Model W1821 (For Machines Mfg. Since 3/10)

OPERATIONS

Routing Small Stock

Feeding small stock past the router bit is always dangerous. If you must route small stock, use a zero- clearance fence. This will provide greater protection for the operator, better workpiece support, and reduced tear out on narrow or fragile stock.

To make a zero-clearance fence, do these steps:

1.DISCONNECT ROUTER FROM POWER!

2.Remove the fence boards from the fence assembly.

3.Select a piece of straight and smooth stock that is the same height and thickness as the fence boards and approximately 24" long.

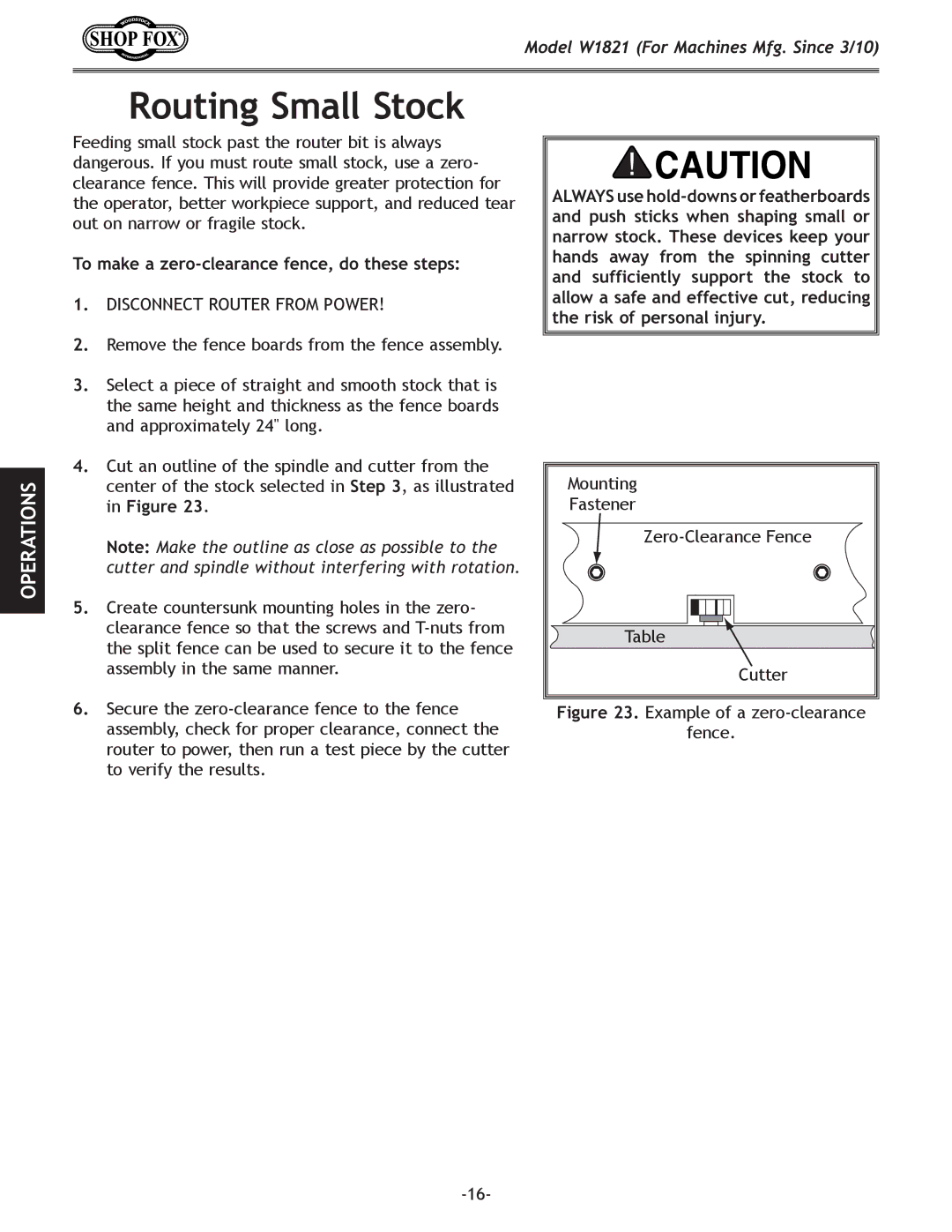

4.Cut an outline of the spindle and cutter from the center of the stock selected in Step 3, as illustrated in Figure 23.

Note: Make the outline as close as possible to the cutter and spindle without interfering with rotation.

5.Create countersunk mounting holes in the zero- clearance fence so that the screws and

6.Secure the

ALWAYS use

Mounting |

Fastener |

Table |

Cutter |