PerformanceDataSheet

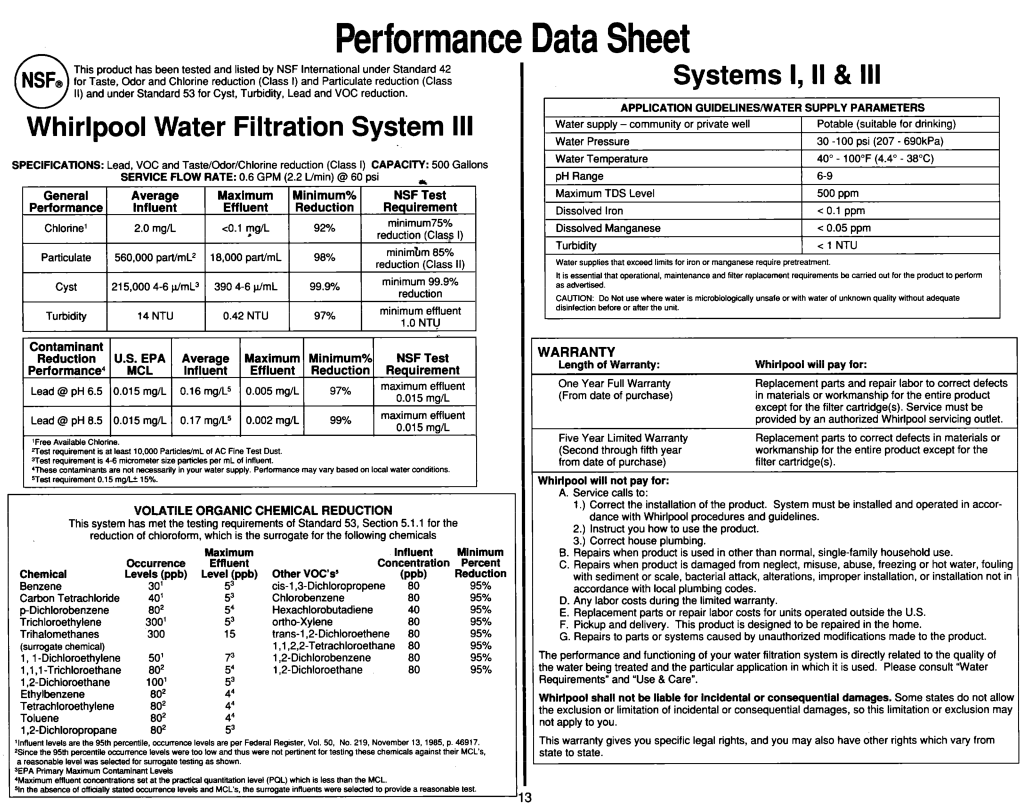

This product has been tested and listed by NSF International under Standard 42 for Taste, Odor and Chlorine reduction (Class I) and Particulate reduction (Class II) and under Standard 53 for Cyst, Turbidity, Lead and VOC reduction.

Whirlpool Water Filtration System Ill

SPECIFICATIONS: Lead, VOC and Taste/Odor/Chlorine reduction (Class I) CAPACITY: 500 Gallons

SERVICE FLOW RATE: 0.6 GPM (2.2 Umin) @ 60 psi

General | Average | Maximum | Minimum% | NSF Test |

| ||||

Performance | lnfluent | Effluent | Reduction | Requirement |

| ||||

Chlorine1 | 2.0 | mg/L | co.1 | ?glL | 92% | minimum75% |

| ||

reduction | IClass | I) | |||||||

|

|

|

|

|

| ||||

Particulate | 560,000 | part/ml2 | 18,000 | parVmL | 98% | minimbm 85% |

| ||

reduction | (Class | II) | |||||||

|

|

|

|

|

| ||||

cyst | 215,000 | 390 | 99.9% | minimum | 99.9% |

| |||

|

|

|

|

|

| reduction |

| ||

Turbidity | 14 NTU | 0.42 | NTU | 97% | minimum | effluent |

| ||

1.O NTU |

| ||||||||

|

|

|

|

|

|

| |||

|

|

| Systems | I, II & Ill |

| ||

|

| APPLICATION GUIDELINESMATER SUPPLY PARAMETERS | |||||

Water | SUDDIV - | community or orivate well |

| Potable (suitable | for drinking) | ||

Water | Pressure |

|

| 30 | |||

Water | Temperature |

| 40” - 100°F (4.4” | - 38°C) | |||

OH Ranoe |

|

| 1 |

|

| ||

Maximum | TDS | Level | I | 500 ppm |

| ||

I Dissolved | Iron |

| I | c 0.1 | ppm |

| |

Dissolved | Manganese |

| < 0.05 | ppm |

| ||

Turbidity |

|

|

| < 1 NTU |

| ||

Waier supplies that exceed limits for iron or manganese require pretreatment.

