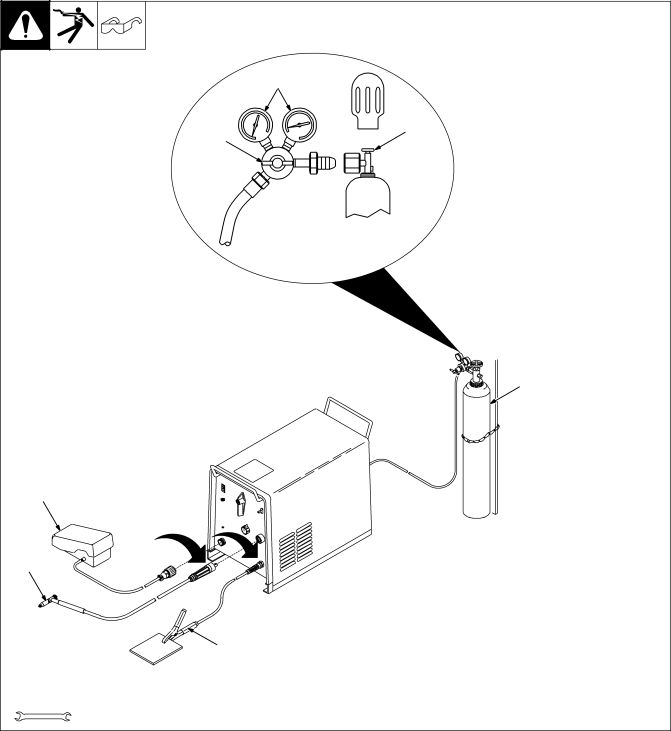

4-3. Typical TIG Connections

6

Y Turn Off power before mak- ing connections.

1 Remote Control

2 Torch

Connect to receptacles as shown.

3 Work Clamp

4 Cylinder

Chain or secure cylinder to running

75gear, wall, or other stationary support.

5 Cylinder Valve

Open valve slightly so gas flow blows dirt from valve. Close valve.

6 Regulator/Flow Gauge

Install so face is vertical.

7 Flow Adjust

Typical flow rate is 20 cfh (cubic feet per hour) (9.4 L/min).

4

1

2

3

Tools Needed:

5/8, | Ref. |

|