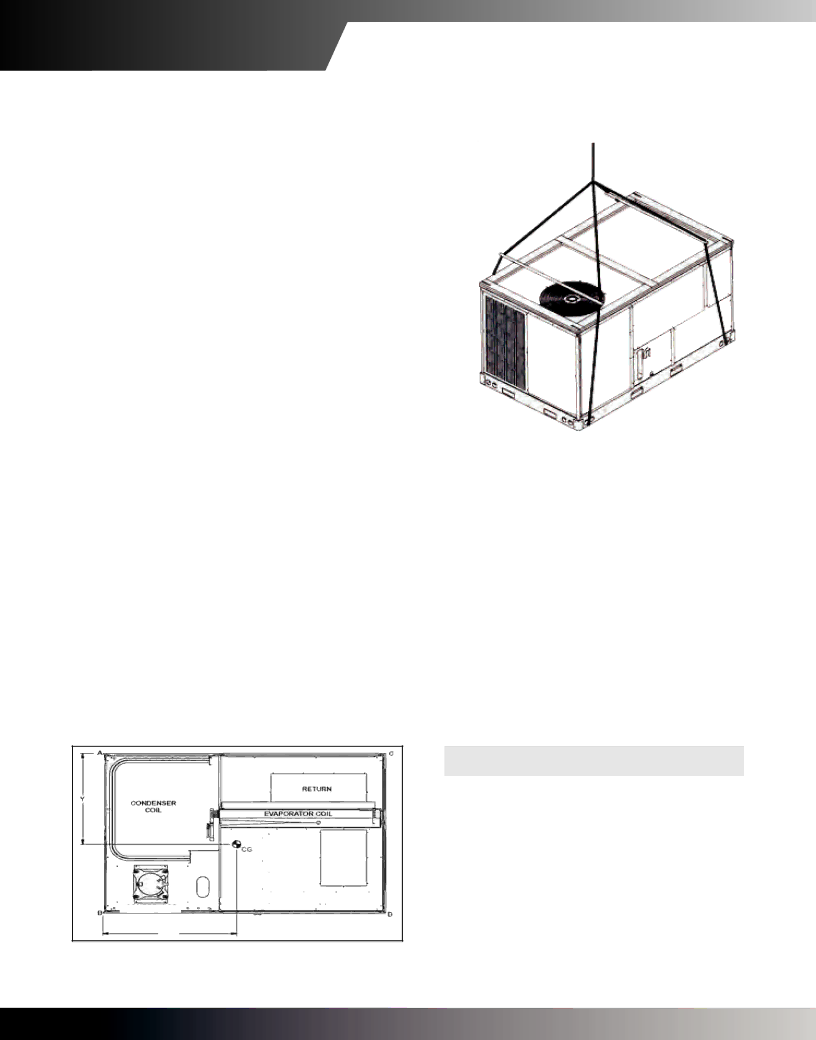

SS-CPC36-72 specifications

The Goodman Manufacturing SS-CPC36-72 is a top-tier commercial rooftop unit designed for optimal heating and cooling in a variety of settings. This unit embodies the cutting-edge technology and engineering expertise that Goodman is known for. Ideal for medium to large commercial buildings, the SS-CPC36-72 stands out with its robust performance and energy efficiency.One of the defining features of this unit is its high-efficiency scroll compressor, which significantly enhances energy savings while providing reliable performance. The compressor operates quietly and has fewer moving parts compared to traditional compressors, resulting in lower maintenance requirements. This feature is critical for environments where noise levels must be minimized.

Additionally, the Goodman SS-CPC36-72 is designed with a multi-stage cooling system. This technology allows the unit to operate at varying capacities, adapting to real-time cooling needs. This not only improves comfort levels in the space but also optimizes energy use, leading to reduced operational costs.

Another notable characteristic of this model is its environmentally friendly R-410A refrigerant. The use of this refrigerant contributes to lower global warming potential, aligning with modern sustainability goals. This makes the Goodman SS-CPC36-72 not just a powerful unit but also an environmentally conscious choice for businesses looking to reduce their carbon footprint.

The unit is built with durable materials, ensuring longevity and resilience in various weather conditions. From the corrosion-resistant cabinet to the high-quality insulation, every component is crafted to withstand the rigors of commercial environments. This durability translates to reduced replacement costs over time, making it a wise investment.

Ease of installation and maintenance is another hallmark of the Goodman SS-CPC36-72. The unit is designed with serviceability in mind, featuring accessible components that simplify routine checks and repairs. This means reduced downtime and enhanced productivity for businesses relying on consistent climate control.

In summary, the Goodman Mfg SS-CPC36-72 is a highly efficient and versatile rooftop HVAC unit. With its advanced compressor technology, environmentally friendly refrigerant, robust construction, and easy maintenance features, it is well-equipped to meet the demands of modern commercial spaces while delivering exceptional performance and reliability.