3 Setup

■INSTALLING HANDLE

•Mount the handle to the shaft tube and clamp it at a location that is comfortable to you.

■CONNECTING THROTTLE WIRE

1. Remove the air cleaner cover.

2. Connect the end of the throttle wire to the joint on the top of the carburetor.

■CONNECTING SWITCH WIRES

•Connect the switch wires between the engine and the main unit.

■INSTALLING DEBRIS GUARD FOR LINE HEAD

1.Fit the guard skirt on debris guard.

2.Attach the debris guard with the bolts provided while inserting the spacer between the guard and the pipe.

■INSTALLING LINE HEAD

1.While locking the gear shaft by inserting the angled bar(1) into the holder(A)(2) on the gear box, loosen and remove the nut (left- handed).

2.Fit the line head assembly to the gear shaft. Tighten it securely by hand.

■BALANCE UNIT

1.Put on strap and attach unit to strap.

2.Slide clamp up or down until unit balances with head aparting from the ground when using it.

4 Fuel

WARNING!!

•Gasoline is very flammable. Avoid smoking or bringing any flame or sparks near fuel. Make sure to stop the engine and allow it cool before refueling the unit. Select outdoor bare ground for fueling and move at least 3m (10ft) away from the fueling point before starting the engine.

•The Komatsu Zenoah engines are lubricated by oil specially formulated for

•Do not use BIA or TCW

RECOMMENDED MIXING RATIO

GASOLINE 50:OIL 1

•Exhaust emission are controlled by the fundamental engine parameters and components (eq., carburation, ignition timing and port timing) without addition of any major hardware or the introduction of an inert material during combustion.

•These engines are certified to operate on unleaded gasoline.

•Make sure to use gasoline with a minimum octane number of 89 RON (USA/Canada: 87AL)

•If you use a gasoline of a lower octane value than prescribed, there is a danger that the engine temperature may rise and an engine problem such as piston seizing may consequently occur.

•Unleaded gasoline is recommended to reduce the contamination of the air for the sake of your health and the environment.

•Poor quality gasolines or oils may damage sealing rings, fuel lines or fuel tank of the engine.

■HOW TO MIX FUEL

IMPORTANT

Pay attention to agitation.

1.Measure out the quantities of gasoline and oil to be mixed.

2.Put some of the gasoline into a clean, approved fuel container.

3.Pour in all of the oil and agitate well.

4.Pour In the rest of gasoline and agitate again for at least one minute. As some oils may be difficult to agitate depending on oil ingredients, sufficient agitation is necessary for the engine to last long. Be careful that, if the agitation is insufficient, there is an increased danger of early piston seizing due to abnormally lean mixture.

5.Put a clear indication on the outside of the container

container to avoid mixing up with gasoline or other containers.

6.Indicate the contents on outside of container for easy identification.

■FUELING THE UNIT

1.Untwist and remove the fuel cap. Rest the cap on a dustless place.

2.Put fuel into the fuel tank to 80% of the full capacity.

3.Fasten the fuel cap securely and wipe up any fuel spillage around the unit.

WARNING!!

1.Select bare ground for fueling.

2.Move at least 10feet (3meters) away from the fueling point before starting the engine.

3.Stop the engine before refueling the unit. At that time, be sure to sufficiently agitate the mixed gasoline in the container.

FOR YOUR ENGINE LIFE, AVOID;

1.FUEL WITH NO OIL(RAW GASOLINE) – It will cause severe damage to the internal engine parts very quickly.

2.GASOHOL – It can cause deterioration of rubber and/or plastic parts and disruption of engine lubrication.

3.OIL FOR

4.Mixed fuels which have been left unused for a period of one month or more may clog the carburetor and result in the engine failing to operate properly.

5.In the case of storing the product for a long period of time, clean the fuel tank after rendering it empty. Next, activate the engine and empty the carburetor of the composite fuel.

6.In the case of scrapping the used mixed oil container, scrap it only at an authorized repository site.

NOTE

As lot details of quality assurance, read the description in the section Limited Warranty carefully. Moreover, normal wear and change in product with no functional influence are not covered by the warranty. Also, be careful that, if the usage in the instruction manual is not observed as to fhe mixed gasoline, etc. described therein, if may not be covered by the warranty.

