DRT900 specifications

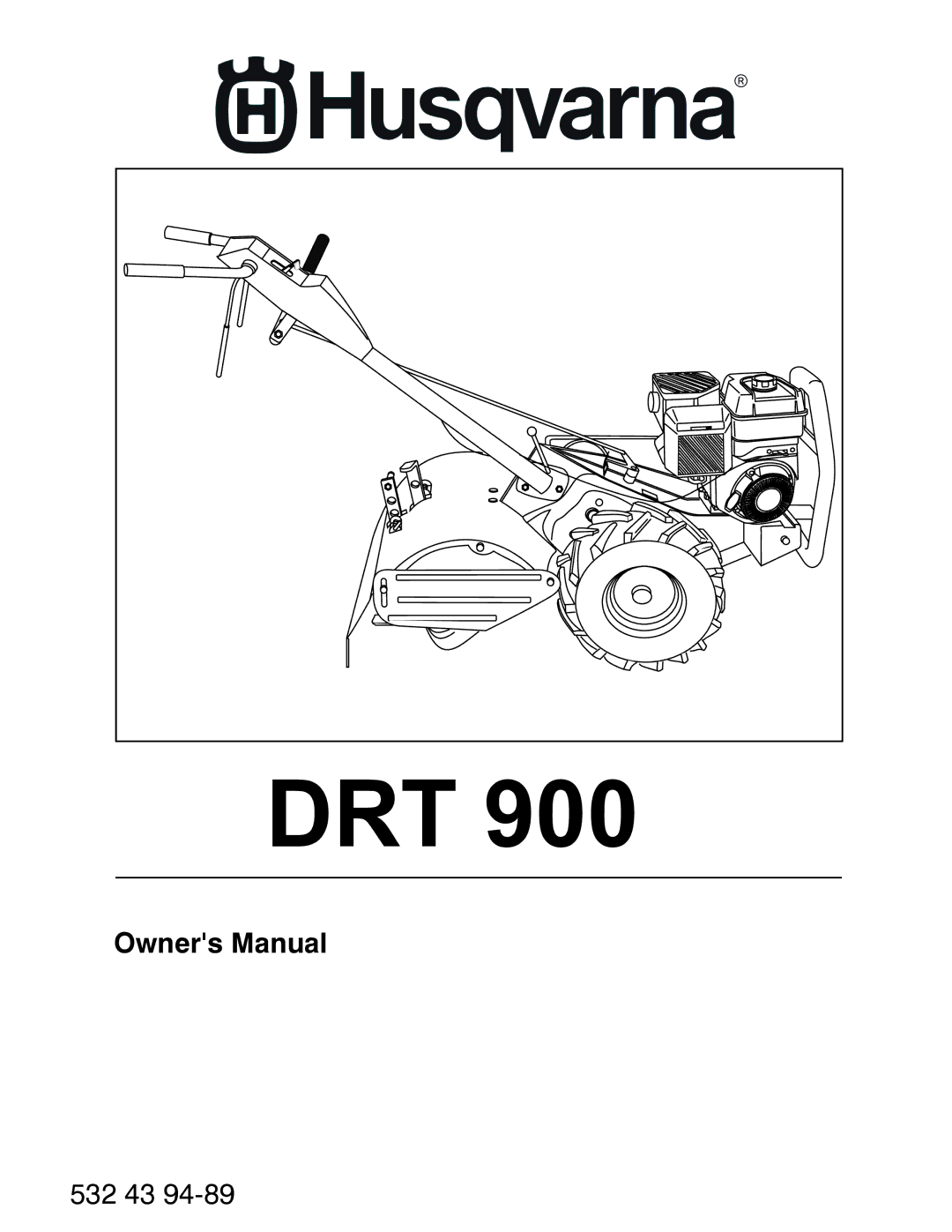

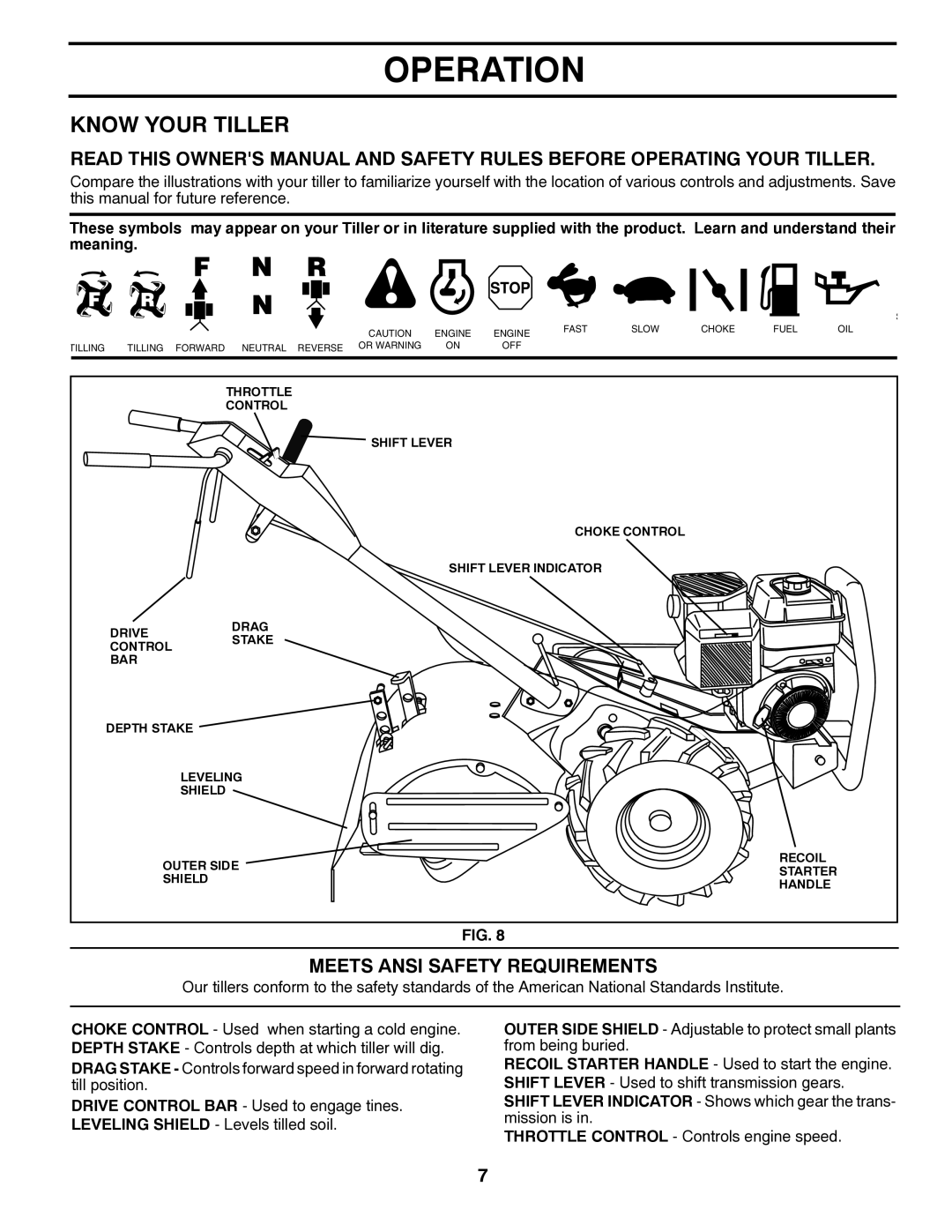

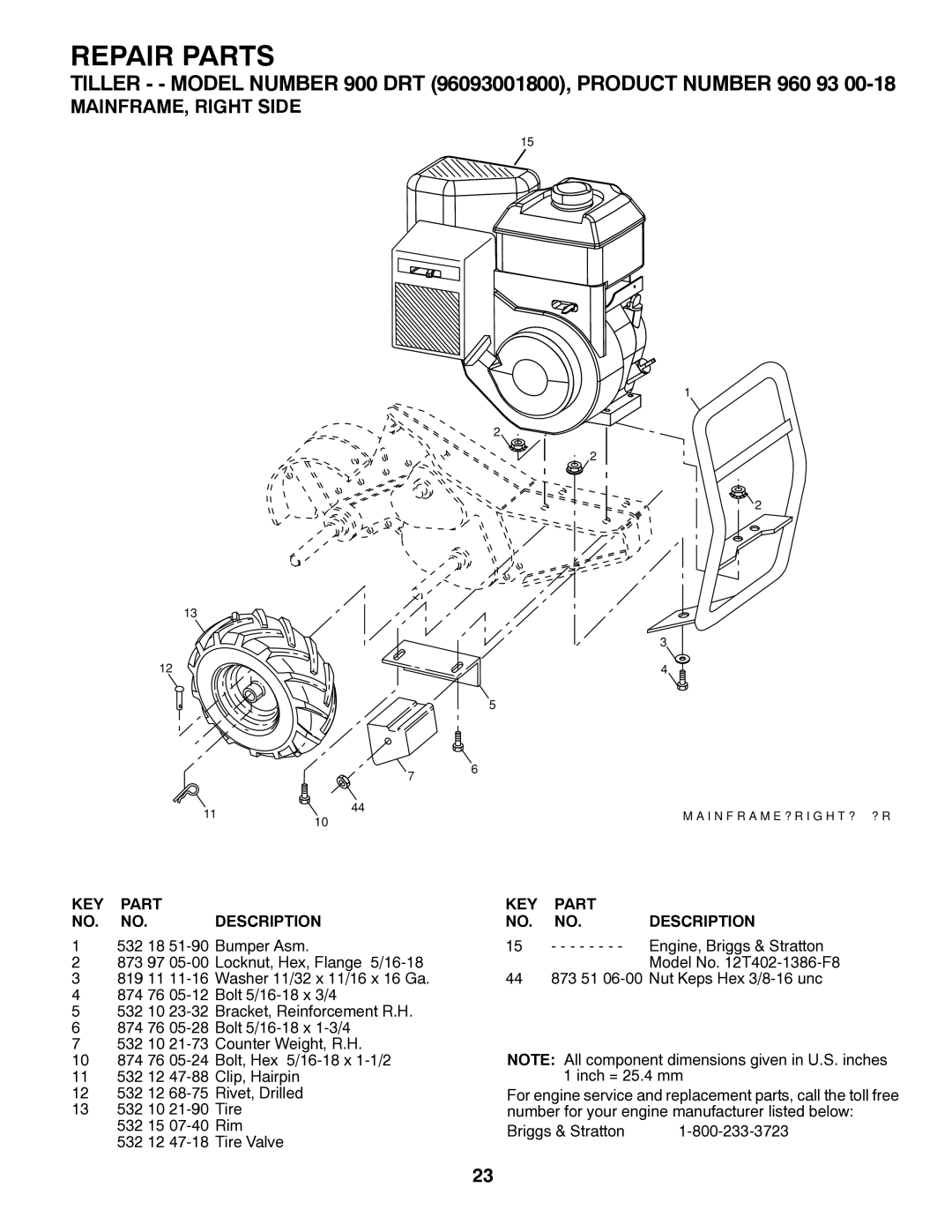

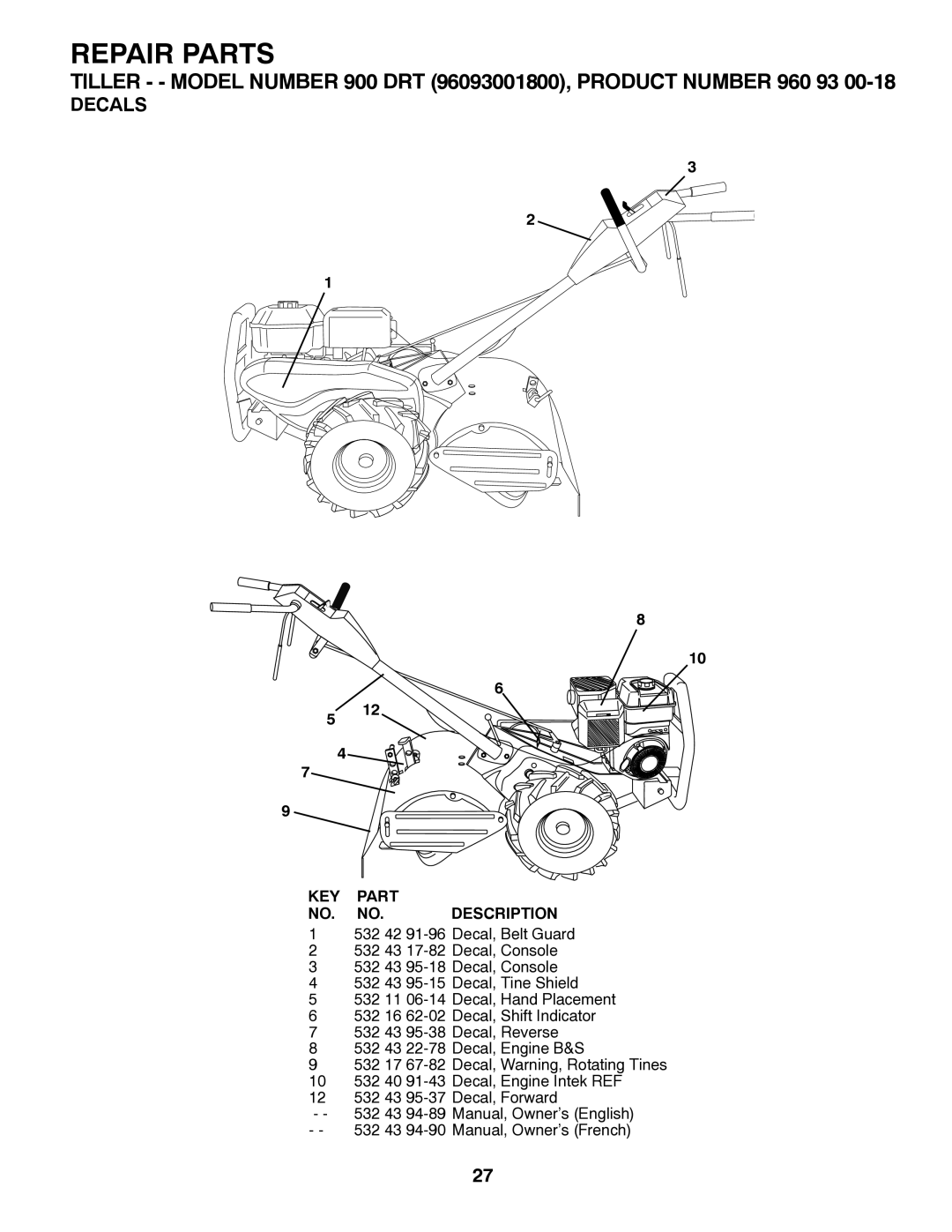

The Husqvarna DRT900 is an advanced, highly versatile tiller designed for homeowners and gardening enthusiasts looking to cultivate their gardens efficiently. This machine combines power, performance, and ease of use, making it an ideal choice for both small and large garden areas. With its robust construction and cutting-edge technology, the DRT900 is built to deliver outstanding results with minimal effort.One of the standout features of the DRT900 is its powerful engine. The unit is equipped with a reliable and efficient petrol engine that provides ample torque for breaking hard soil, turning over compost, and preparing seedbeds. Its high-performance design enables it to tackle tough terrains, making it suitable for various gardening tasks.

