MZ3772K-DFI, MZ3761K-DFI specifications

The Woods Equipment MZ3761K-DFI and MZ3772K-DFI are the latest additions to the esteemed line of compact tractors, providing advanced technology and robust performance for both commercial and agricultural applications. These models are designed with a keen focus on user efficiency and ease of operation, making them suitable for a wide range of tasks such as landscaping, mowing, and general property maintenance.One of the standout features of both the MZ3761K-DFI and MZ3772K-DFI is their powerful diesel engine. These tractors are equipped with Direct Fuel Injection (DFI) systems that ensure optimal fuel efficiency and reduced emissions, contributing to a more sustainable operational footprint. The engines also offer a seamless power delivery that enhances performance during challenging tasks, whether navigating rugged terrain or handling heavy attachments.

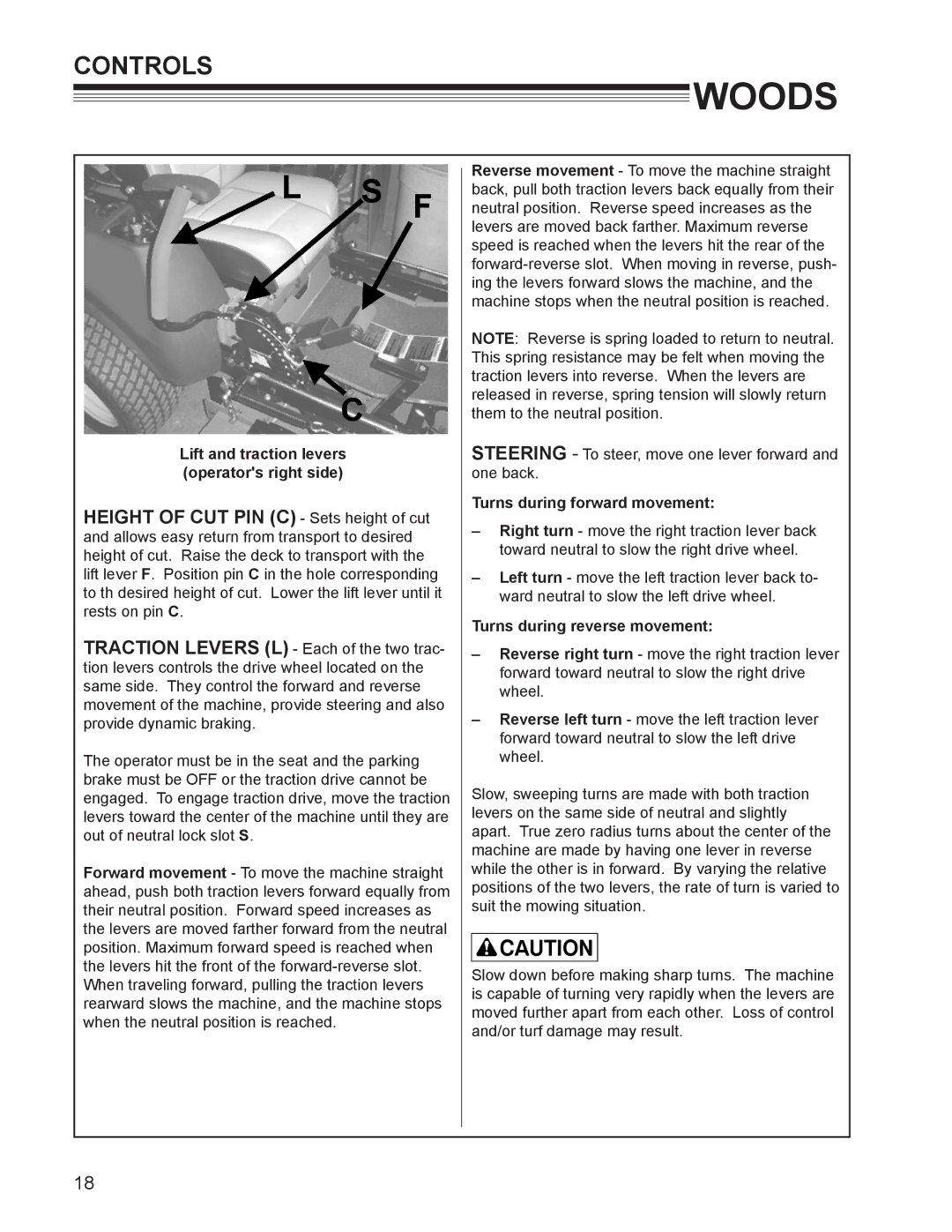

The MZ series features a user-friendly hydrostatic transmission that provides smooth operation and allows operators to effortlessly manage speed and direction with minimal effort. This feature is particularly beneficial for maneuvering in tight spaces or when executing precise tasks, making it a favorite among operators who value comfort and efficiency.

Both models come equipped with advanced hydraulic systems that enable enhanced lifting capabilities. This is particularly useful for tasks such as loading and moving materials. The hydraulic lift arms can accommodate a variety of attachments, from loaders to brush cutters, offering versatility to handle diverse applications.

These tractors are designed with operator comfort in mind, featuring ergonomically designed controls and spacious operator platforms. The adjustable seats ensure long hours of work can be performed without discomfort, while the visibility from the operator's seat allows for safe maneuvering around job sites.

In terms of build quality, the MZ3761K-DFI and MZ3772K-DFI boast heavy-duty construction that translates to durability and reliability. With robust frames and high-quality components, these tractors are built to endure rigorous use and provide dependable service over time.

Moreover, both models integrate advanced safety features, including roll-over protective structures (ROPS) and safety interlocks, ensuring that operators can work with confidence.

In summary, the Woods Equipment MZ3761K-DFI and MZ3772K-DFI are truly versatile compact tractors that deliver exceptional power, efficiency, and operator comfort. Their innovative technologies and robust build make them a worthy investment for professionals seeking reliable performance in their daily operations.