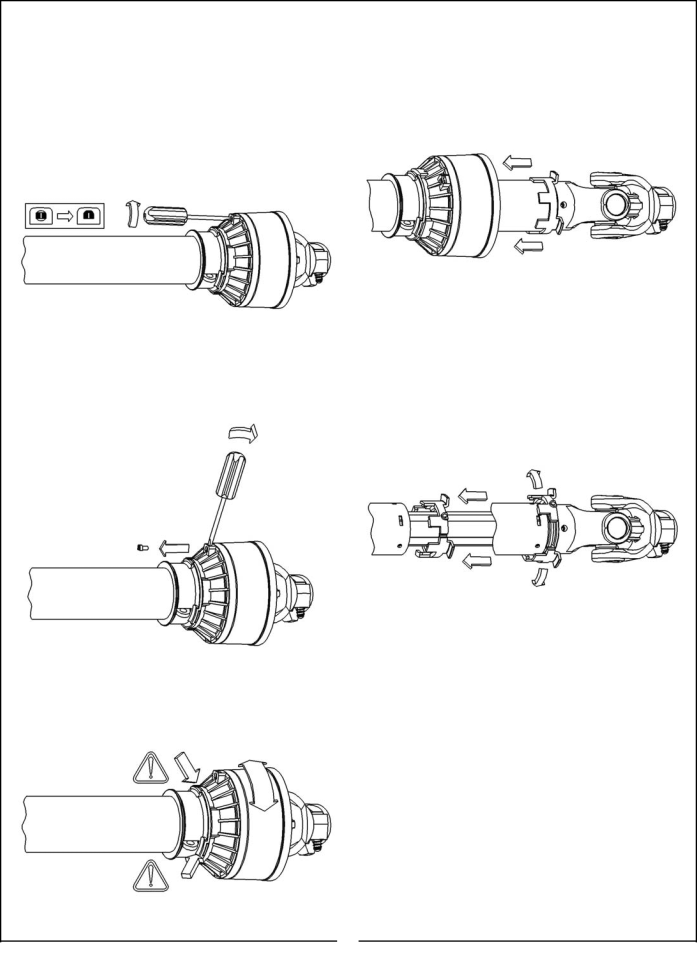

NOTE: In some instances, sliding the yoke shield back will make lubrication, inspection and cleaning of the universal joints more convenient. Proceed as follows:

1.Using a flat blade screwdriver, rotate the fasten- ing pin in its seat 1/2 turn until the head of the pin becomes unlocked in its housing on the cones. (Figure

Figure

2.Lever up the pin through the slot, until the pin comes out. (Figure

Figure

4.Remove the cones from the

5.Remove the connecting ring from its housing on the yoke and, at the same time, from the slots of the guard tube, then move away the ring and the tube. (Figure

Figure

3. Rotate the soft cone until the slots are aligned | Reassembly is in the reverse order |

with the corresponding ones of the rigid cone. |

|

(Figure |

|

|

|

Figure |

|

|

|

11