Disassembly/Assembly Instructions – 3" Disc Sander (continued)

12.Carefully secure the 01739 Housing in vise with aluminum or bronze jaws. Hold the back portion of the housing opposite the exhaust cover so as not to crush the housing.

13.Install the 01744 Silencer into the exhaust cover.

14.Apply a small amount of Loctite® #567 to the threads of the 01739 Housing and using a

15.Install the 50187 3" Dynapad.

Motor Assembly Complete. Tool Assembly Complete. Please allow 30 minutes for adhesives to cure before operating tool.

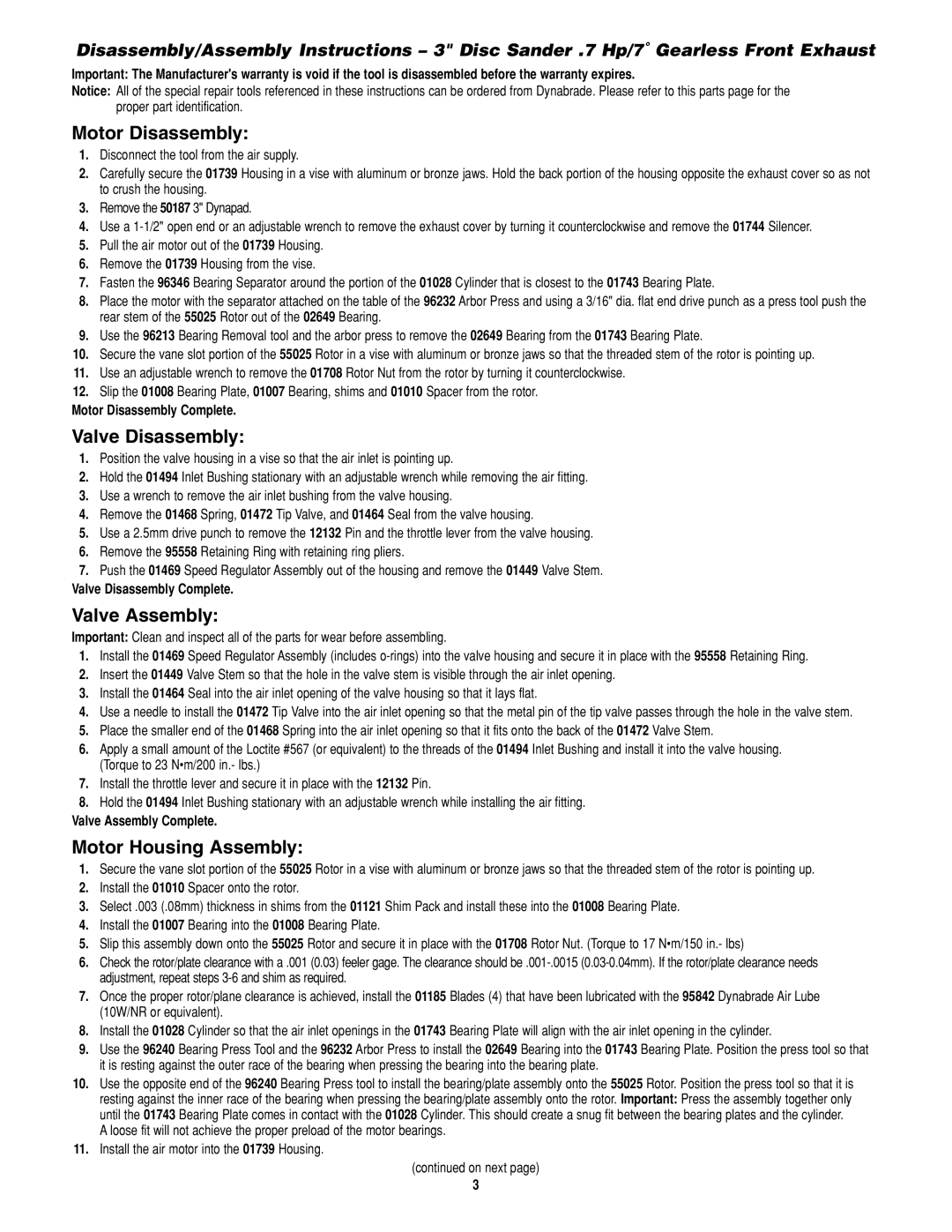

Throttle Lever Positioning:

1.Secure the holding flats of the valve housing in a vise with aluminum or bronze jaws so that the 01739 Housing is pointing up.

2.Slip the 01558 Collar down onto the valve housing to expose the 01461 Lock Nut.

3.With a firm hold on the 01739 Housing, use a 34mm or an adjustable wrench to turn the 01461 Lock Nut counterclockwise to loosen the 01739 Housing from the valve housing.

4.Orient the throttle lever to the operators desired grip and positioning. Note: Allow for additional rotation of the 01739 Housing as the 01461 LocK Nut is tightened.

5.With a firm hold on the 01739 Housing to reduce its rotation, use a 34mm or an adjustable wrench to tighten the 01461 Lock Nut. (Torque to 45 N•m/400 in.- lbs.)

Loctite® is a registered trademark of the Loctite Corp.