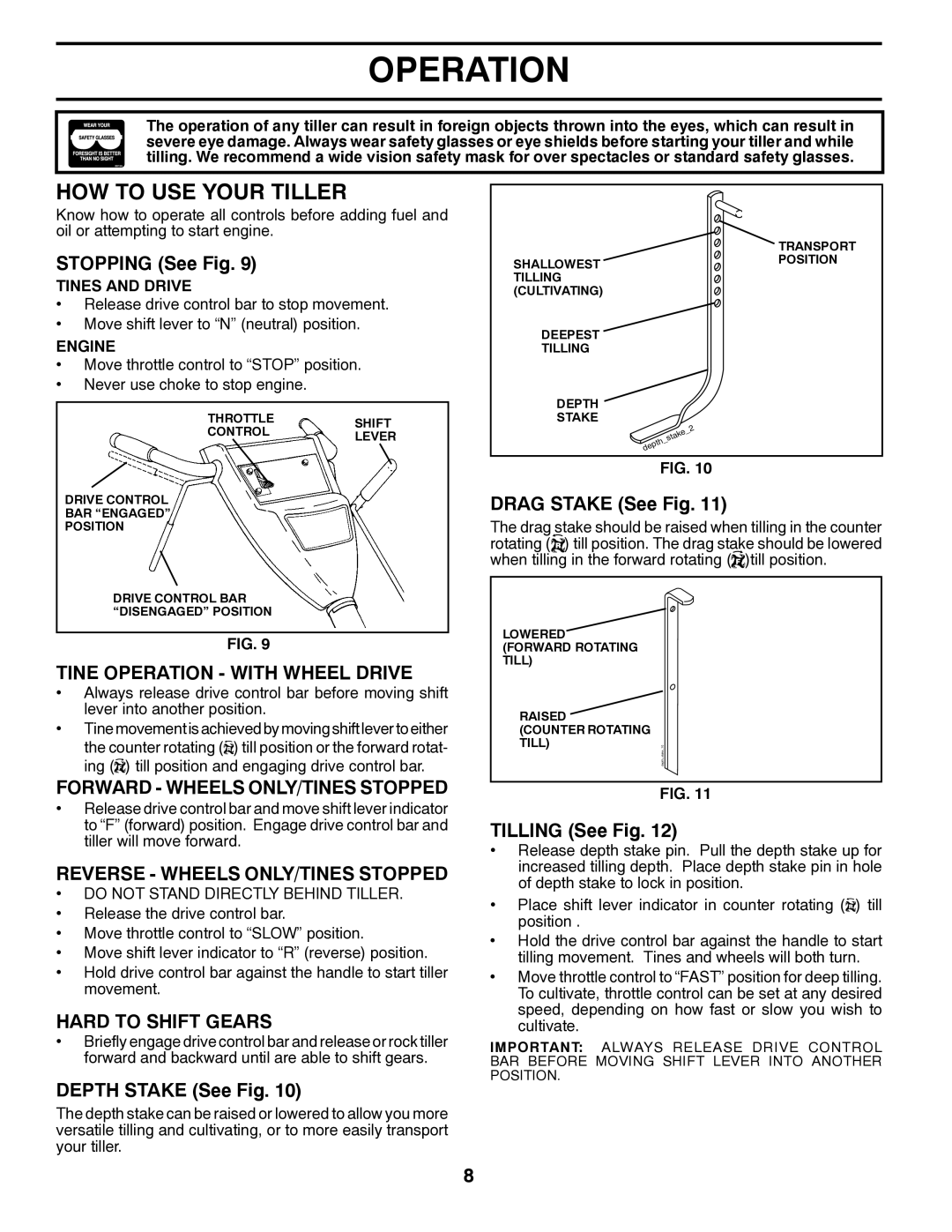

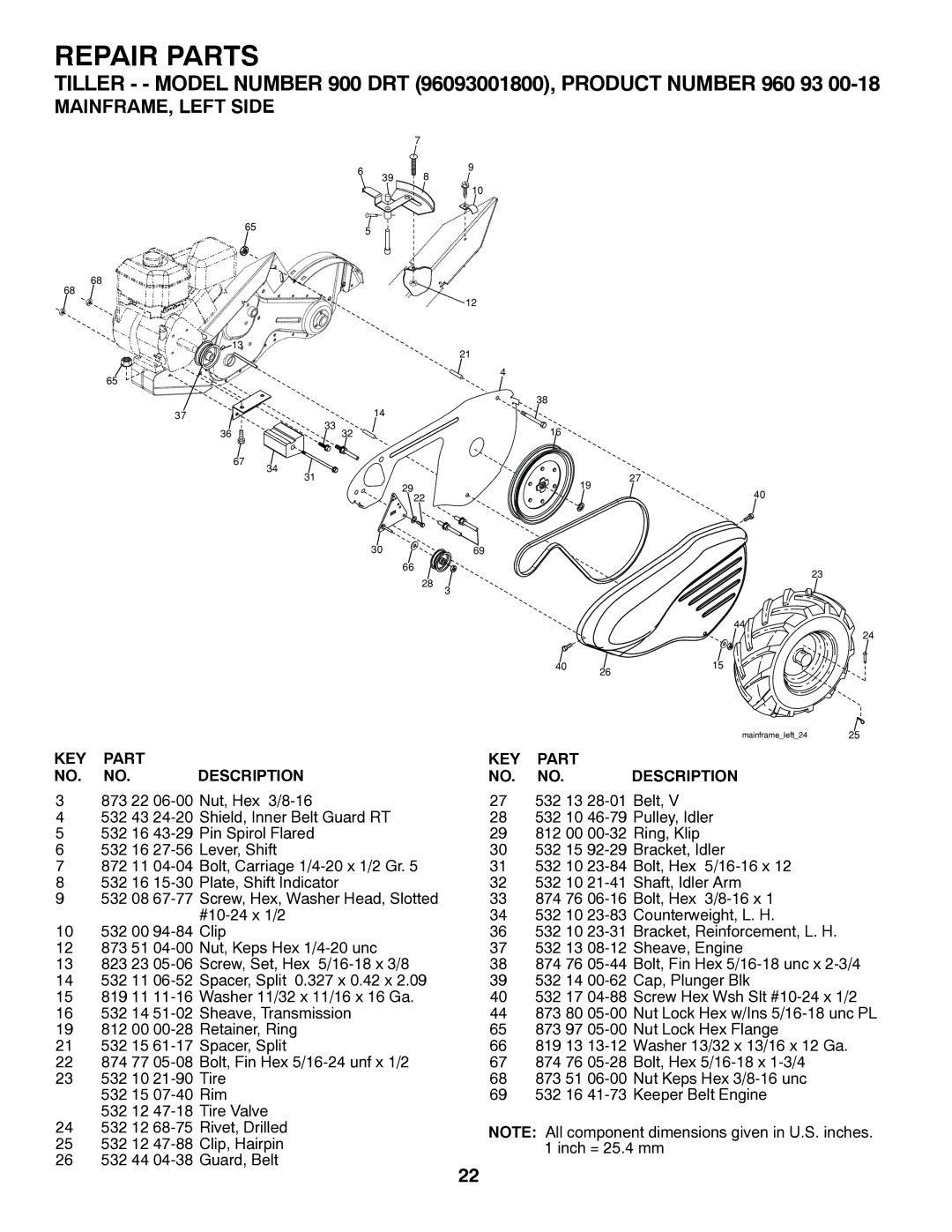

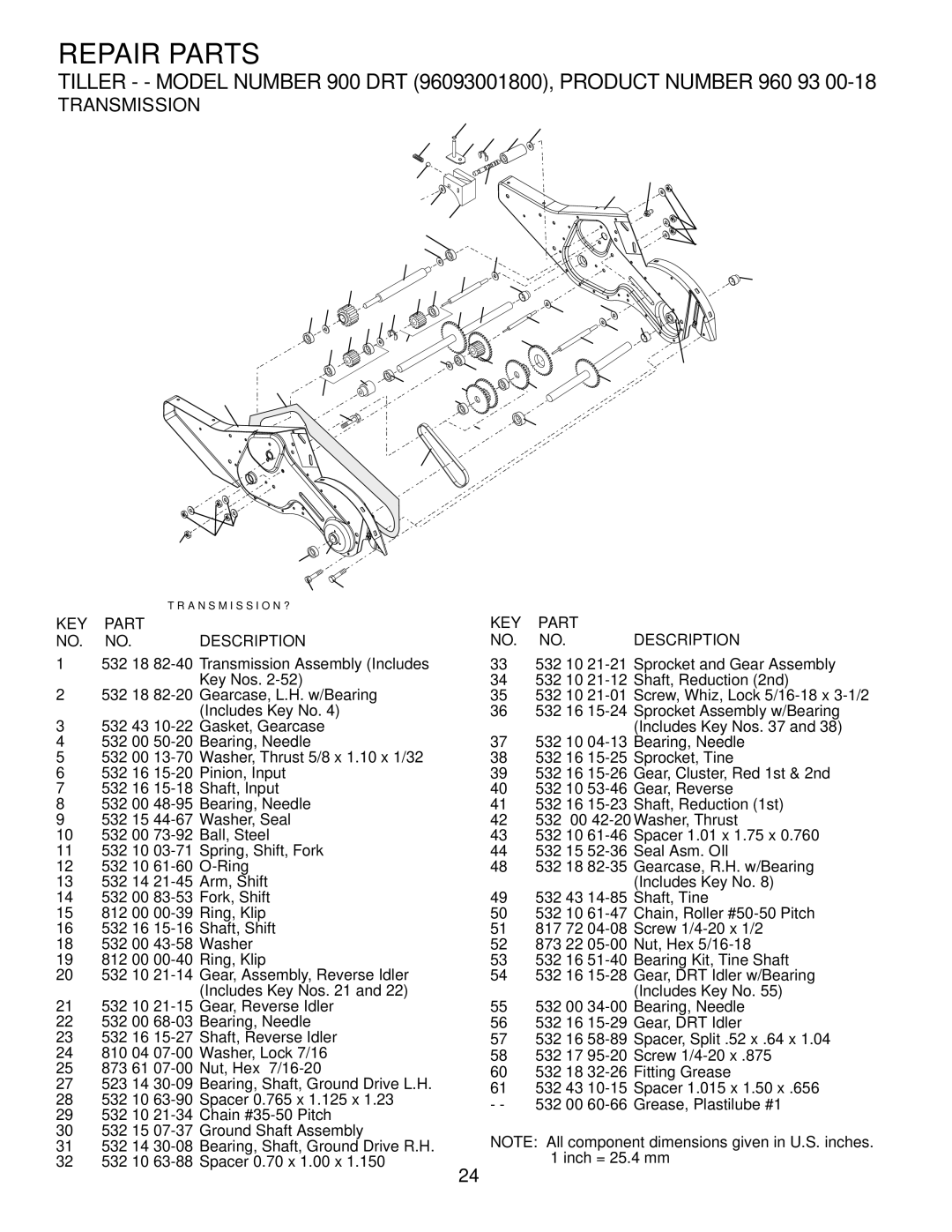

The DRT900 features a unique, reverse gear mechanism which enhances maneuverability. This innovative feature allows users to easily navigate around obstacles in the garden, such as trees or planting beds, without straining the machine or the operator. Additionally, its adjustable tilling width makes it versatile to accommodate different garden sizes and soil types, allowing efficient preparation of larger plots as well as tighter spaces.