It is essential that operalional, maintenance and filter replacement requirements be carried out for Ihe product to perform as advertised.

CAUTION: Do Not use where water is microbiologically unsaie or with waler of unknown quality withour adequate disinlection before or after the umt.

I

I I

Contaminant | U.itfA |

| Average | Maximum | Minimum% | NSF Test | |||||

Reduction |

| ||||||||||

Performance4 |

|

| lnfluent | Effluent | Reduction | Requirement | |||||

Lead | @ pH 6.5 | 0.015 | mg/L | 0.16 | mg/L5 | 0.005 | mg/L | 97% | maximum | effluent | |

0.015 | ma/L | ||||||||||

|

| I |

|

|

| I |

|

| |||

Lead | @ pH 8.5 | 0.015 | mg/L | 0.17 | mg/L5 | 0.002 | mg/L | 99% | maximum | effluent | |

0.015 | mg/L | ||||||||||

|

|

|

|

|

|

|

|

| |||

‘Free Available Chlorine.

Test requirement is at leas.1 10,000 ParticletimL of AC Fine Test Dust. 3Tes.l reouirement is

WARRANTY

Length of Warranty:

One Year Full Warranty (From date of purchase)

Five Year Limited Warranty (Second through fifth year from date of purchase)

Whirlpool will pay for:

Replacement parts and repair labor to correct defects in materials or workmanship for the entire product except for the filter cartridge(s). Service must be provided by an authorized Whirlpool servicing outlet.

Replacement parts to correct defects in materials or workmanship for the entire product except for the filter cartridge(s).

‘These &taminants are not necessarily in your w&r supply. Perlormance may vary based on local water conditions. 5Test requirement 0.15 rn@ 15%.

VOLATILE ORGANIC CHEMICAL REDUCTION

This system has met the testing requirements of Standard 53, Section 5.1.1 for the reduction of chloroform, which is the surrogate for the following chemicals

Whlrlpool will not pay for:

A. Service calls to:

1.) Correct the installation of the product. System must be installed and operated in accor- dance with Whirlpool procedures and guidelines.

2.) Instruct you how to use the product.

3.) Correct house plumbing.

|

| Maximum | |

Chemical | Occurrence | Effluent | |

Levels (ppb) | Level (ppb) | ||

Benzene | 30’ | ;: | |

Carbon Tetrachtortde | 40’ | ||

| |||

80’ | $ | ||

Trichloroethylene | 300’ | ||

| |||

Trihalomethanes | 300 | 15 | |

(surrogate chemical) |

|

| |

1, | 50’ | g: | |

1,l ,l | 80’ | ||

| |||

100’ | 2: | ||

Ethylbenzene | 802 | ||

| |||

Tetrachloroethylene | 802 | ;: | |

Toluene | 802 | ||

| |||

80’ | 53 |

| lnfluent | Mlnimum |

| Concentration | Percent |

Other VOc’s’ | ‘PBpob’ | Reduction |

| 95% | |

Chlorobenzene | 80 | 95% |

Hexachlorobutadiene | 40 | 95% |

80 | 95% | |

80 | 95% | |

80 | 95% | |

80 | 95% | |

80 | 95% |

B. Repairs when product is used in other than normal,

C. Repairs when product is damaged from neglect, misuse, abuse, freezing or hot water, fouling with sediment or scale, bacterial attack, alterations, improper installation, or installation not in accordance with local plumbing codes.

D. Any labor costs during the limited warranty.

E. Replacement parts or repair labor costs for units operated outside the U.S. F. Pickup and delivery. This product is designed to be repaired in the home.

G. Repairs to parts or systems caused by unauthorized modifications made to the product.

The performance and functioning of your water filtration system is directly related to the quality of the water being treated and the particular application in which it is used. Please consult “Water Requirements” and “Use8 Care”.

Whirlpool shall not be Ilable for lncldental or consequential damages. Some states do not allow the exclusion or limitation of incidental or consequential damages, so this limitation or exclusion may not apply to you.

‘Influent levels are the 95th percentile, occu~ence levels are per Federal Reg~sler, Vol. 50, No. 219. November 13, 1965. p. 46917.

‘Since the s5mpercentile ooxnence levels were too low and thus were not pertinent for testing lhess chemicals against their MCL’s. a reasomble level was selected for surrogate tasting as shown.

‘EPA Primary Maximum Contaminant Levels

‘Maximum eflluem concentrations set at the practical quantitation level (PQL) which is less than the MCL.

9n the absence oi offiially stated occurrence levels and MCCs. tne surrogate mfluents were selected to provlaea reasonaole IesI.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.