Maintenance

Maintenance, replacement, or repair of the emission control device and systems may be performed by any

■ MAINTENANCE CHART

|

|

| every | every | every |

|

|

|

| 25 | 50 | 100 |

|

system/compornent | procedure | before | hours | hours | hours | note |

|

| use | after | after | after |

|

fuel leaks, fuel spillage | wipe out | ✔ |

|

|

|

|

|

|

|

|

|

|

|

fuel tank, air filter, fuel filter | inspect/clean | ✔ | ✔ |

|

| replace, if necessary |

idle adjusting screw | see ■ADJUSTING | ✔ |

|

|

| replace carburetor |

IDLING SPEED (p.13) |

|

|

| if necessary | ||

|

|

|

|

| ||

spark plug | clean and readjust |

|

| ✔ |

| GAP: .025in(0.6~0.7mm) |

plug gap |

|

|

| replace, if necessary | ||

|

|

|

|

| ||

cylinder fins, intake air cooling vent | clean |

| ✔ |

|

|

|

|

|

|

|

|

|

|

muffler, spark arrester, cylinder exhaust port | clean |

|

|

| ✔ |

|

throttle lever, ignition switch | check operation | ✔ |

|

|

|

|

|

|

|

|

|

|

|

screws/nuts/bolts | tighten/replace | ✔ |

|

| ✔ | not adjusting screws |

|

|

|

|

|

|

|

![]()

![]() WARNING

WARNING

•Before cleaning, inspecting or repairing your unit, make sure that engine has stopped and is cool. Disconnect the spark plug terminal to avoid accidental engine starts.

■DAILY INSPECTION

•Remove grass or dust, from the entire body.

•Check that all nuts and screws are securely tightened, and no parts are missing.

•Check for leakage of fuel.

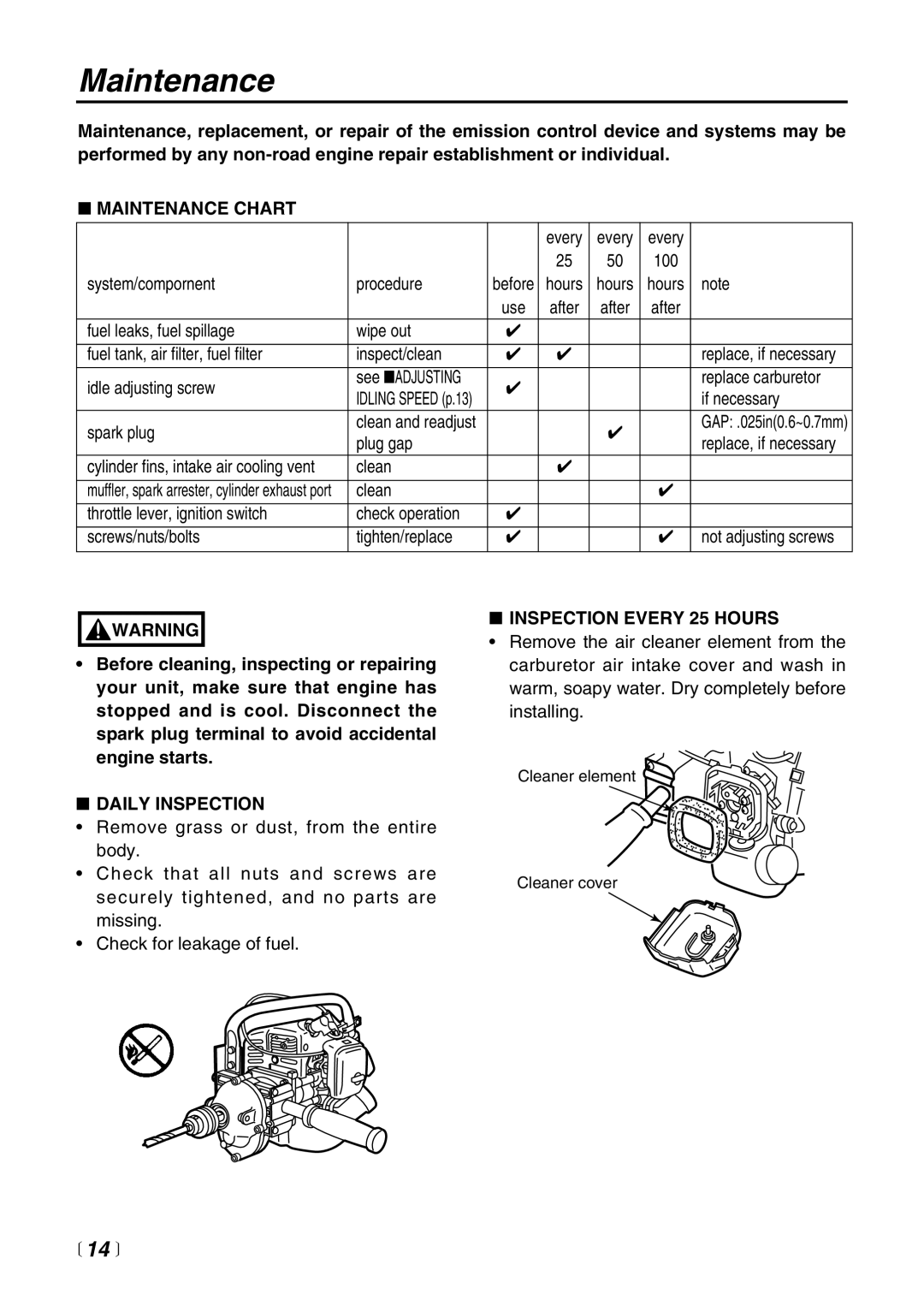

■INSPECTION EVERY 25 HOURS

•Remove the air cleaner element from the carburetor air intake cover and wash in warm, soapy water. Dry completely before installing.

Cleaner element

Cleaner cover

14