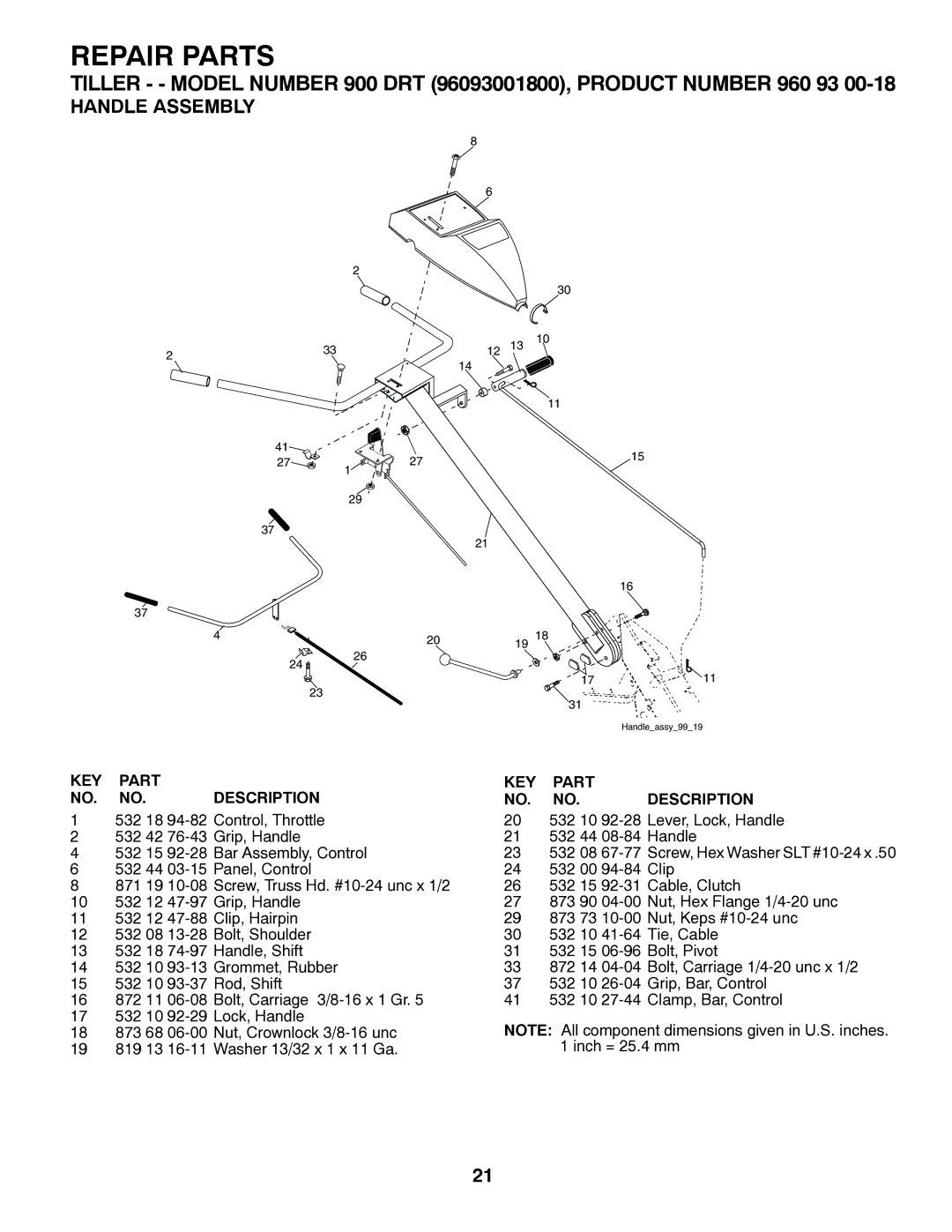

Another key aspect of the Husqvarna DRT900 is its intelligent design. The ergonomic handlebar is adjustable, providing comfort for users of varying heights and reducing operator fatigue during extended use. The machine's lightweight frame and compact design facilitate easy transport and storage, ensuring it can be moved or packed away with minimal hassle.

