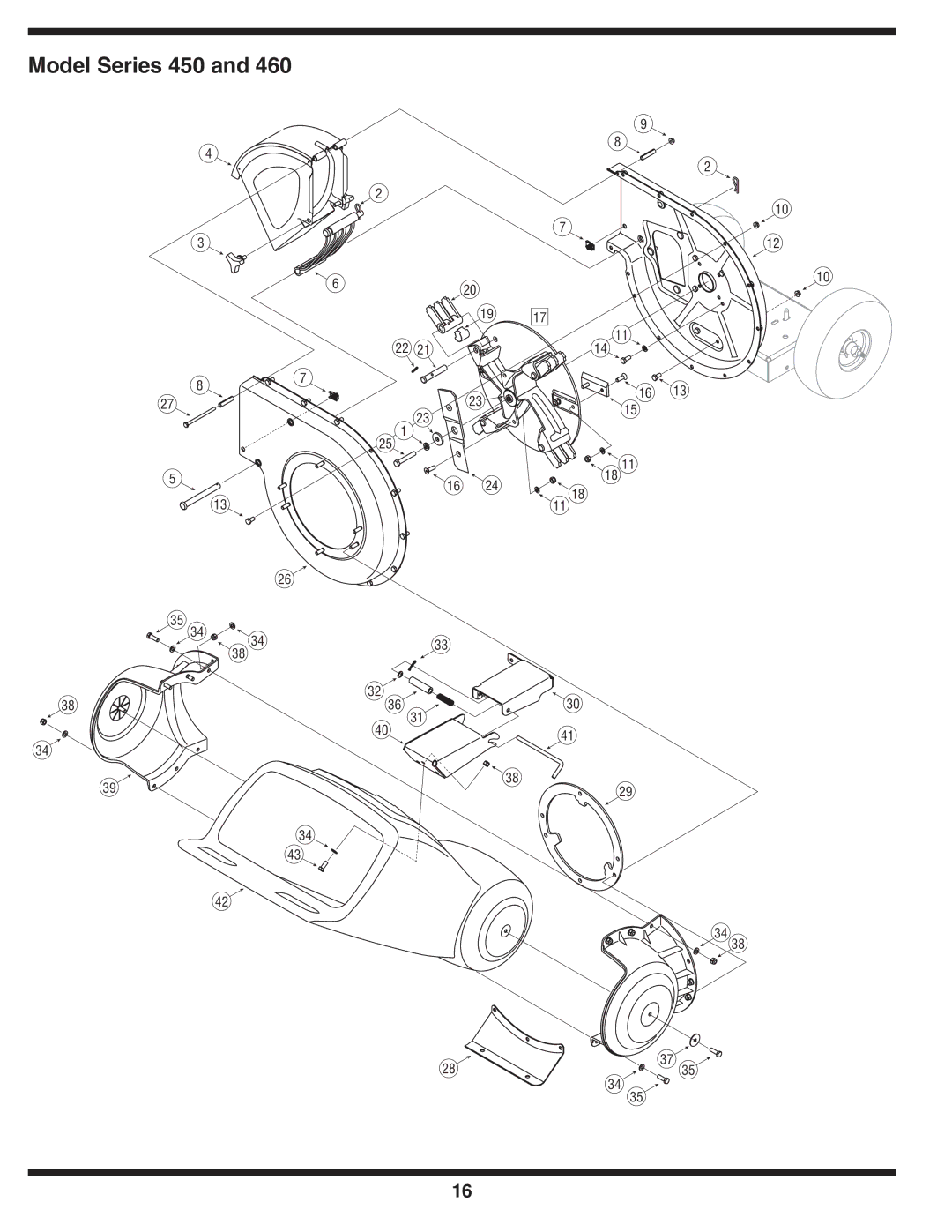

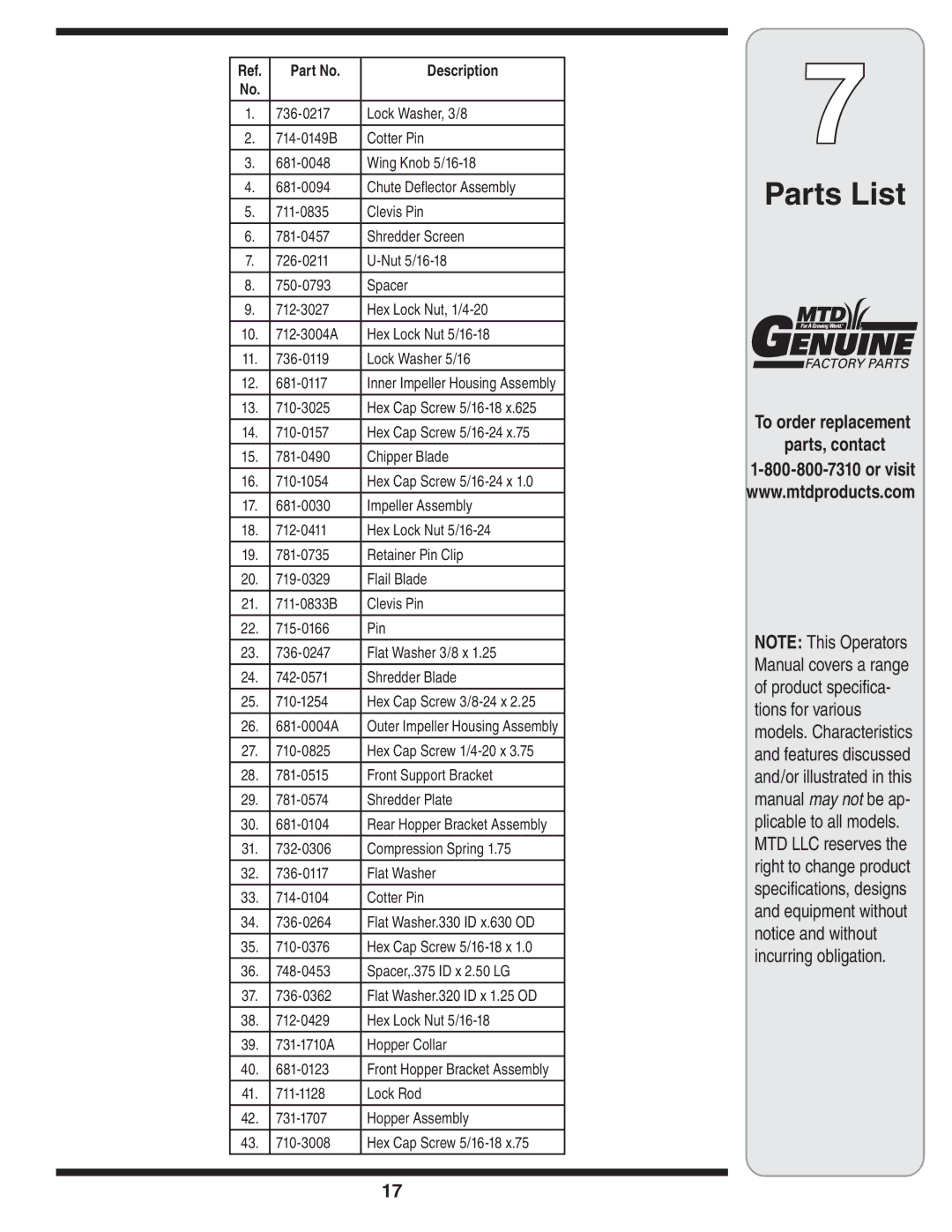

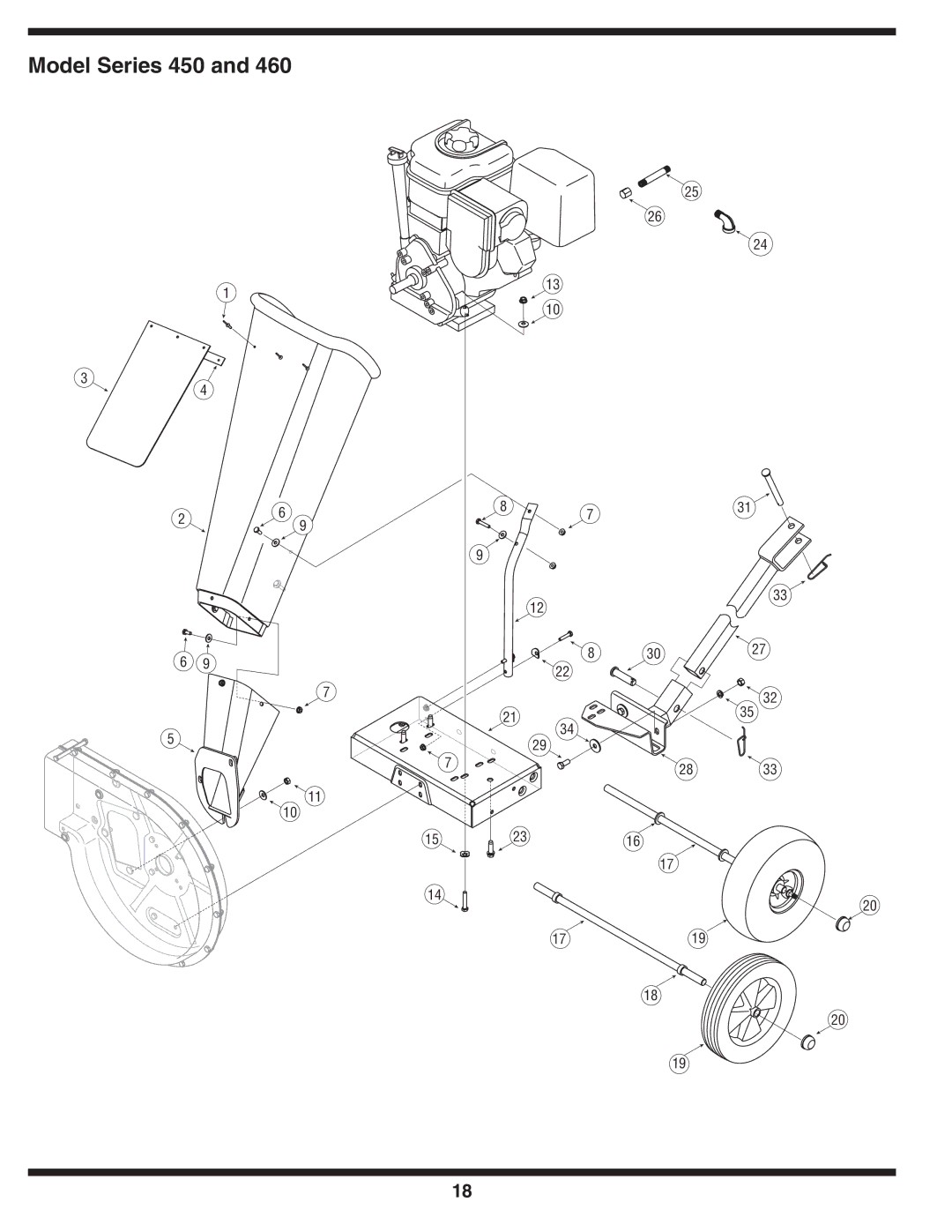

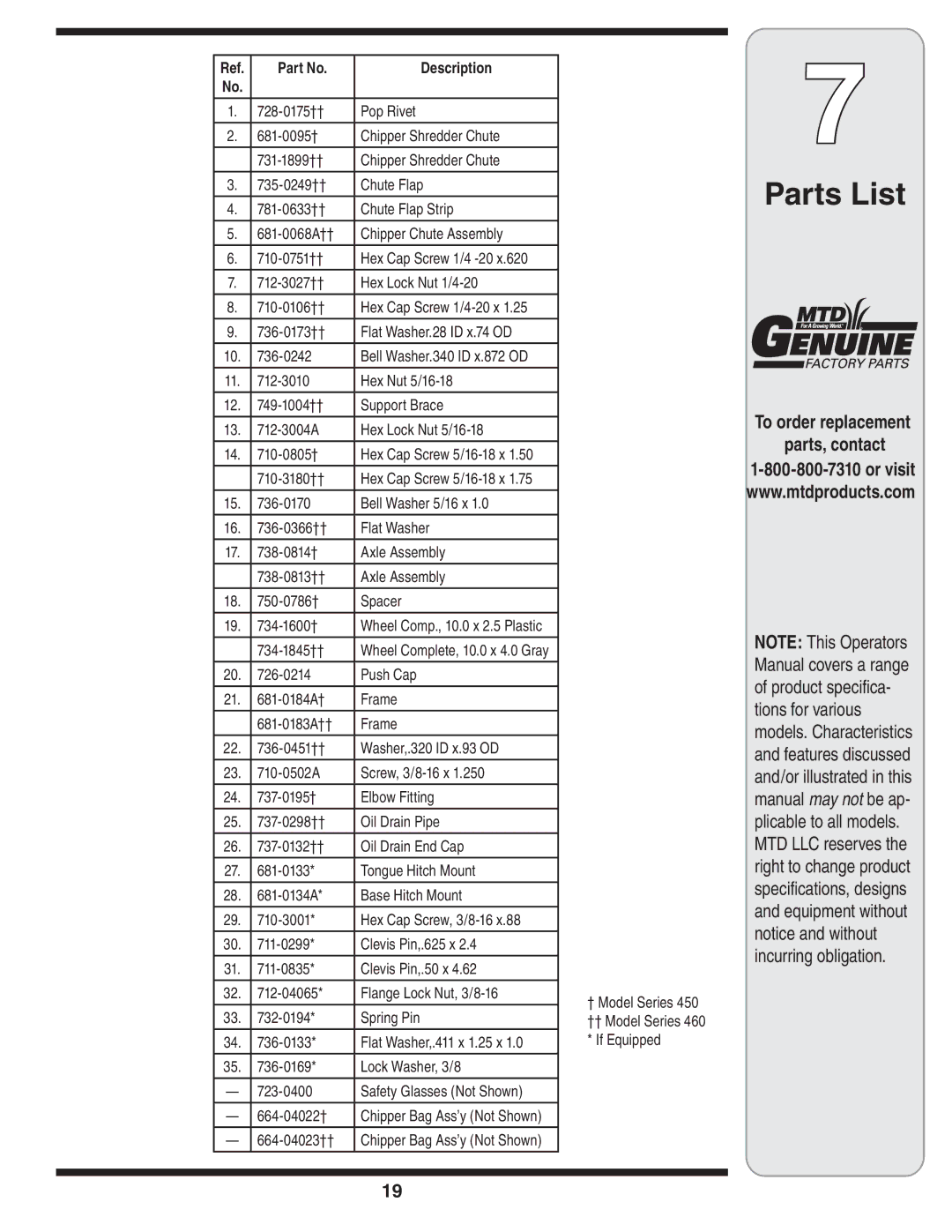

450 Series, 460 Series specifications

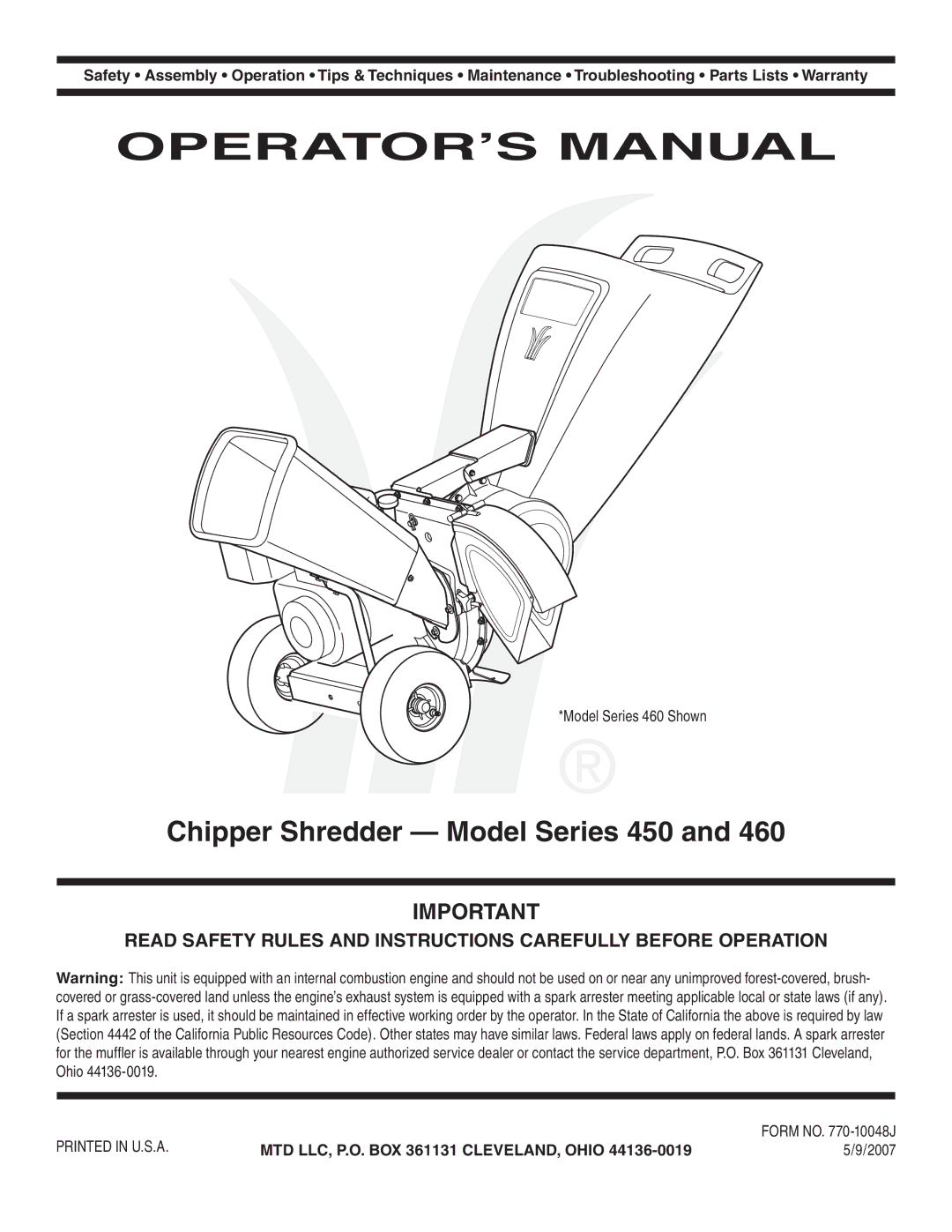

The Bolens 460 and 450 Series tractors represent a blend of robust engineering and user-friendly design, tailored to meet the needs of both commercial and residential users. Built with efficiency and versatility in mind, these tractors stand out in the competitive landscape of lawn and garden care equipment.One of the defining features of the Bolens 460 Series is its powerful engine. Equipped with a reliable and performance-oriented engine, this series is designed to tackle tough mowing conditions and heavy-duty landscaping tasks with ease. The engine not only delivers significant horsepower but also emphasizes fuel efficiency, ensuring that users can work longer without frequent refueling.

In contrast, the Bolens 450 Series is slightly more compact, making it ideal for residential settings and smaller properties. It combines power with agility, featuring a maneuverable design that allows for easy navigation around tight spaces and obstacles. The 450 Series is well-suited for homeowners seeking to maintain their lawns and gardens without the bulk of larger equipment.

Both series are equipped with hydrostatic transmissions, providing seamless speed control and eliminating the need for manual gear shifting. This technology enhances user comfort and allows for a more enjoyable mowing experience, especially on uneven terrain. Additionally, the ergonomic seating and controls ensure that operators can work for extended periods without fatigue.

