2.Rest the unit on a flat, firm place. Keep the cutting head off the ground and clear of surrounding objects, as it will start rotating upon starting of the engine.

3.Open the fuel tank cock.

(1)Choke lever

(2)Close

(3)Open

(4)Fuel tank cock

(5)Close

(6)Open

4.Move the choke lever to the closed position.

5.Set the stop switch to the “RUN” position. Place the unit on a flat, firm place.

Keep the cutting head clear of everything around it.

(1)

(1) Stop switch

6.While holding the unit firmly, pull out the starter rope quickly until engine fires.

![]()

![]() WARNING

WARNING

The product is equipped with a centrifugal clutch mechanism, so the cutting attachment begins to rotate as soon as the engine is started by putting the throttle into the start position. When starting the engine, place the product onto the ground in a flat clear area and hold it firmly in place so as to ensure that neither the cutting part nor the throttle come into contact with any obstacle when the engine starts.

IMPORTANT

Avoid pulling the rope to its end or returning it by releasing the knob. Such actions can cause starter failures.

7.Move the choke lever downward to open the choke. And restart engine.

8.Allow the engine to warm up for a several minutes before starting operation.

NOTE

1.When restarting the engine immediately after stopping it, leave the choke open.

2.Overchoking can make the engine hard to start due to excess fuel. When the engine failed to start after several attempts, open the choke and repeat pulling the rope, or remove the spark plug and dry it.

■STOPPING ENGINE

1.Release the throttle trigger and run the engine for half a minute.

2.Shift the stop switch to the STOP position.

(1)

(1) Stop switch

IMPORTANT

Except for an emergency, avoid stopping the engine while pulling the throttle lever.

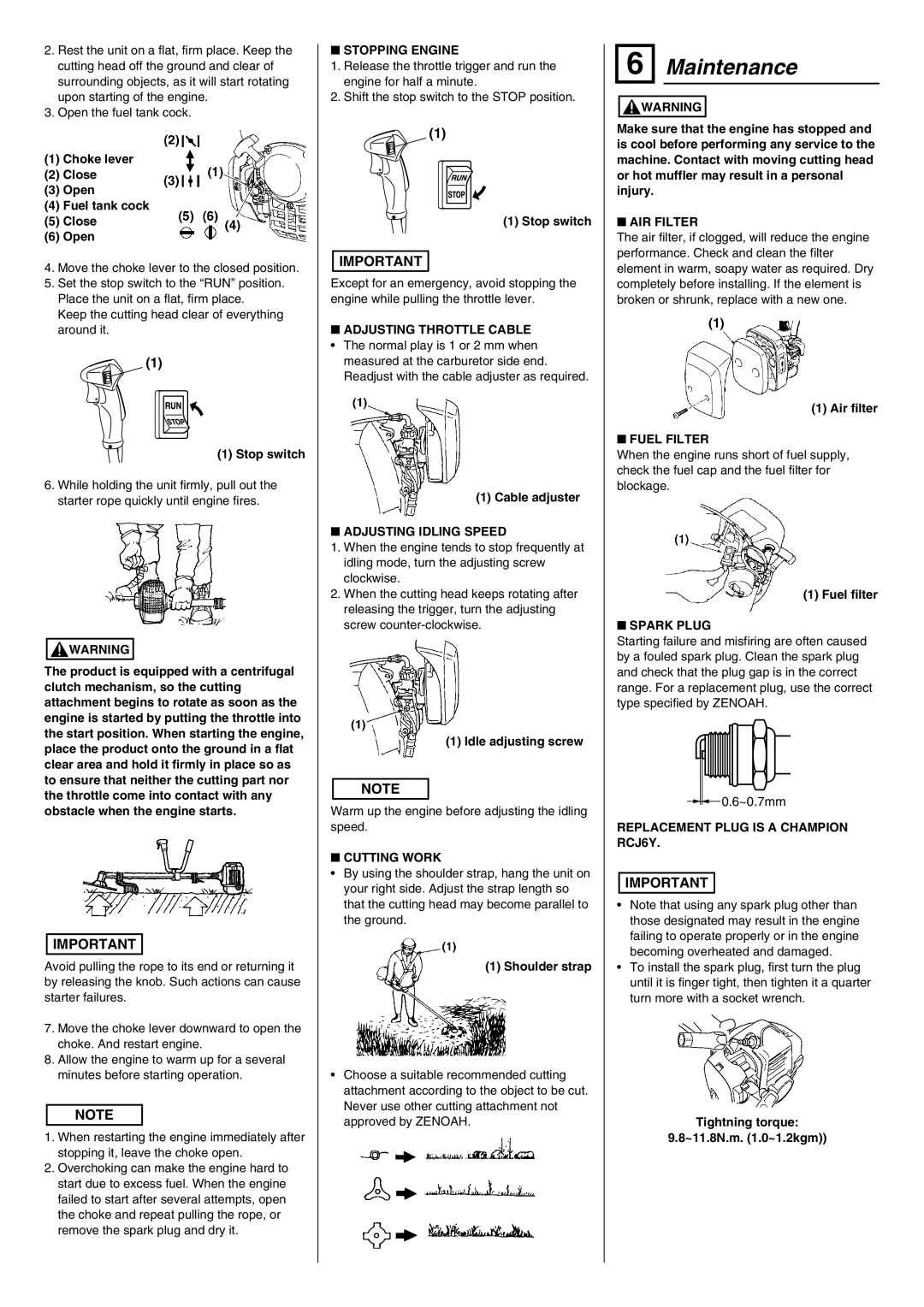

■ADJUSTING THROTTLE CABLE

• The normal play is 1 or 2 mm when measured at the carburetor side end. Readjust with the cable adjuster as required.

(1) Cable adjuster

■ADJUSTING IDLING SPEED

1.When the engine tends to stop frequently at idling mode, turn the adjusting screw clockwise.

2.When the cutting head keeps rotating after releasing the trigger, turn the adjusting screw

(1) Idle adjusting screw

NOTE

Warm up the engine before adjusting the idling speed.

■CUTTING WORK

•By using the shoulder strap, hang the unit on your right side. Adjust the strap length so that the cutting head may become parallel to the ground.

(1)Shoulder strap

•Choose a suitable recommended cutting attachment according to the object to be cut. Never use other cutting attachment not approved by ZENOAH.

6 Maintenance

![]()

![]() WARNING

WARNING

Make sure that the engine has stopped and is cool before performing any service to the machine. Contact with moving cutting head or hot muffler may result in a personal injury.

■AIR FILTER

The air filter, if clogged, will reduce the engine performance. Check and clean the filter element in warm, soapy water as required. Dry completely before installing. If the element is broken or shrunk, replace with a new one.

(1) Air filter

■FUEL FILTER

When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage.

(1) Fuel filter

■SPARK PLUG

Starting failure and misfiring are often caused by a fouled spark plug. Clean the spark plug and check that the plug gap is in the correct range. For a replacement plug, use the correct type specified by ZENOAH.

![]() 0.6~0.7mm

0.6~0.7mm

REPLACEMENT PLUG IS A CHAMPION RCJ6Y.

IMPORTANT

•Note that using any spark plug other than those designated may result in the engine failing to operate properly or in the engine becoming overheated and damaged.

•To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench.

Tightning torque:

9.8~11.8N.m. (1.0~1.2kgm))