BC2604DL / BC2604DW

9. Maintenance

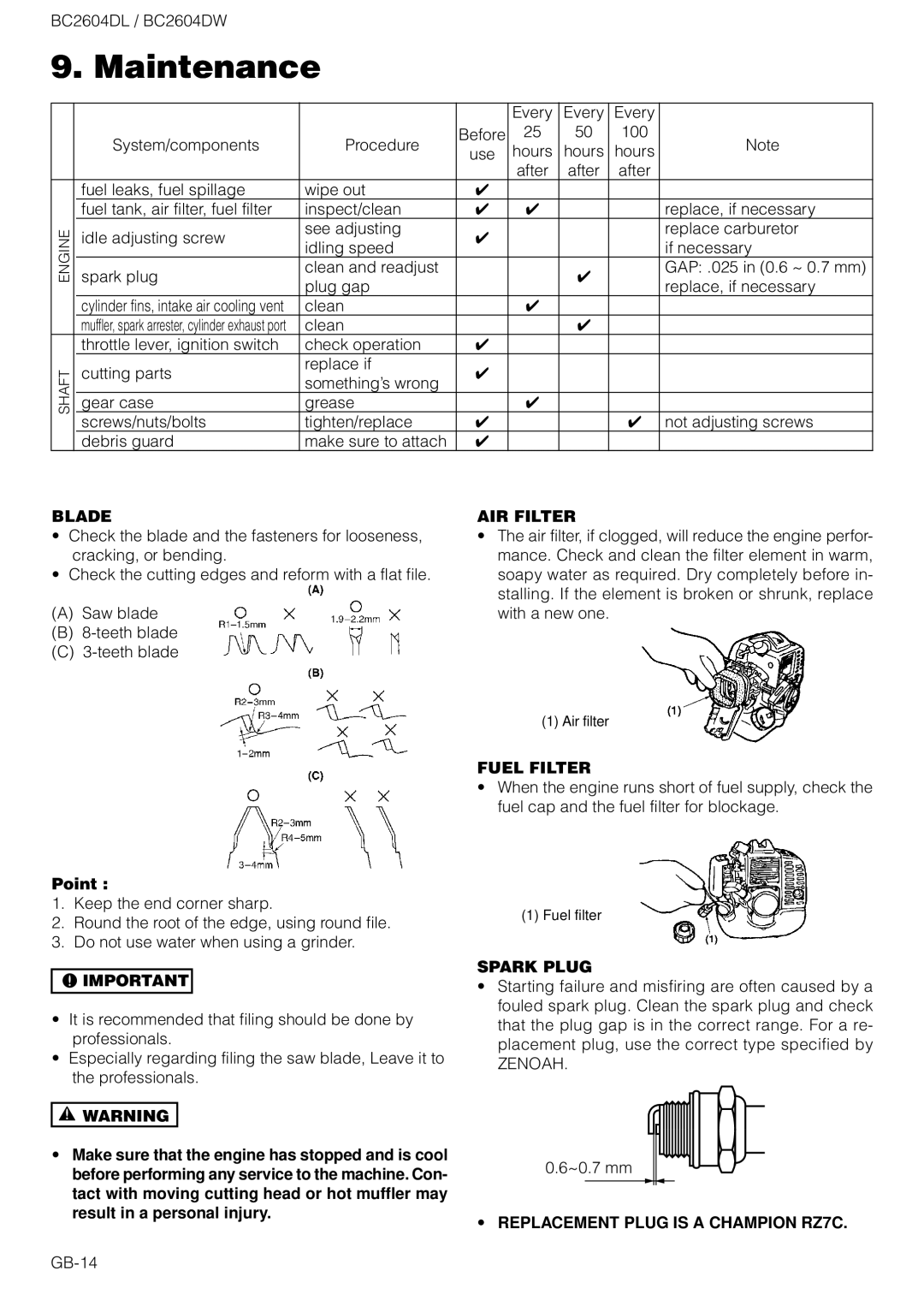

|

|

|

| Every | Every | Every |

|

| System/components | Procedure | Before | 25 | 50 | 100 | Note |

| use | hours | hours | hours | |||

|

|

|

| ||||

|

|

|

| after | after | after |

|

| fuel leaks, fuel spillage | wipe out | ✔ |

|

|

|

|

| fuel tank, air filter, fuel filter | inspect/clean | ✔ | ✔ |

|

| replace, if necessary |

ENGINE | spark plug | see adjusting | ✔ |

| ✔ |

| replace carburetor |

| idle adjusting screw | idling speed |

|

|

| if necessary | |

|

|

|

|

|

| ||

|

| clean and readjust |

|

|

|

| GAP: .025 in (0.6 ~ 0.7 mm) |

|

| plug gap |

|

|

|

| replace, if necessary |

| cylinder fins, intake air cooling vent | clean |

| ✔ |

|

|

|

| muffler, spark arrester, cylinder exhaust port | clean |

|

| ✔ |

|

|

| throttle lever, ignition switch | check operation | ✔ |

|

|

|

|

SHAFT | cutting parts | replace if | ✔ |

|

|

|

|

something’s wrong |

|

|

|

| |||

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

| gear case | grease |

| ✔ |

|

|

|

| screws/nuts/bolts | tighten/replace | ✔ |

|

| ✔ | not adjusting screws |

| debris guard | make sure to attach | ✔ |

|

|

|

|

BLADE

•Check the blade and the fasteners for looseness, cracking, or bending.

•Check the cutting edges and reform with a flat file.

(A)Saw blade

(B)

(C)

AIR FILTER

•The air filter, if clogged, will reduce the engine perfor- mance. Check and clean the filter element in warm, soapy water as required. Dry completely before in- stalling. If the element is broken or shrunk, replace with a new one.

Point :

1.Keep the end corner sharp.

2.Round the root of the edge, using round file.

3.Do not use water when using a grinder.

![]() IMPORTANT

IMPORTANT

•It is recommended that filing should be done by professionals.

•Especially regarding filing the saw blade, Leave it to the professionals.

![]()

![]() WARNING

WARNING

•Make sure that the engine has stopped and is cool before performing any service to the machine. Con- tact with moving cutting head or hot muffler may result in a personal injury.

(1) Air filter

FUEL FILTER

•When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage.

(1) Fuel filter

SPARK PLUG

•Starting failure and misfiring are often caused by a fouled spark plug. Clean the spark plug and check that the plug gap is in the correct range. For a re- placement plug, use the correct type specified by

ZENOAH.

0.6~0.7 mm