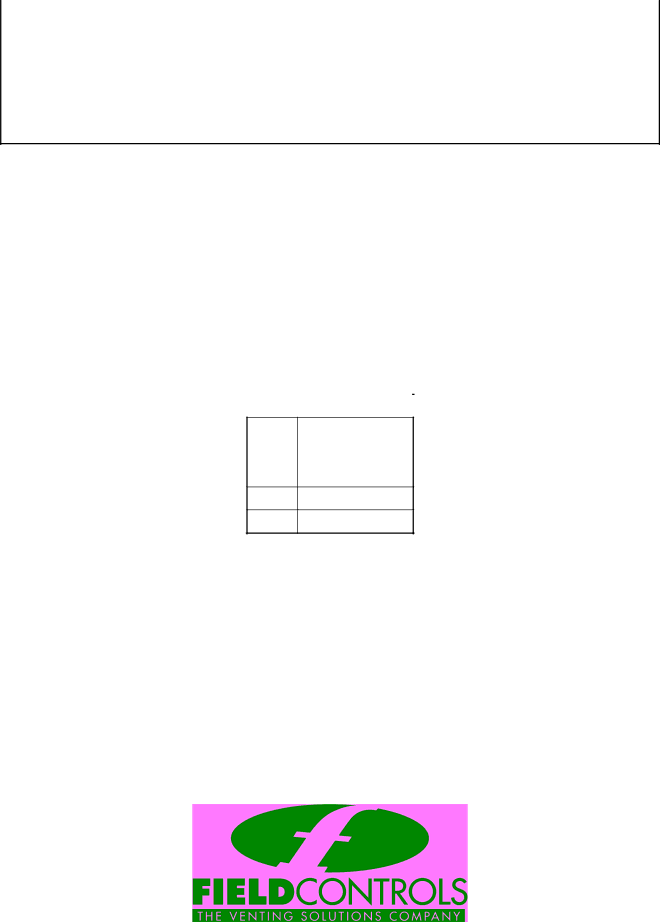

Longer pipe lengths require the use of a larger pipe between the VRV and the intake hood. It also requires the use of a vent pipe increaser at the VRV and a reducer at the intake hood. (See Table 1)

Table 1

Pipe |

| Maximum Equivalent |

|

| Elbow* |

|

| Reducer or |

|

| Pipe Feet (between Air boot™ |

|

| Equivalent |

|

| Increaser |

| |

Diameter |

|

|

|

|

|

| |||

| and duct termination) |

|

| Feet |

|

| Equivalent Feet |

| |

|

|

|

|

|

|

| |||

4” |

| 44’ |

|

| 7’ |

| - |

| |

|

|

|

|

|

|

|

|

|

|

5” |

| 60’ |

|

| 9’ |

|

| (4” to 5”) 3’ |

|

|

|

|

|

|

|

|

|

|

|

6” |

| 90’ |

|

| 11’ |

|

| (4” to 6”) 6’ |

|

|

|

|

|

|

|

|

|

|

|

*Note: Subtract the elbow or reducer equivalent feet from the maximum equivalent feet to get maximum linear feet of pipe

2.Route the duct work from the VRV tee to the inlet vent termination with as minimum a number of elbows as possible.

3.Secure and support the duct work for the design and weight of the material used, to prevent physical damage and separation of joints. For guidelines refer to recognized national building codes or according to any local codes.

4.To reduce uncontrolled air leakage into the duct, tape all joints and seams using standard duct tape.

NOTE: To prevent sweating on the outside of the duct, when operating in areas that have

AIR ADJUSTMENT

1. Adjust the air adjustment knob on the side of the Air Boot™ (See Table 2) to rough air setting.

Table 2

ROUGH AIR SETTING

GPH | Knob Setting |

|

|

.75 | 70° |

1.0090°

1.50135°

2.Start the burner and adjust the air control as needed to achieve the required CO2 and smoke levels. Set over fire draft to appliance manufacturers’ specifications (typically

3.Next, adjust the VRV gate by screwing the adjustment weight in until the VRV gate is just closed.

4.

5.Lock the adjustment weight in position by tightening the hex nut on the VRV gate.

Page 4 | PN 46385600 6/00 |

|