5 Operation

■ADJUSTMENTS

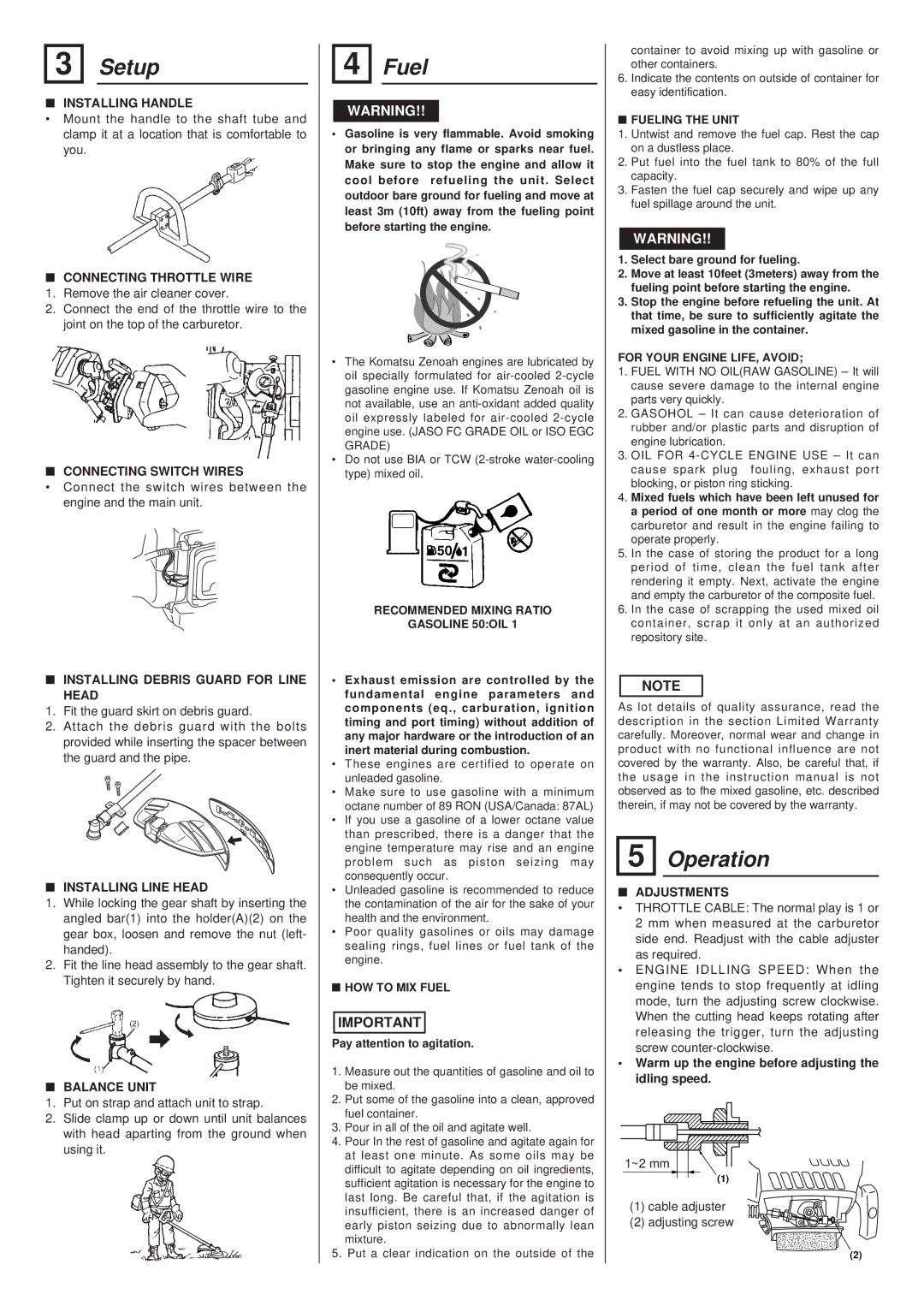

•THROTTLE CABLE: The normal play is 1 or 2 mm when measured at the carburetor side end. Readjust with the cable adjuster as required.

•ENGINE IDLLING SPEED: When the engine tends to stop frequently at idling mode, turn the adjusting screw clockwise. When the cutting head keeps rotating after releasing the trigger, turn the adjusting screw

•Warm up the engine before adjusting the idling speed.

1~2 mm

(1)

(1) cable adjuster

(2) adjusting screw

(2)