8. Operation

4.Never swing the unit so hard as you are in danger of losing your balance or control of the unit.

5.Try to control the cutting motion with the hip rather than placing the full workload on the arm and hands.

6.Take precautions to avoid wire, grass and dead, dry,

ADJUSTING THE LINE LENGTH

•Your brush cutter is equipped with a semi- auto type nylon line head that allows the operator to advance the line without stopping the engine. When the line becomes short, lightly tap the head on the ground while running the engine at full throttle.

•Each time the head is bumped, the line advances about 25 mm. For better effect, tap the head on bear ground or hard soil. Avoid bumping in thick, tall grass as the engine may stall by overload.

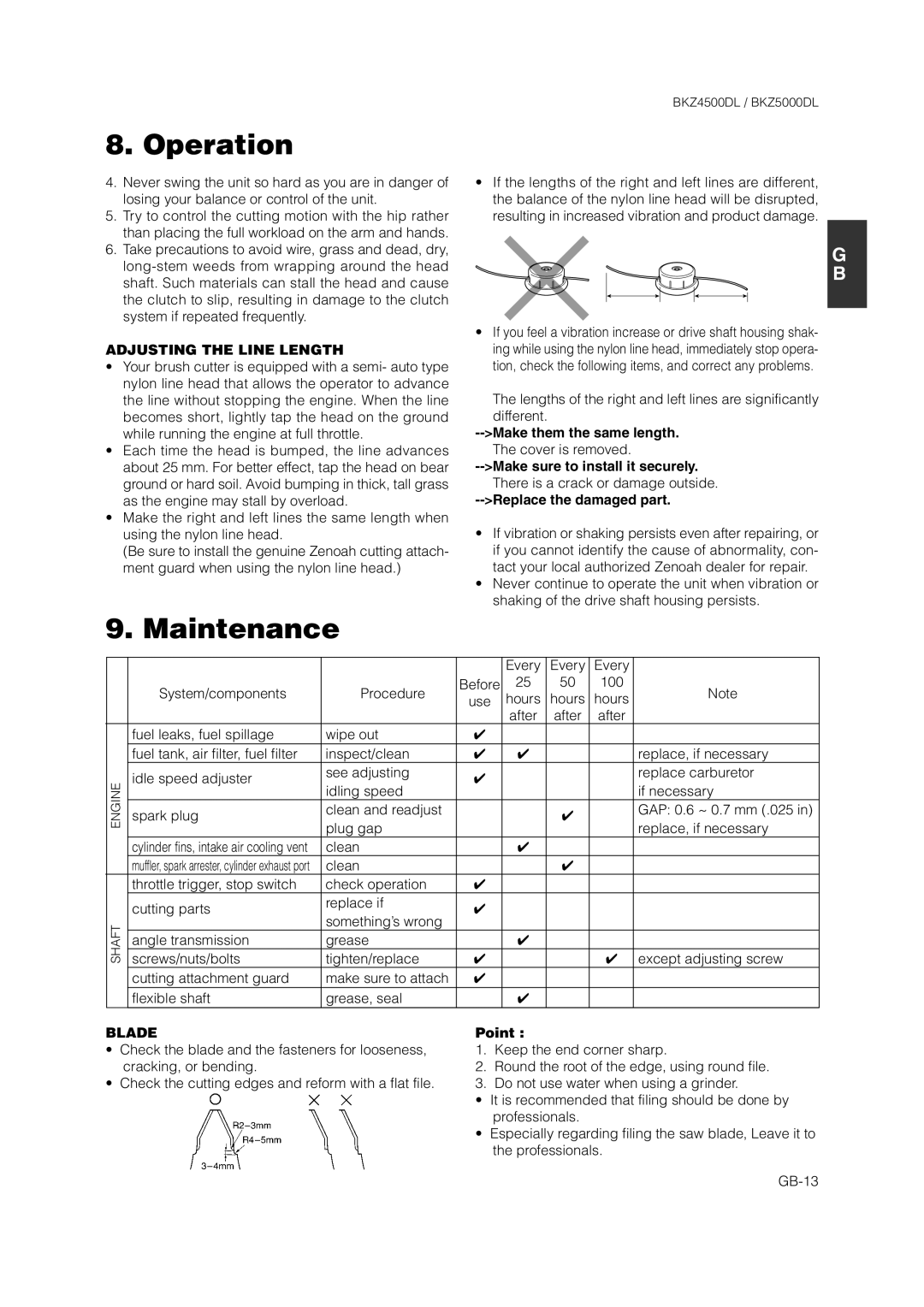

•Make the right and left lines the same length when using the nylon line head.

(Be sure to install the genuine Zenoah cutting attach- ment guard when using the nylon line head.)

BKZ4500DL / BKZ5000DL

•If the lengths of the right and left lines are different, the balance of the nylon line head will be disrupted, resulting in increased vibration and product damage.

G |

B |

•If you feel a vibration increase or drive shaft housing shak- ing while using the nylon line head, immediately stop opera- tion, check the following items, and correct any problems.

The lengths of the right and left lines are significantly different.

•If vibration or shaking persists even after repairing, or if you cannot identify the cause of abnormality, con- tact your local authorized Zenoah dealer for repair.

•Never continue to operate the unit when vibration or shaking of the drive shaft housing persists.

9. Maintenance

ENGINE

SHAFT

|

|

| Every | Every | Every |

| |

System/components | Procedure | Before | 25 | 50 | 100 | Note | |

use | hours | hours | hours | ||||

|

|

| |||||

|

|

| after | after | after |

| |

fuel leaks, fuel spillage | wipe out | ✔ |

|

|

|

| |

fuel tank, air filter, fuel filter | inspect/clean | ✔ | ✔ |

|

| replace, if necessary | |

idle speed adjuster | see adjusting | ✔ |

|

|

| replace carburetor | |

idling speed |

|

|

| if necessary | |||

|

|

|

|

| |||

spark plug | clean and readjust |

|

| ✔ |

| GAP: 0.6 ~ 0.7 mm (.025 in) | |

plug gap |

|

|

| replace, if necessary | |||

|

|

|

|

| |||

cylinder fins, intake air cooling vent | clean |

| ✔ |

|

|

| |

muffler, spark arrester, cylinder exhaust port | clean |

|

| ✔ |

|

| |

throttle trigger, stop switch | check operation | ✔ |

|

|

|

| |

cutting parts | replace if | ✔ |

|

|

|

| |

something’s wrong |

|

|

|

| |||

|

|

|

|

|

| ||

angle transmission | grease |

| ✔ |

|

|

| |

screws/nuts/bolts | tighten/replace | ✔ |

|

| ✔ | except adjusting screw | |

cutting attachment guard | make sure to attach | ✔ |

|

|

|

| |

flexible shaft | grease, seal |

| ✔ |

|

|

|

BLADE

•Check the blade and the fasteners for looseness, cracking, or bending.

•Check the cutting edges and reform with a flat file.

Point :

1.Keep the end corner sharp.

2.Round the root of the edge, using round file.

3.Do not use water when using a grinder.

•It is recommended that filing should be done by professionals.

•Especially regarding filing the saw blade, Leave it to the professionals.