11. VACUUM MOTOR

(Refer to the Vacuum Group in the parts section of manual)

![]()

![]() !

!![]()

Do not use a pressure washer to clean around the vacuum motors. Use tap pressure only. Care must be taken so that water is not directed into vacuum motor air intakes.

CHANGING VACUUM MOTOR

1.Remove side cover.

2.Disconnect electrical connector to the vacuum motor.

3.Loosen clamp and disconnect hose from vacuum intake.

4.Remove vacuum motor mounting bracket bolts, which are located under frame.

5.Remove vacuum motor and mounting bracket assembly.

6.Reverse steps to install

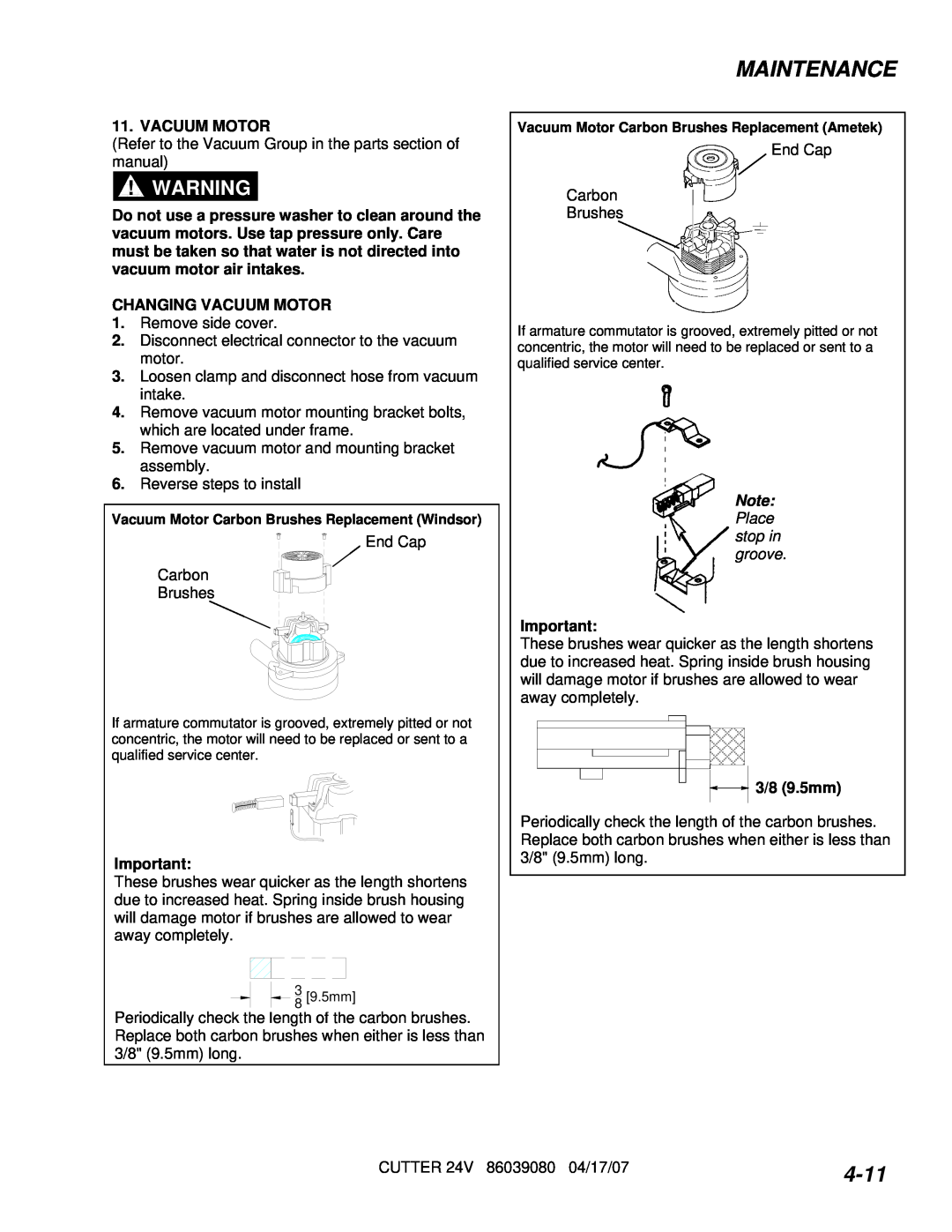

Vacuum Motor Carbon Brushes Replacement (Windsor)

End Cap

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not concentric, the motor will need to be replaced or sent to a qualified service center.

Important:

These brushes wear quicker as the length shortens due to increased heat. Spring inside brush housing will damage motor if brushes are allowed to wear away completely.

![]() 38 [9.5mm]

38 [9.5mm]

Periodically check the length of the carbon brushes. Replace both carbon brushes when either is less than 3/8" (9.5mm) long.

MAINTENANCE

Vacuum Motor Carbon Brushes Replacement (Ametek)

End Cap

Carbon

Brushes

If armature commutator is grooved, extremely pitted or not concentric, the motor will need to be replaced or sent to a qualified service center.

Note: Place stop in groove.

Important:

These brushes wear quicker as the length shortens due to increased heat. Spring inside brush housing will damage motor if brushes are allowed to wear away completely.

![]()

![]() 3/8 (9.5mm)

3/8 (9.5mm)

Periodically check the length of the carbon brushes. Replace both carbon brushes when either is less than 3/8" (9.5mm) long.

CUTTER 24V 86039080 04/17/07 |

|

|