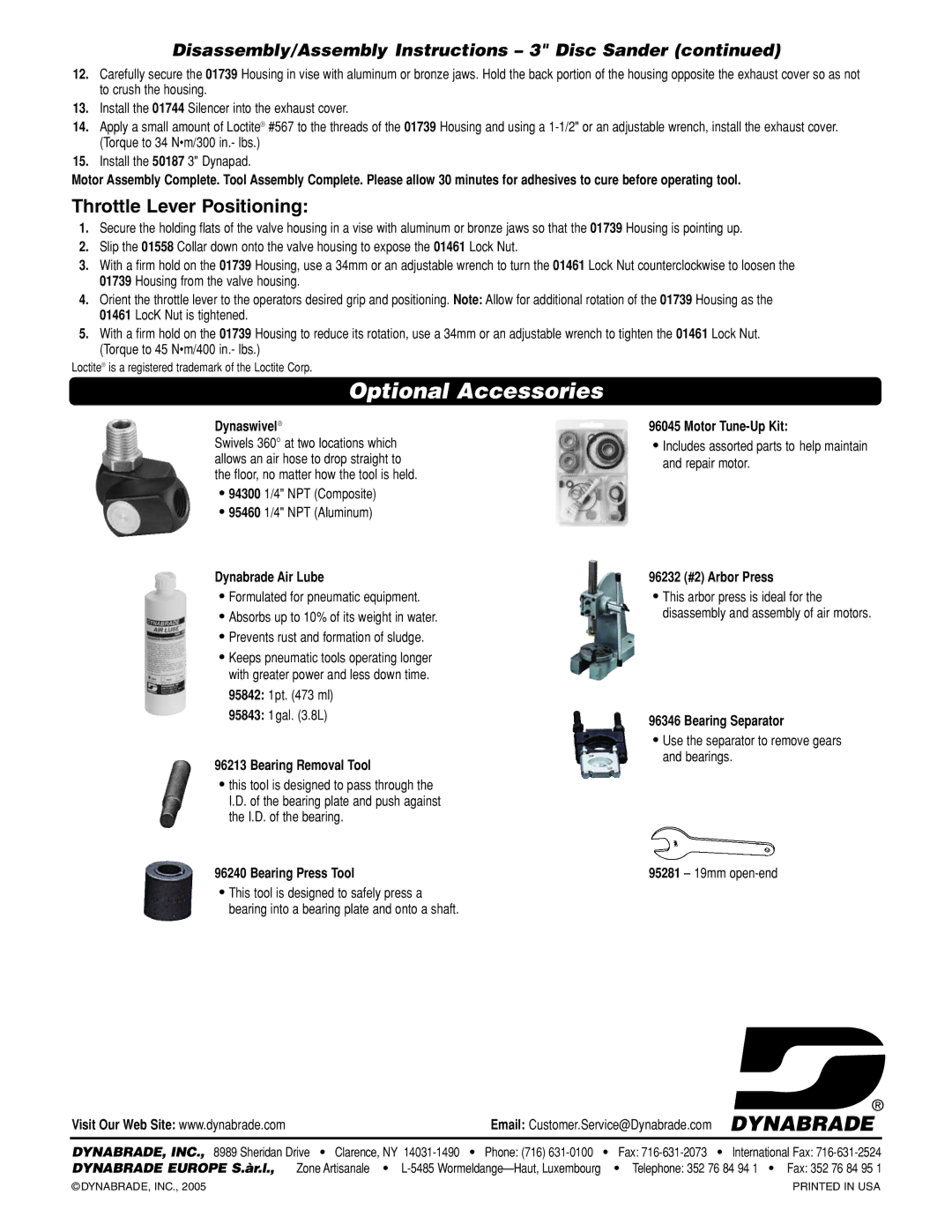

Optional Accessories

Dynaswivel®

Swivels 360° at two locations which allows an air hose to drop straight to the floor, no matter how the tool is held.

•94300 1/4" NPT (Composite)

•95460 1/4" NPT (Aluminum)

Dynabrade Air Lube

•Formulated for pneumatic equipment.

•Absorbs up to 10% of its weight in water.

•Prevents rust and formation of sludge.

•Keeps pneumatic tools operating longer with greater power and less down time. 95842: 1pt. (473 ml)

95843: 1gal. (3.8L)

96213 Bearing Removal Tool

•this tool is designed to pass through the I.D. of the bearing plate and push against the I.D. of the bearing.

96045 Motor

•Includes assorted parts to help maintain and repair motor.

96232 (#2) Arbor Press

•This arbor press is ideal for the disassembly and assembly of air motors.

96346 Bearing Separator

•Use the separator to remove gears and bearings.

96240 Bearing Press Tool | 95281 – 19mm |

•This tool is designed to safely press a bearing into a bearing plate and onto a shaft.

|

|

| ® |

Visit Our Web Site: www.dynabrade.com | Email: Customer.Service@Dynabrade.com | DYNABRADE | |

DYNABRADE, INC., 8989 Sheridan Drive • Clarence, NY | • Fax: | International Fax: | |

DYNABRADE EUROPE S.àr.l., | Zone Artisanale • | • Telephone: 352 76 84 94 1 • Fax: 352 76 84 95 1 | |

© DYNABRADE, INC., 2005 | PRINTED IN USA |