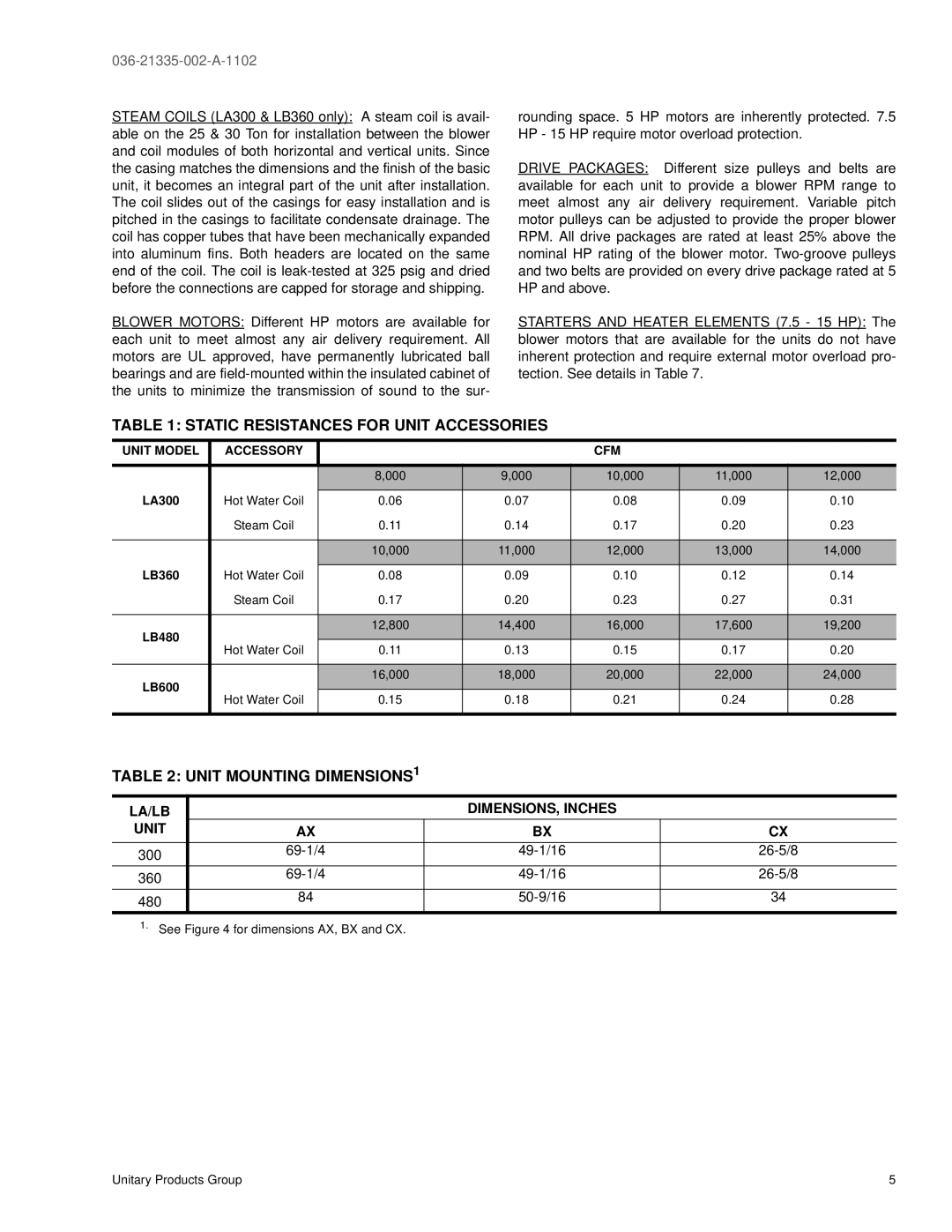

480, 600, LA300, LB360 specifications

York LB360, LA300, 600, and 480 are part of the innovative line of air conditioning and heating solutions developed by Johnson Controls under the York brand. These models are specifically designed to cater to the diverse needs of commercial and industrial applications, delivering high performance, energy efficiency, and reliability.The York LB360 is an advanced rooftop unit that combines robust construction with cutting-edge technology. One of its main features is its remarkably high-efficiency variable-speed compressor, which allows for precise temperature control while minimizing energy consumption. This model is ideal for medium to large commercial spaces, as it offers flexible configurations and a wide range of cooling capacities, ensuring optimal performance in various climates.

The LA300, on the other hand, is highly regarded for its incredibly quiet operation and compact design. It features advanced sound-dampening technologies that significantly reduce noise levels, making it a suitable choice for environments where low sound emissions are critical, such as schools, hospitals, and offices. The LA300 also integrates smart controls that allow for remote monitoring and management, enhancing overall operational efficiency.

The York 600 series is engineered with durability and serviceability in mind. Its modular design simplifies maintenance, allowing technicians to quickly access critical components. This series includes features like integrated economizers and variable frequency drives, which boost energy efficiency by optimizing airflow and compressor operation based on real-time conditions. The 600 series units are particularly advantageous in large facilities requiring reliable year-round climate control.

Finally, the York 480 model emphasizes advanced control capabilities. It uses cutting-edge microprocessor technology to enable sophisticated diagnostics and performance tracking, thereby reducing downtime and maintenance costs. With an option for web-based control, users can conveniently adjust settings and monitor the system from any location. This model is perfect for facility managers looking for a high level of control over their heating and cooling systems.

In summary, York's LB360, LA300, 600, and 480 models exemplify the brand's commitment to innovation, efficiency, and flexibility in climate control solutions. These units cater to a wide spectrum of commercial and industrial needs, ensuring comfort while helping to reduce energy expenses.