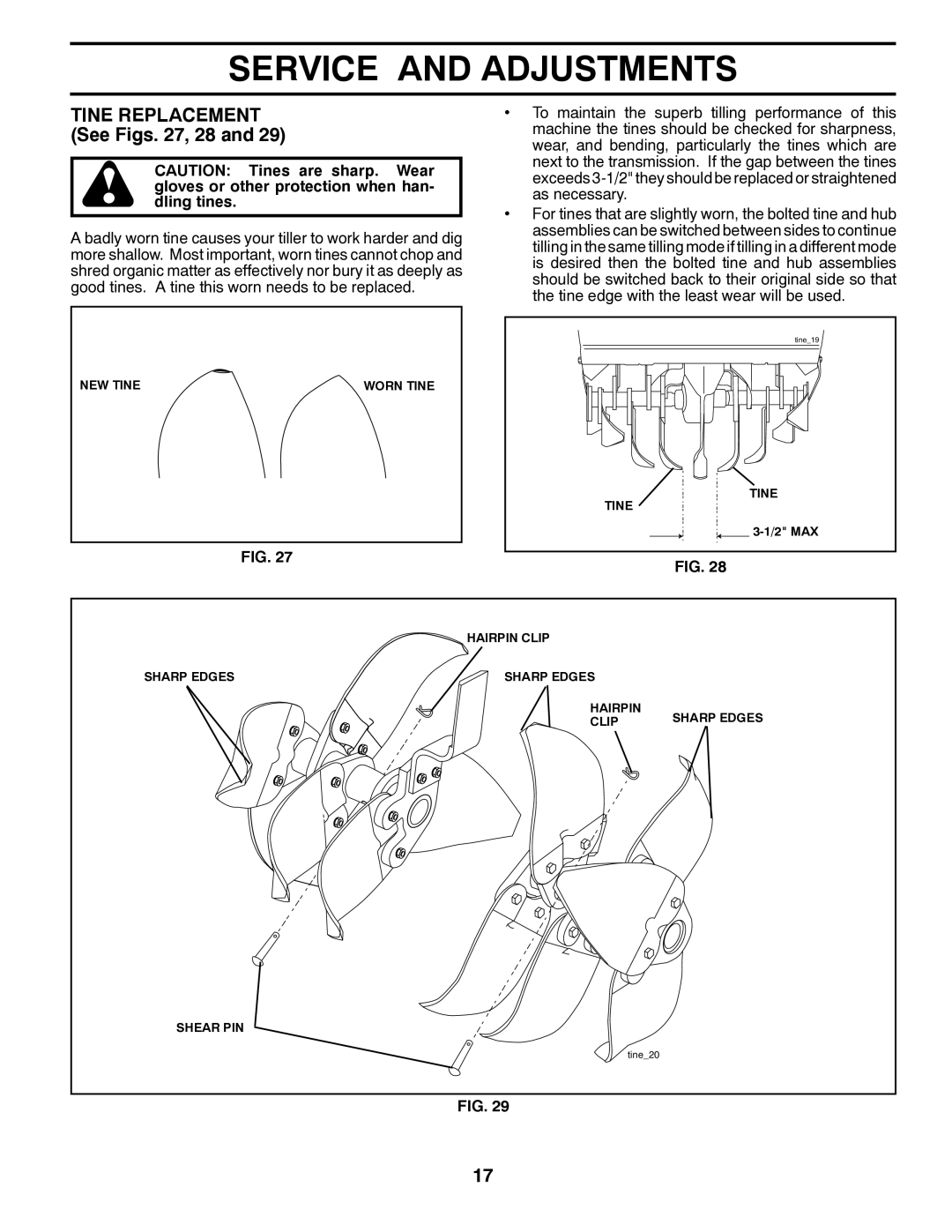

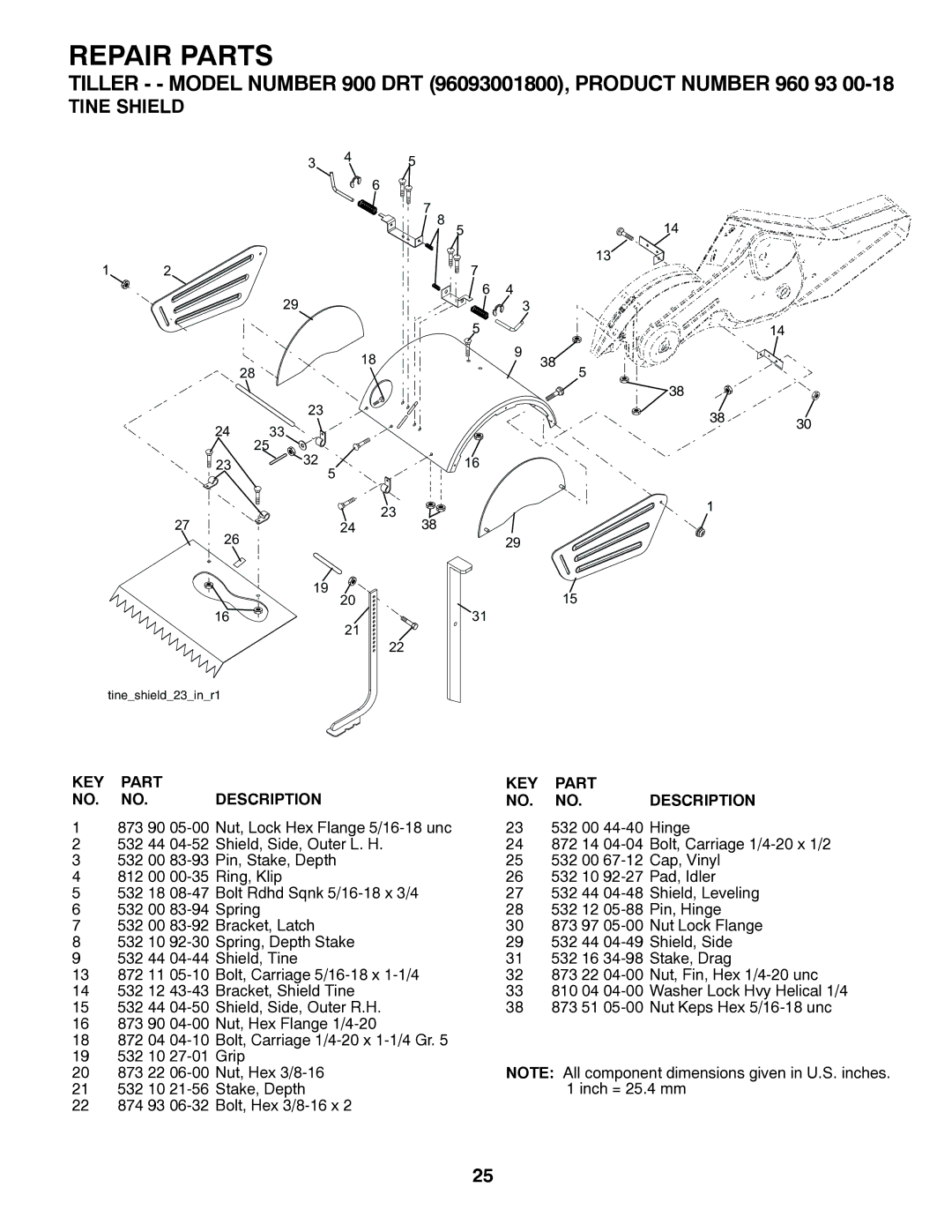

Furthermore, the DRT900 is equipped with durable, heavy-duty tines that penetrate deeply into the soil for effective tilling and aeration. These tines can be easily changed or serviced, ensuring the longevity of the machine and optimizing its performance as required.

Husqvarna has also incorporated safety features into the DRT900, including an automatic clutch that minimizes the risk of accidental engagement. This provides peace of mind for users, especially beginners. The machine is engineered for easy maintenance access, allowing for simple inspections and repairs, thus ensuring longevity and reliability over time.

In summary, the Husqvarna DRT900 is a top-tier tiller that combines power, versatility, and user-friendly design. With its robust engine, maneuverability features, ergonomic construction, and durability, it stands out as an essential tool for any garden enthusiast looking to achieve professional-level results with ease. With the DRT900, cultivating your garden has never been simpler or more efficient.