LINE SIZING

TABLE 4

1Based on

2These friction losses do not include any allowance for fittings.

3The total pressure drop of the liquid line for both friction and vertical rise must not exceed 40 PSI. If the pressure drop exceeds 40 PSI, the liquid refrigerant could flash before it reaches the expansion valve. This flashing will not only cause erratic valve operation and poor system performance, but could also damage the expansion valve.

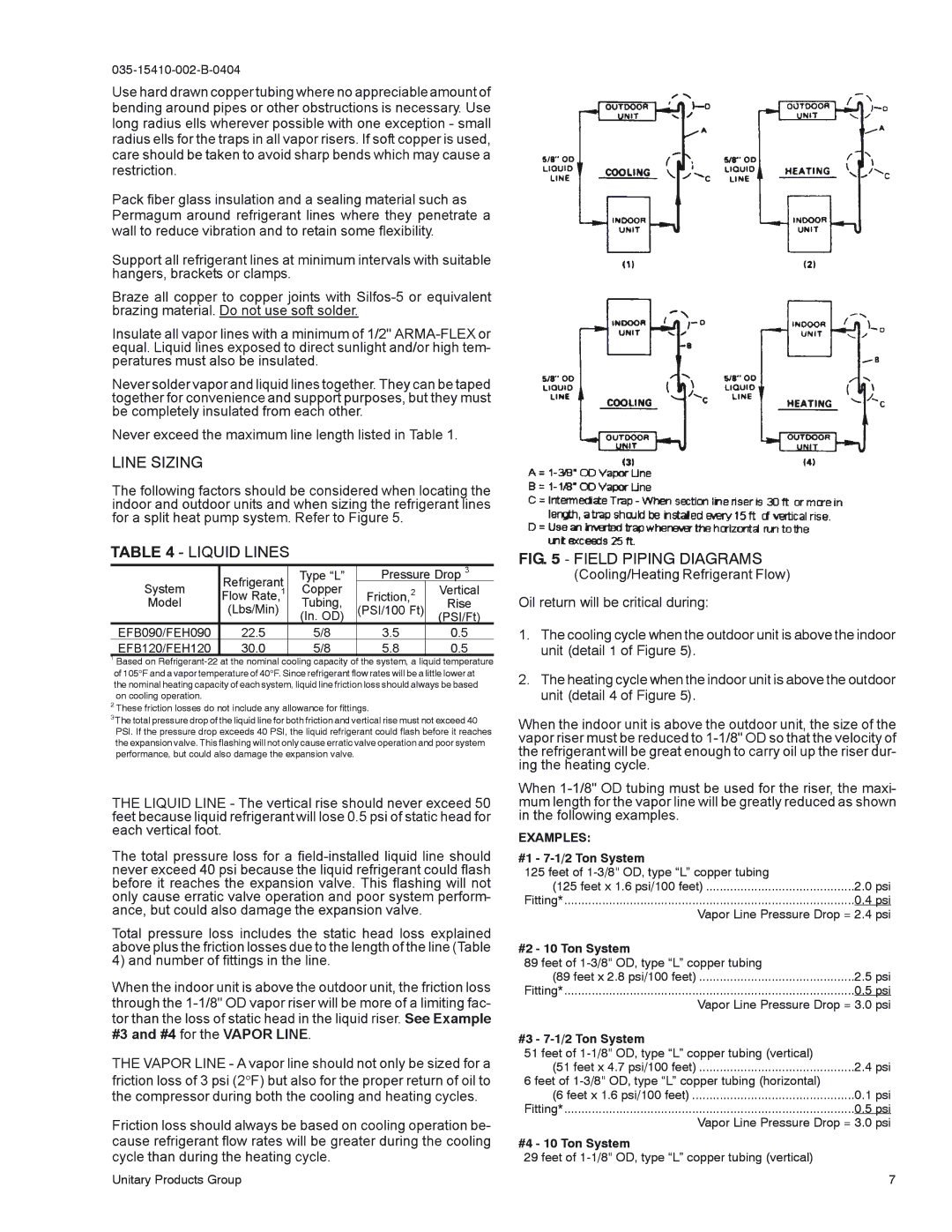

FIG. 5 - FIELD PIPING DIAGRAMS

Oil return will be critical during:

The cooling cycle when the outdoor unit is above the indoor unit (detail 1 of Figure 5).

The heating cycle when the indoor unit is above the outdoor unit (detail 4 of Figure 5).

EXAMPLES: |

|

#1 - |

|

125 feet of |

|

(125 feet x 1.6 psi/100 feet) | 2.0 psi |

Fitting* | 0.4 psi |

Vapor Line Pressure Drop = 2.4 psi | |

#2 - 10 Ton System |

|

89 feet of | |

(89 feet x 2.8 psi/100 feet) | .............................................2.5 psi |

Fitting* | 0.5 psi |

| Vapor Line Pressure Drop = 3.0 psi |

| #3 - |

|

| 51 feet of |

|

° | (51 feet x 4.7 psi/100 feet) | 2.4 psi |

6 feet of |

| |

| (6 feet x 1.6 psi/100 feet) | 0.1 psi |

| Fitting* | 0.5 psi |

| Vapor Line Pressure Drop = 3.0 psi | |

| #4 - 10 Ton System |

| 29 feet of |

Unitary Products Group | 7 |