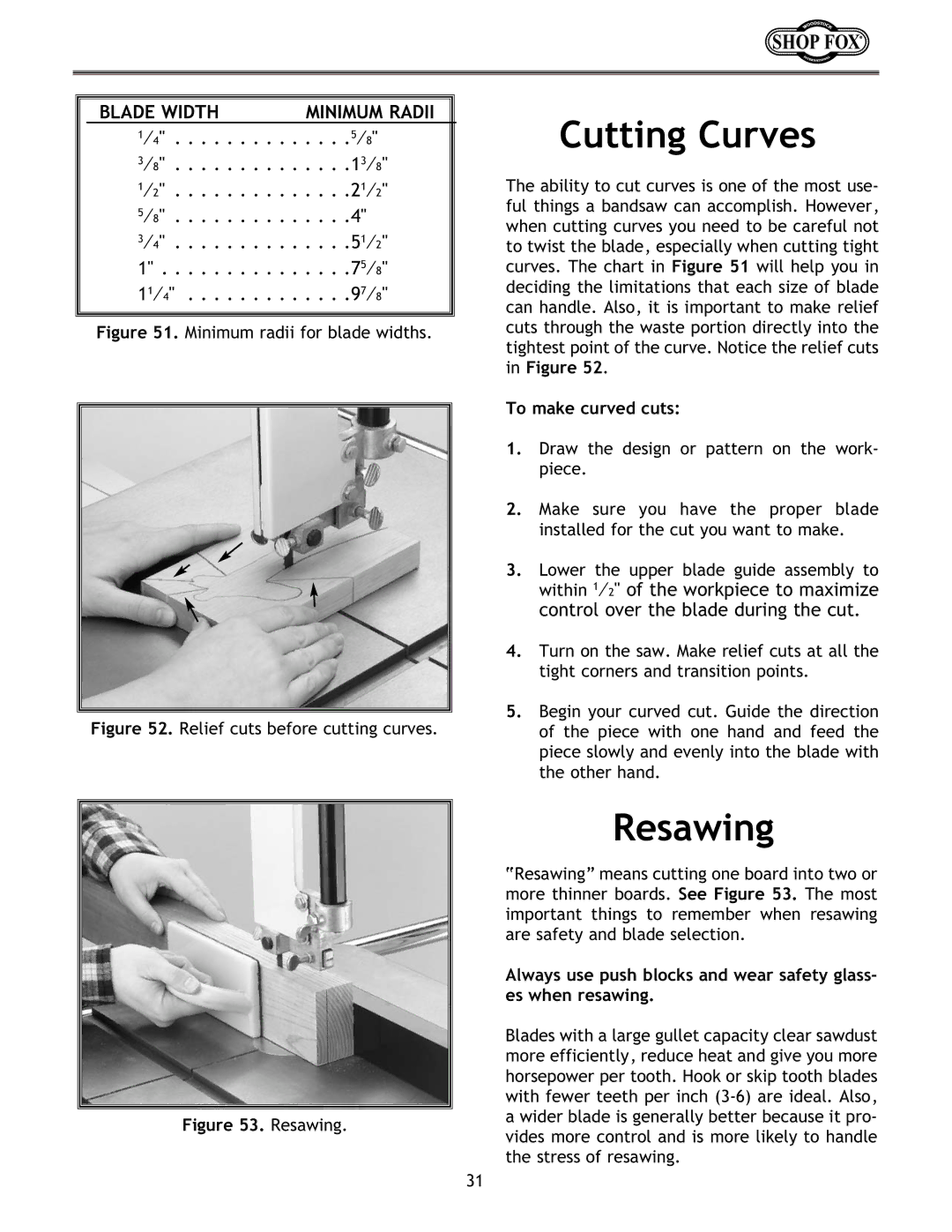

BLADE WIDTH | MINIMUM RADII |

1⁄4" . . . . . . . . . . . . . .5⁄8"

3⁄8" . . . . . . . . . . . . . .13⁄8" 1⁄2" . . . . . . . . . . . . . .21⁄2" 5⁄8" . . . . . . . . . . . . . .4"

3⁄4" . . . . . . . . . . . . . .51⁄2" 1" . . . . . . . . . . . . . . .75⁄8" 11⁄4" . . . . . . . . . . . . .97⁄8"

Figure 51. Minimum radii for blade widths.

Figure 52. Relief cuts before cutting curves.

Figure 53. Resawing.

Cutting Curves

The ability to cut curves is one of the most use- ful things a bandsaw can accomplish. However, when cutting curves you need to be careful not to twist the blade, especially when cutting tight curves. The chart in Figure 51 will help you in deciding the limitations that each size of blade can handle. Also, it is important to make relief cuts through the waste portion directly into the tightest point of the curve. Notice the relief cuts in Figure 52.

To make curved cuts:

1.Draw the design or pattern on the work- piece.

2.Make sure you have the proper blade installed for the cut you want to make.

3.Lower the upper blade guide assembly to within 1⁄2" of the workpiece to maximize control over the blade during the cut.

4.Turn on the saw. Make relief cuts at all the tight corners and transition points.

5.Begin your curved cut. Guide the direction of the piece with one hand and feed the piece slowly and evenly into the blade with the other hand.

Resawing

“Resawing” means cutting one board into two or more thinner boards. See Figure 53. The most important things to remember when resawing are safety and blade selection.

Always use push blocks and wear safety glass- es when resawing.

Blades with a large gullet capacity clear sawdust more efficiently, reduce heat and give you more horsepower per tooth. Hook or skip tooth blades with fewer teeth per inch

31