Installation Instructions

Minimum Clearance Other Than Alcove or Closet Installation

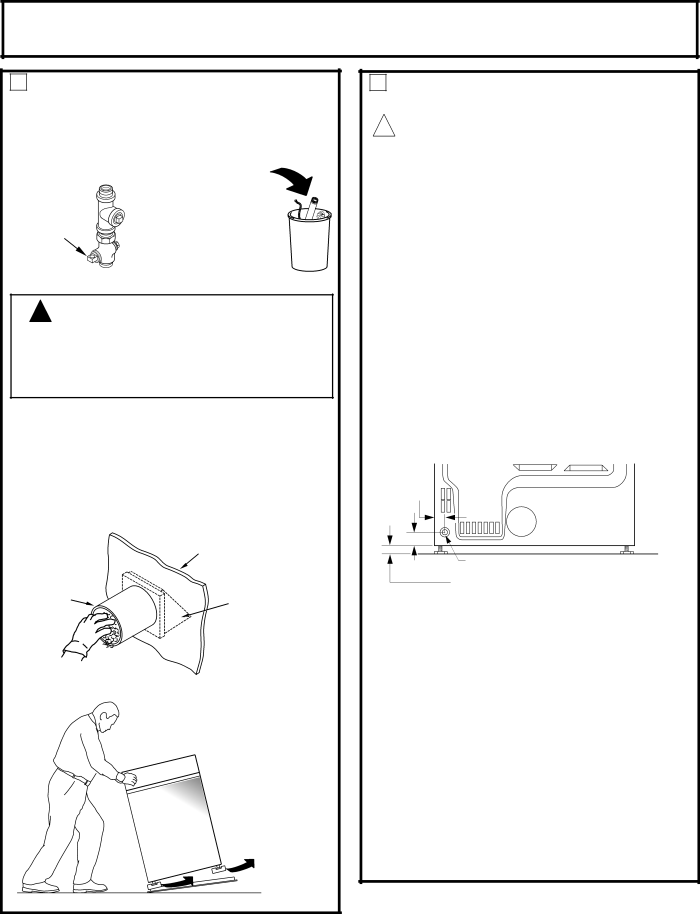

Minimum clearance to combustible surfaces and for air opening are: 0 in. clearance both sides and 1 in. rear. Consideration must be given to provide adequate clearance for installation and service.

1PREPARING FOR INSTALLATION

OF NEW DRYER

TIP: Install your dryer before installing your washer. This will allow better access when installing dryer exhaust.

DISCONNECTING GAS

TURN GAS | DISCONNECT AND DISCARD OLD | |

FLEXIBLE GAS CONNECTOR AND | ||

TO THE OFF | ||

OLD TRANSITION DUCTING | ||

POSITION. | ||

MATERIAL. REPLACE WITH NEW | ||

| ||

| CSA(AGA) APPROVED FLEXIBLE | |

| GAS LINE CONNECTOR AND UL | |

| APPROVED TRANSITION DUCT. |

![]() WARNING - NEVER REUSE OLD FLEXIBLE CONNECTORS.

WARNING - NEVER REUSE OLD FLEXIBLE CONNECTORS.

The use of old flexible connectors can cause leaks and personal injury. Always use new flexible connectors when installing gas appliances.

REMOVING LINT FROM WALL

EXHAUST OPENING

•Remove and discard existing plastic or metal foil transition duct and replace with UL listed transition duct.

| WALL | |

INTERNAL DUCT | CHECK THAT EXHAUST | |

OPENING | ||

HOOD DAMPER OPENS | ||

| ||

| AND CLOSES FREELY. |

TILT THE DRYER SIDEWAYS

AND REMOVE THE FOAM

SHIPPING PADS BY

PULLING AT THE SIDES

AND BREAKING THEM

AWAY FROM THE DRYER

LEGS. BE SURE TO

REMOVE ALL OF THE

FOAM PIECES AROUND

THE LEGS.

2GAS REQUIREMENTS

![]() WARNING

WARNING

•Installation must conform to local codes and ordinances, or in their absence, the NATIONAL FUEL

GAS CODE, ANSI Z223.

•This gas dryer is equipped with a Valve & Burner Assembly for use only with natural gas. Using conversion kit WE25X0217, your local service organization can convert this dryer for use with propane (LP) gas. ALL CONVERSIONS MUST BE MADE BY

PROPERLY TRAINED AND QUALIFIED PERSONNEL AND IN ACCORDANCE WITH LOCAL CODES AND ORDINANCE

REQUIREMENTS.

•The dryer must be disconnected from the gas supply piping system during any pressure testing of that system at a test pressure in excess of 0.5 PSI (3.4 KPa).

•The dryer must be isolated from the gas supply piping system by closing the equipment

DRYER GAS SUPPLY CONNECTION

2" |

|

3/8" NPT MALE THREAD GAS SUPPLY | |

|

NOTE: Add to vertical dimension the distance between cabinet bottom to floor.

GAS SUPPLY

•A

•Supply line is to be

•Use pipe thread sealer compound or Teflon tape appropri- ate for natural or LP gas.

•You must use with this dryer a flexible metal connector listed connector ANSI Z21.24 / CSA 6.10. The length of the connect shall not exceed 3 ft.

•Connect flexible metal connector to dryer and gas supply.

•Open

2