3.Keep the battery electrolyte at th$ 4. Check motor brushes. When worn to

-approximately 114 318” replace both brushes.correct level

below bottom of filler tube of each cell. Distilled water should be added, as needed, AFTER charging cycle.

WARNING: Do not allow electrolyte level to drop below the tops of the plates.

![]() ’

’

3. Connect the “DC” charger plug to the connector on the machine. NOTE A safety override switch is activated when the “ D C charge plug is connected. This prevents all panel circuits on the machine from accidentally being switched on during charging cycle.

4.Connect charger “AC” plug to properly Brounded outlet that has correct voltage or the charger.

5.The charger suppled by Wlndsor is totally automatic and shuts off when the batteries are fully charged.

NOTE Refer to the charger manual for detailed charging information.

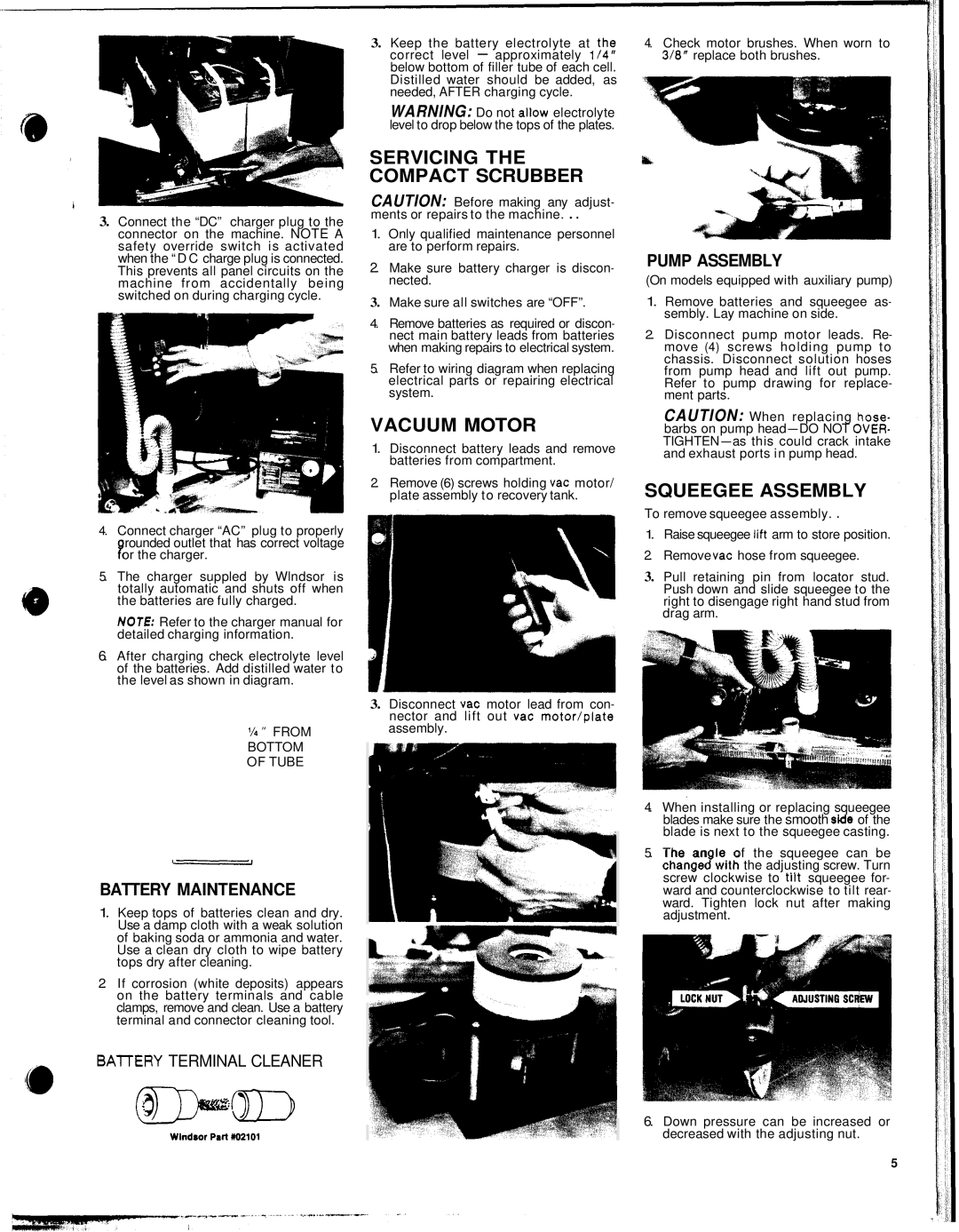

6.After charging check electrolyte level of the batteries. Add distilled water to the level as shown in diagram.

’/4 ” FROM BOTTOM OF TUBE

BATTERY MAINTENANCE

1.Keep tops of batteries clean and dry. Use a damp cloth with a weak solution of baking soda or ammonia and water. Use a clean dry cloth to wipe battery tops dry after cleaning.

2.If corrosion (white deposits) appears on the battery terminals and cable clamps, remove and clean. Use a battery terminal and connector cleaning tool.

BAlTERY TERMINAL CLEANER

SERVICING THE COMPACT SCRUBBER

CAUTION: Before making any adjust- ments or repairs to the machine. . .

1.Only qualified maintenance personnel are to perform repairs.

2.Make sure battery charger is discon- nected.

3.Make sure all switches are “OFF”.

4.Remove batteries as required or discon- nect main battery leads from batteries when making repairs to electrical system.

5.Refer to wiring diagram when replacing electrical parts or repairing electrical system.

VACUUM MOTOR

1.Disconnect battery leads and remove batteries from compartment.

2.Remove (6) screws holding vac motor/ plate assembly to recovery tank.

3.Disconnect vac motor lead from con- nector and lift out vac motor/plate assembly.

PUMP ASSEMBLY

(On models equipped with auxiliary pump)

1.Remove batteries and squeegee as- sembly. Lay machine on side.

2.Disconnect pump motor leads. Re- move (4) screws holding pump to chassis. Disconnect solution hoses from pump head and lift out pump. Refer to pump drawing for replace- ment parts.

CAUTION: When replacing hose- barbs on pump

SQUEEGEE ASSEMBLY

To remove squeegee assembly. .

1.Raise squeegee lift arm to store position.

2.Remove vac hose from squeegee.

3.Pull retaining pin from locator stud. Push down and slide squeegee to the right to disengage right hand stud from drag arm.

4.When installing or replacing squeegee blades make sure the smooth side of the blade is next to the squeegee casting.

5.The an 18 of the squeegee can be changejwith the adjusting screw. Turn screw clockwise to tiit squeegee for- ward and counterclockwise to tilt rear- ward. Tighten lock nut after making adjustment.

Wlndsor Pall M2101

6.Down pressure can be increased or decreased with the adjusting nut.

5