A standout characteristic of the Bolens 460 and 450 Series is their cutting systems. Both series feature innovative mowing decks designed to deliver a clean and precise cut every time. With adjustable cutting heights, users can easily customize their mowing experience to achieve the desired lawn finish. Furthermore, the optional mulch kit enhances the effectiveness of grass clippings, returning valuable nutrients to the soil.

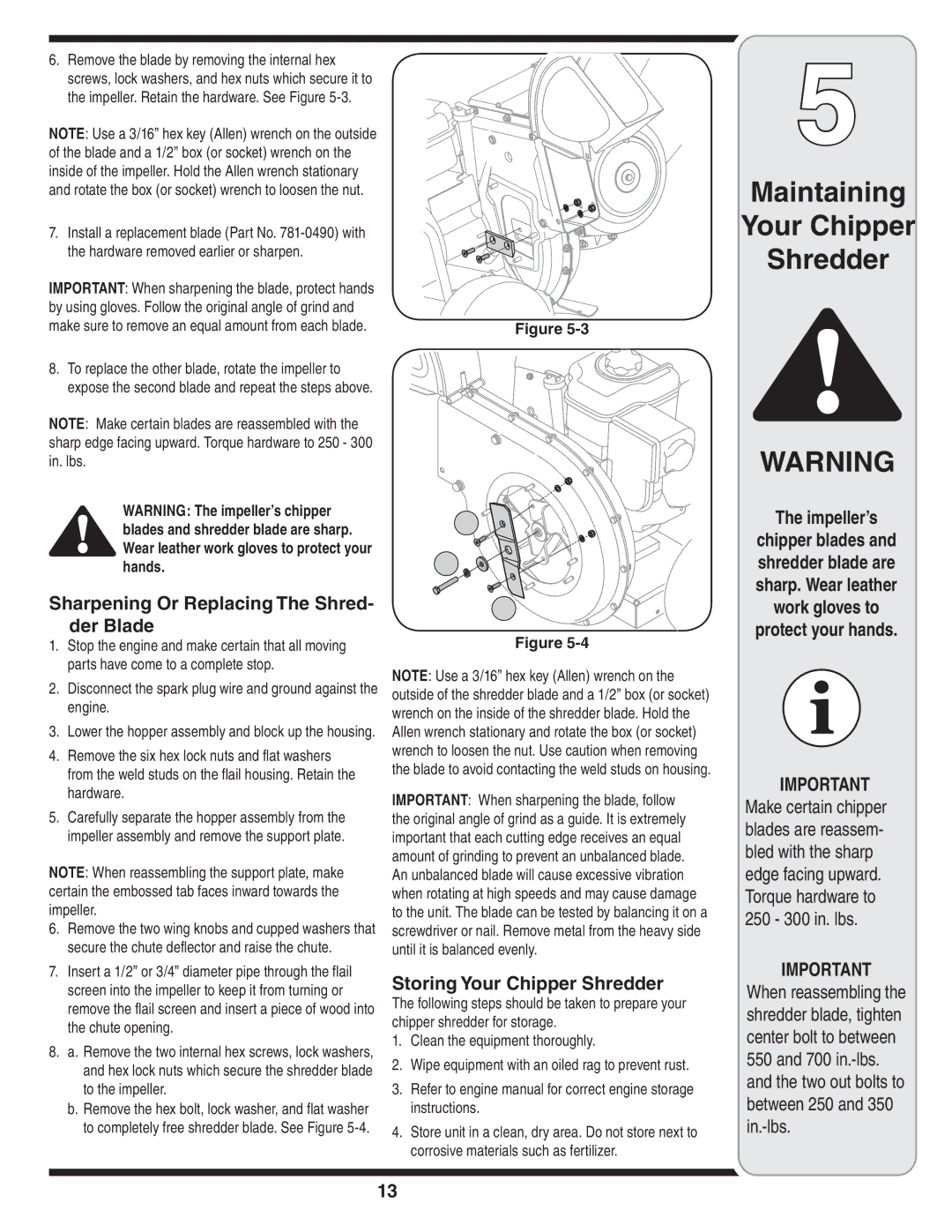

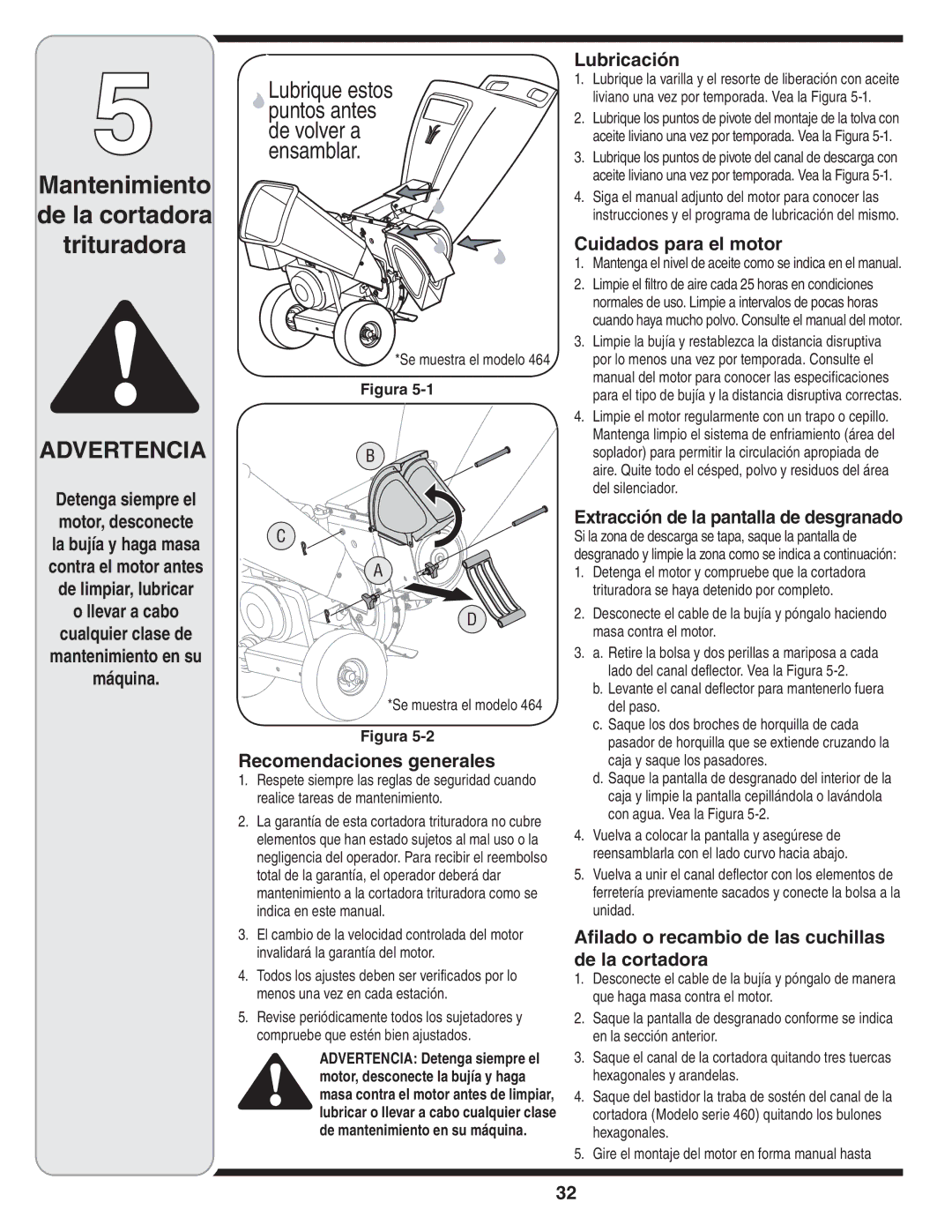

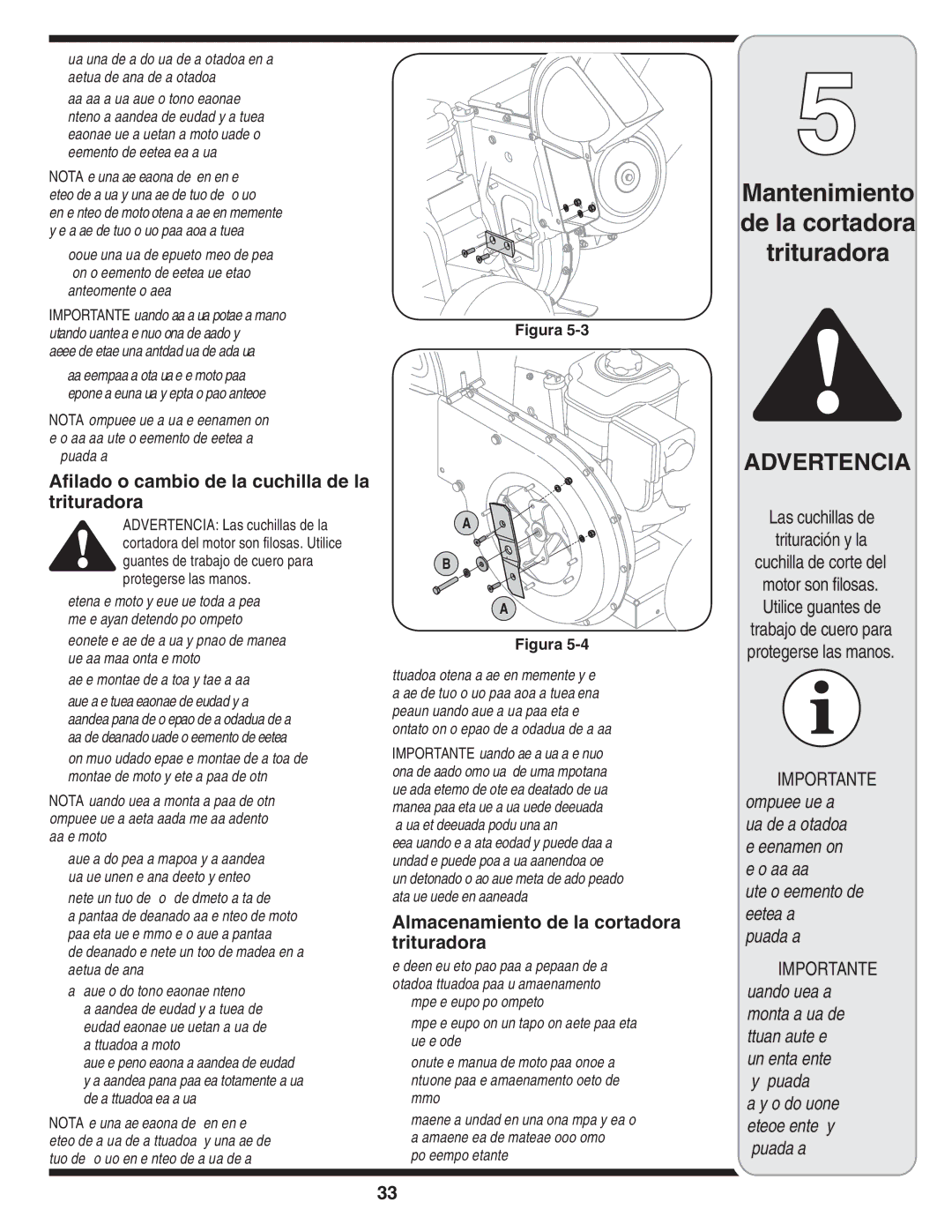

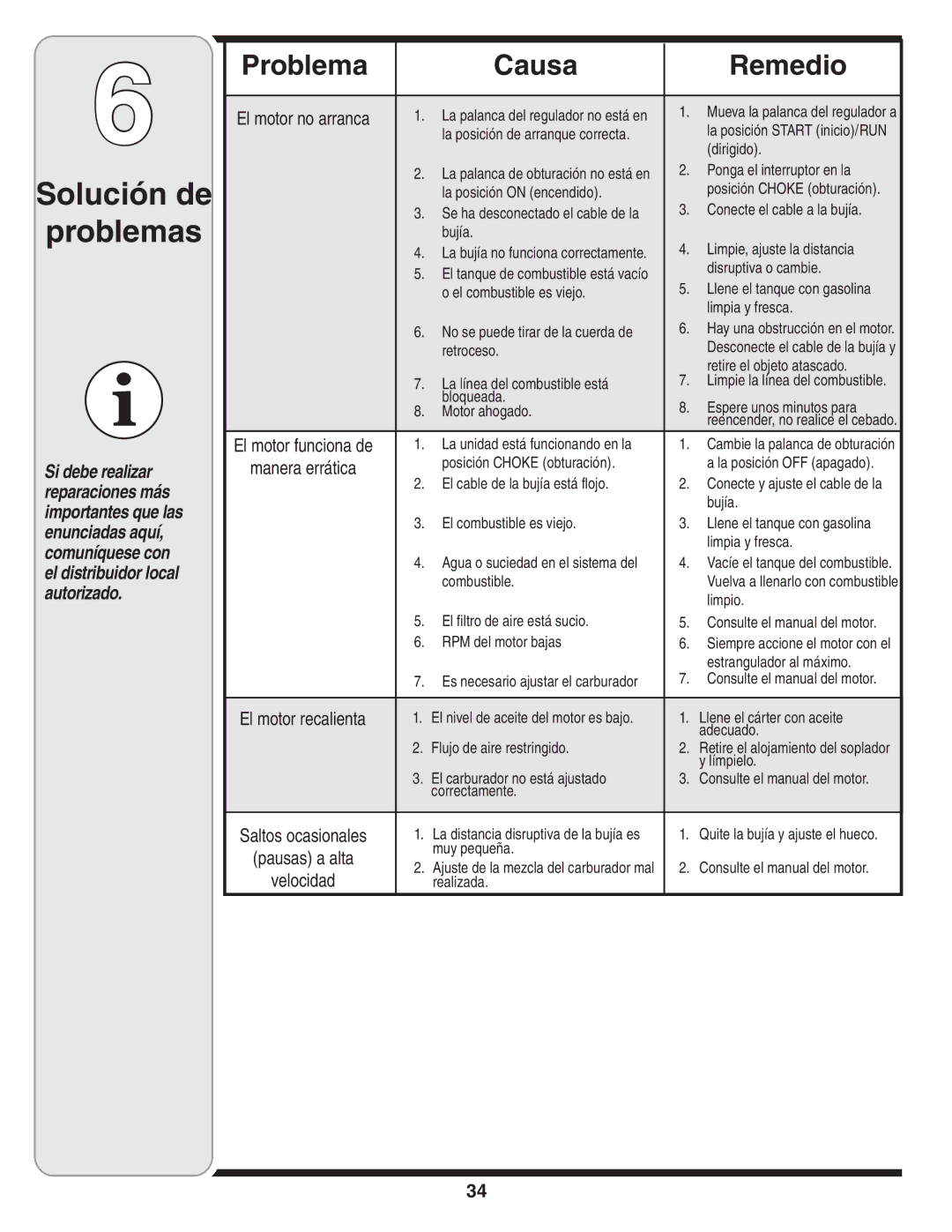

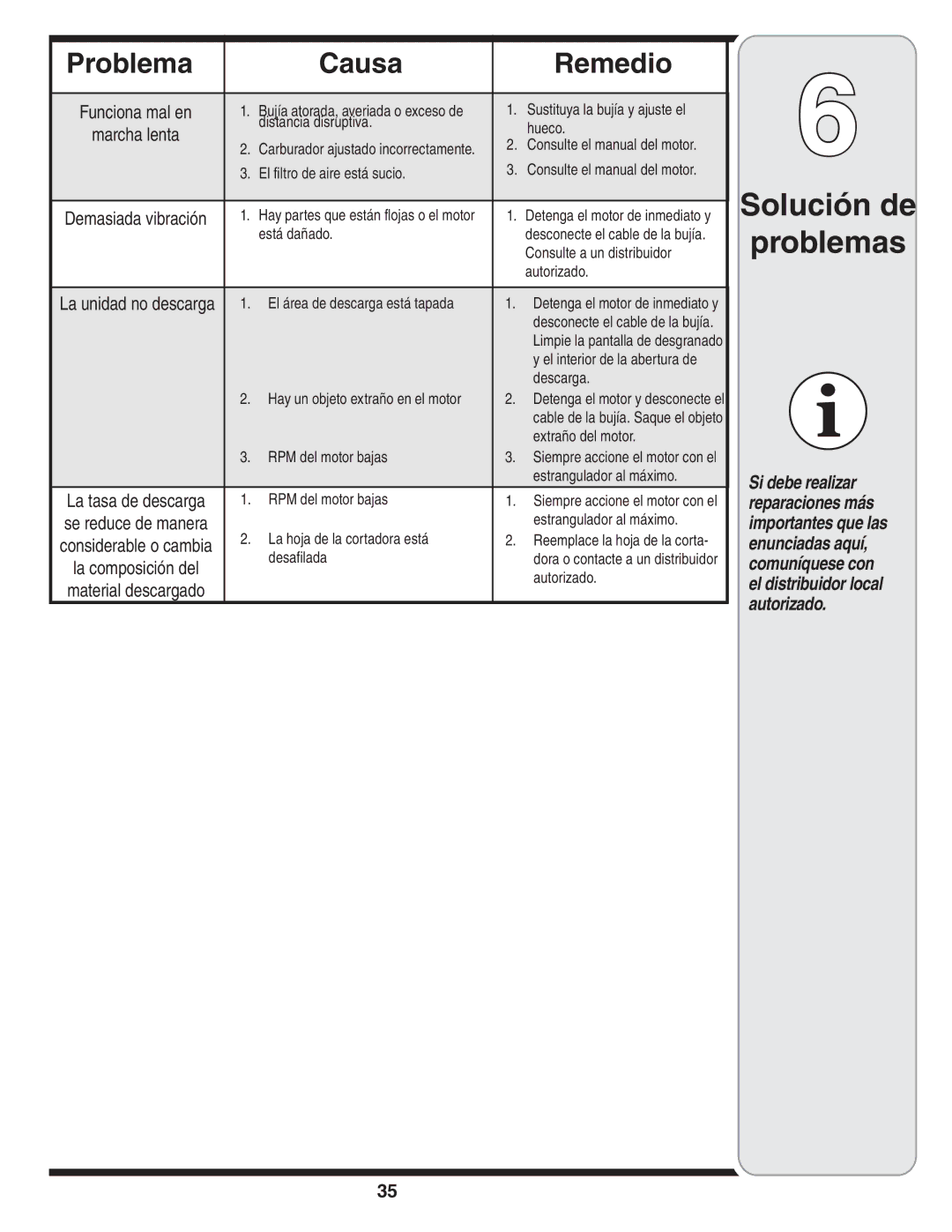

Maintenance is made straightforward with these tractors, as both the 460 and 450 Series come with accessible components for easy servicing. This user-centric design philosophy ensures that owners can keep their equipment in top-notch condition without the hassle often associated with complex machinery.

In summary, the Bolens 460 and 450 Series tractors offer a perfect combination of power, efficiency, and user-friendly features. With their innovative technologies and thoughtful design characteristics, they serve as reliable companions for all lawn and garden care tasks, guaranteeing satisfaction for both commercial operators and homeowners alike. Whether you are looking to tackle large properties or maintain a smaller yard, these series provide diverse solutions for your outdoor needs.