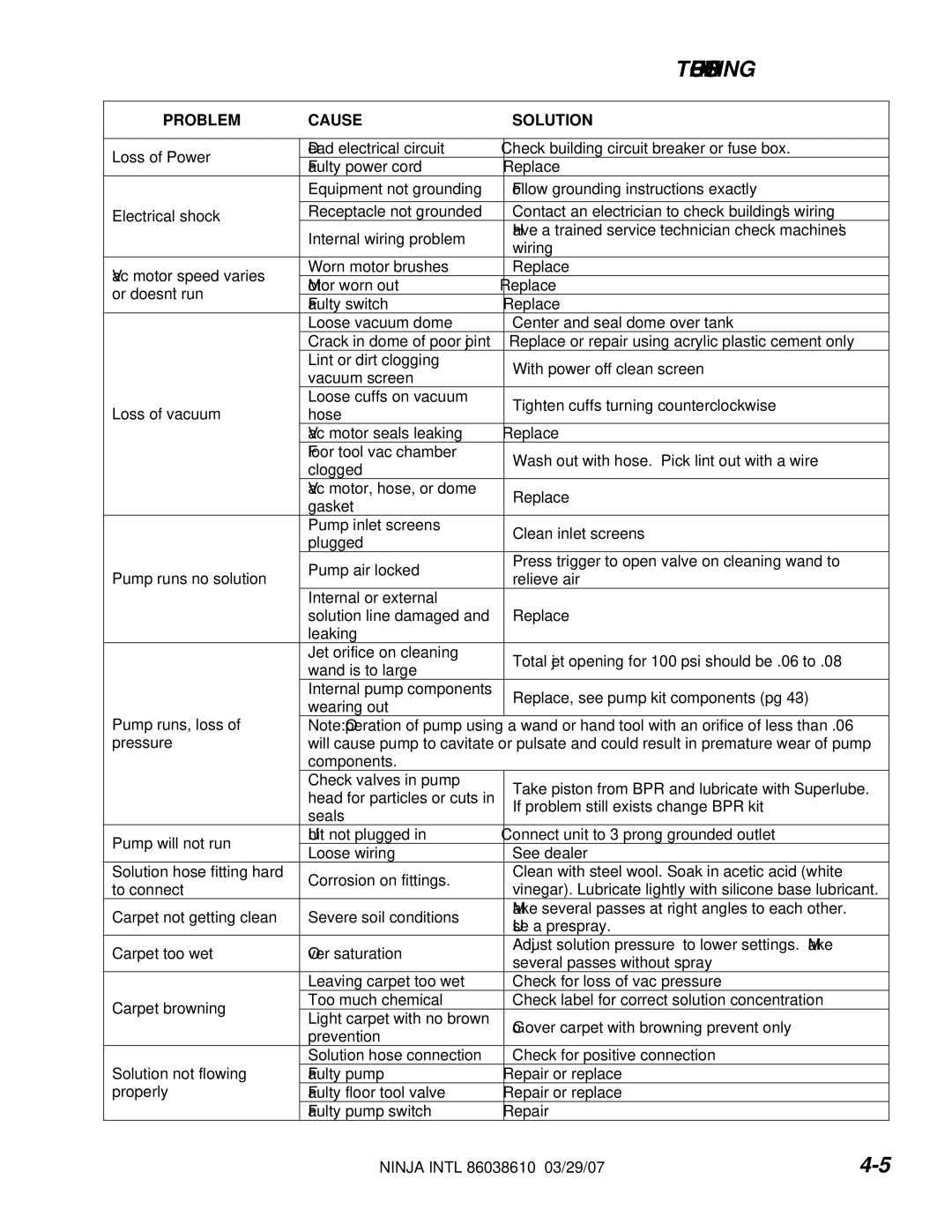

| TROUBLESHOOTING | ||

|

|

|

|

|

PROBLEM | CAUSE | SOLUTION |

|

|

|

|

|

|

|

Loss of Power | Dead electrical circuit | Check building circuit breaker or fuse box. |

