-14-

M1014 7" x 12" Metal Cutting Bandsaw

SET UP

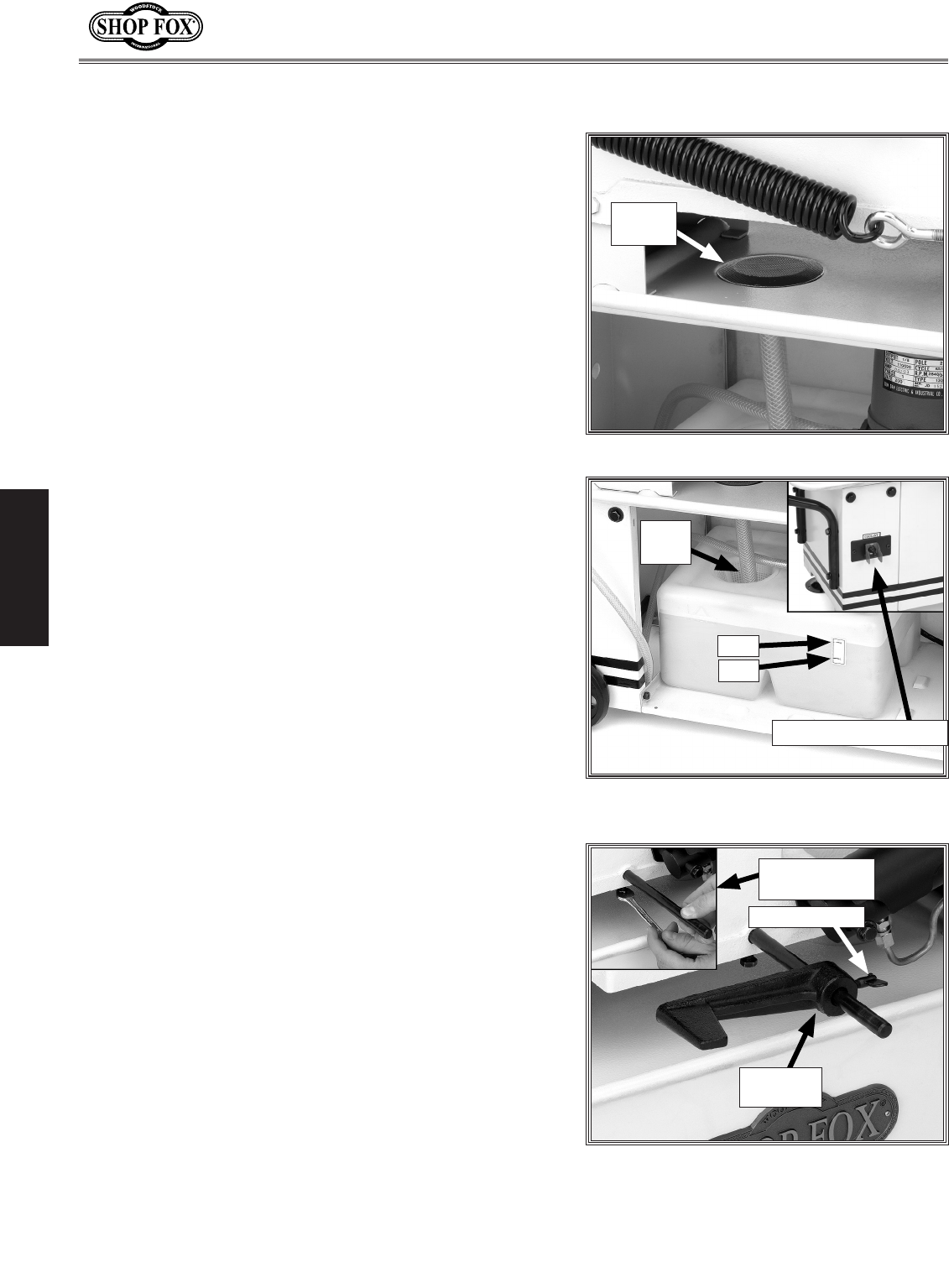

Cutting Fluid SystemFigure 15. Installed drain screen.

Figure 16. Correctly filled tank ready to

be pumped.

Figure 17. Installing the cast iron stop.

This bandsaw has a built-in cutting fluid system that

prolongs the life of your bandsaw blades and produces

smoother cuts at a lower temperature. Refer to Cutting

Fluid on Page 26 for fluid choice and safety precautions.

To set up the cutting fluid system, do these steps:

1. Place the filter screen dome-side up as shown in

Figure 15 in the bandsaw catch pan.

2. Inspect and remove any foreign material that may

have fallen inside the reservoir during shipping.

3. Make sure the drain tube points toward the reservoir

intake screen, and that all tube connections are

tight and will not leak (see Figure 16).

4. Make sure the waterproof rubber switch boot is

installed on the pump ON/OFF toggle switch (Figure

16), and that the toggle switch is in the down

position.

Note: DO NOT plug in the bandsaw at this time

to prime the pump. Priming will be done in the

Operations section.

5. Fill the reservoir with 2-1/2 gallons of your chosen

cutting fluid solution.

NOTICE: NEVER operate the pump with the reservoir

below the low mark (Figure 16), or the pump

can be destroyed!

Cast Iron StopThe cast iron stop allows you to repeat many cuts at the

same length.

To install the cast iron stop, do these steps:

1. Insert the stop rod approximately 3/4" into the saw

until the end of the rod is just flush with the inside

casting surface (see Figure 17).

2. Use a 12mm wrench, and tighten the hex bolt (see

Figure 17).

3. Slide the cast iron stop onto the stop rod and

tighten the thumb screw.

Filter

Screen

Pump Toggle Switch

Drain

Tube

High

Low

Stop Rod

and Hex Bolt

Cast Iron

Stop

Thumbscrew