XIV. TROUBLESHOOTING

A. TEAR-OUT

When cutting across the grain of the wood, tear- out or splintering may occur when the router bit exits the workpiece. To prevent

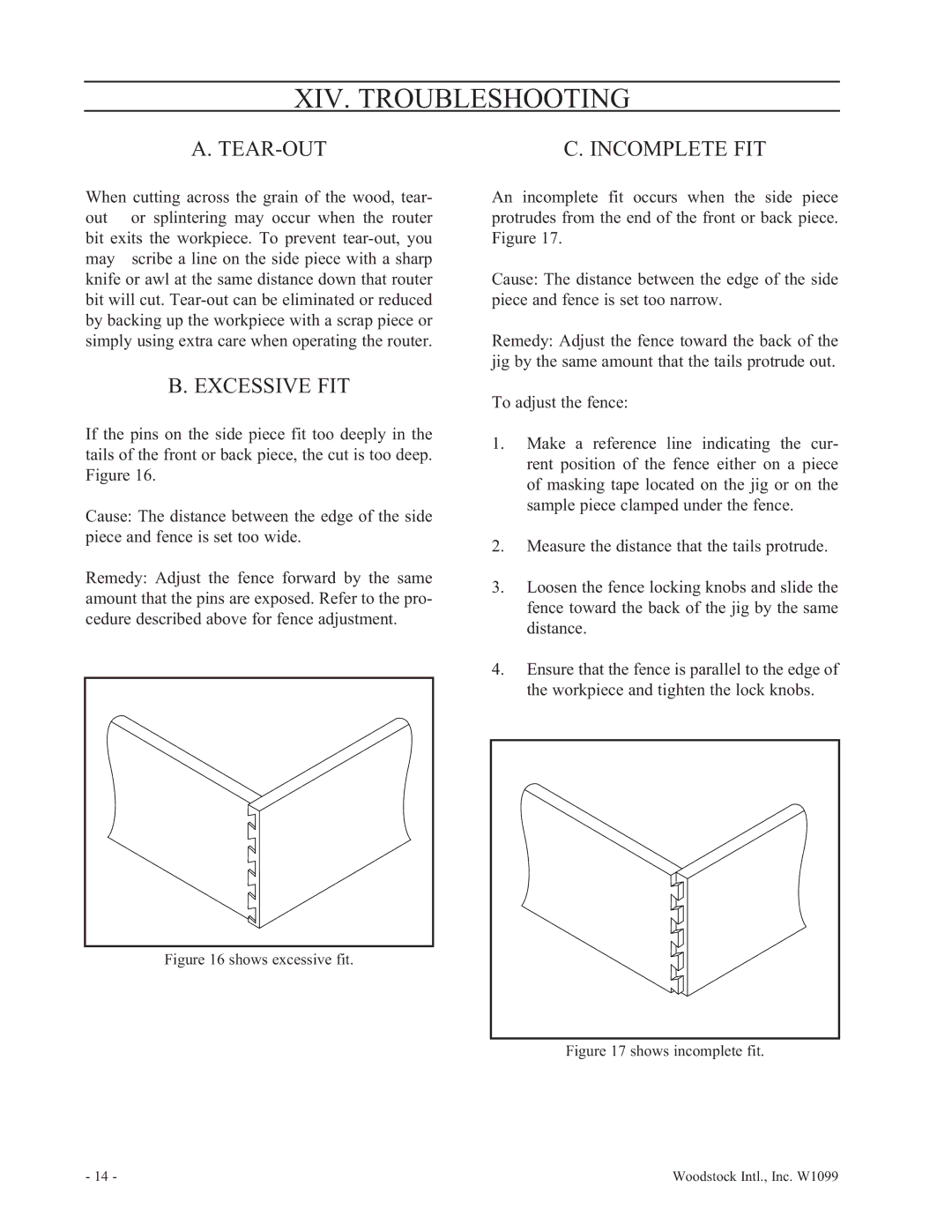

B. EXCESSIVE FIT

If the pins on the side piece fit too deeply in the tails of the front or back piece, the cut is too deep. Figure 16.

Cause: The distance between the edge of the side piece and fence is set too wide.

Remedy: Adjust the fence forward by the same amount that the pins are exposed. Refer to the pro- cedure described above for fence adjustment.

Figure 16 shows excessive fit.

C. INCOMPLETE FIT

An incomplete fit occurs when the side piece protrudes from the end of the front or back piece. Figure 17.

Cause: The distance between the edge of the side piece and fence is set too narrow.

Remedy: Adjust the fence toward the back of the jig by the same amount that the tails protrude out.

To adjust the fence:

1.Make a reference line indicating the cur- rent position of the fence either on a piece of masking tape located on the jig or on the sample piece clamped under the fence.

2.Measure the distance that the tails protrude.

3.Loosen the fence locking knobs and slide the fence toward the back of the jig by the same distance.

4.Ensure that the fence is parallel to the edge of the workpiece and tighten the lock knobs.

Figure 17 shows incomplete fit.

- 14 - | Woodstock Intl., Inc. W1099 |