|

|

Faulty power cord | Replace |

|

| |

|

|

| ||

| Equipment not grounding | Follow grounding instructions exactly |

|

|

|

|

|

|

|

Electrical shock | Receptacle not grounded | Contact an electrician to check building’s wiring |

|

|

Internal wiring problem | Have a trained service technician check machine’s |

| ||

|

| |||

| wiring |

|

| |

|

|

|

| |

Vac motor speed varies | Worn motor brushes | Replace |

|

|

Motor worn out | Replace |

|

| |

or doesn’t run |

|

| ||

Faulty switch | Replace |

|

| |

|

|

| ||

| Loose vacuum dome | Center and seal dome over tank |

|

|

| Crack in dome of poor joint | Replace or repair using acrylic plastic cement only |

|

|

| Lint or dirt clogging | With power off clean screen |

|

|

| vacuum screen |

|

| |

|

|

|

| |

Loss of vacuum | Loose cuffs on vacuum | Tighten cuffs turning counterclockwise |

|

|

hose |

|

| ||

|

|

| ||

| Vac motor seals leaking | Replace |

|

|

| Floor tool vac chamber | Wash out with hose. Pick lint out with a wire |

|

|

| clogged |

|

| |

|

|

|

| |

| Vac motor, hose, or dome | Replace |

|

|

| gasket |

|

| |

|

|

|

| |

| Pump inlet screens | Clean inlet screens |

|

|

| plugged |

|

| |

|

|

|

| |

Pump runs no solution | Pump air locked | Press trigger to open valve on cleaning wand to |

|

|

relieve air |

|

| ||

|

|

| ||

| Internal or external |

|

|

|

| solution line damaged and | Replace |

|

|

| leaking |

|

|

|

| Jet orifice on cleaning | Total jet opening for 100 psi should be .06 to .08 |

|

|

| wand is to large |

|

| |

|

|

|

| |

| Internal pump components | Replace, see pump kit components (pg |

|

|

| wearing out |

|

| |

Pump runs, loss of |

|

|

| |

Note: Operation of pump using a wand or hand tool with an orifice of less than .06 |

| |||

pressure | will cause pump to cavitate or pulsate and could result in premature wear of pump |

| ||

| components. |

|

|

|

| Check valves in pump | Take piston from BPR and lubricate with Superlube. |

| |

| head for particles or cuts in |

| ||

| If problem still exists change BPR kit |

|

| |

| seals |

|

| |

|

|

|

| |

Pump will not run | Unit not plugged in | Connect unit to 3 prong grounded outlet |

|

|

Loose wiring | See dealer |

|

| |

|

|

| ||

Solution hose fitting hard | Corrosion on fittings. | Clean with steel wool. Soak in acetic acid (white |

|

|

to connect | vinegar). Lubricate lightly with silicone base lubricant. |

| ||

|

| |||

Carpet not getting clean | Severe soil conditions | Make several passes at right angles to each other. |

| |

Use a |

|

| ||

|

|

|

| |

Carpet too wet | Over saturation | Adjust solution pressure to lower settings. Make |

|

|

several passes without spray |

|

| ||

|

|

|

| |

| Leaving carpet too wet | Check for loss of vac pressure |

|

|

Carpet browning | Too much chemical | Check label for correct solution concentration |

|

|

Light carpet with no brown | Go over carpet with browning prevent only |

|

| |

|

|

| ||

| prevention |

|

| |

|

|

|

| |

Solution not flowing | Solution hose connection | Check for positive connection |

|

|

Faulty pump | Repair or replace |

|

| |

properly | Faulty floor tool valve | Repair or replace |

|

|

| Faulty pump switch | Repair |

|

|

| NINJA INTL 86038610 03/29/07 | |||

Page 17

Image 17