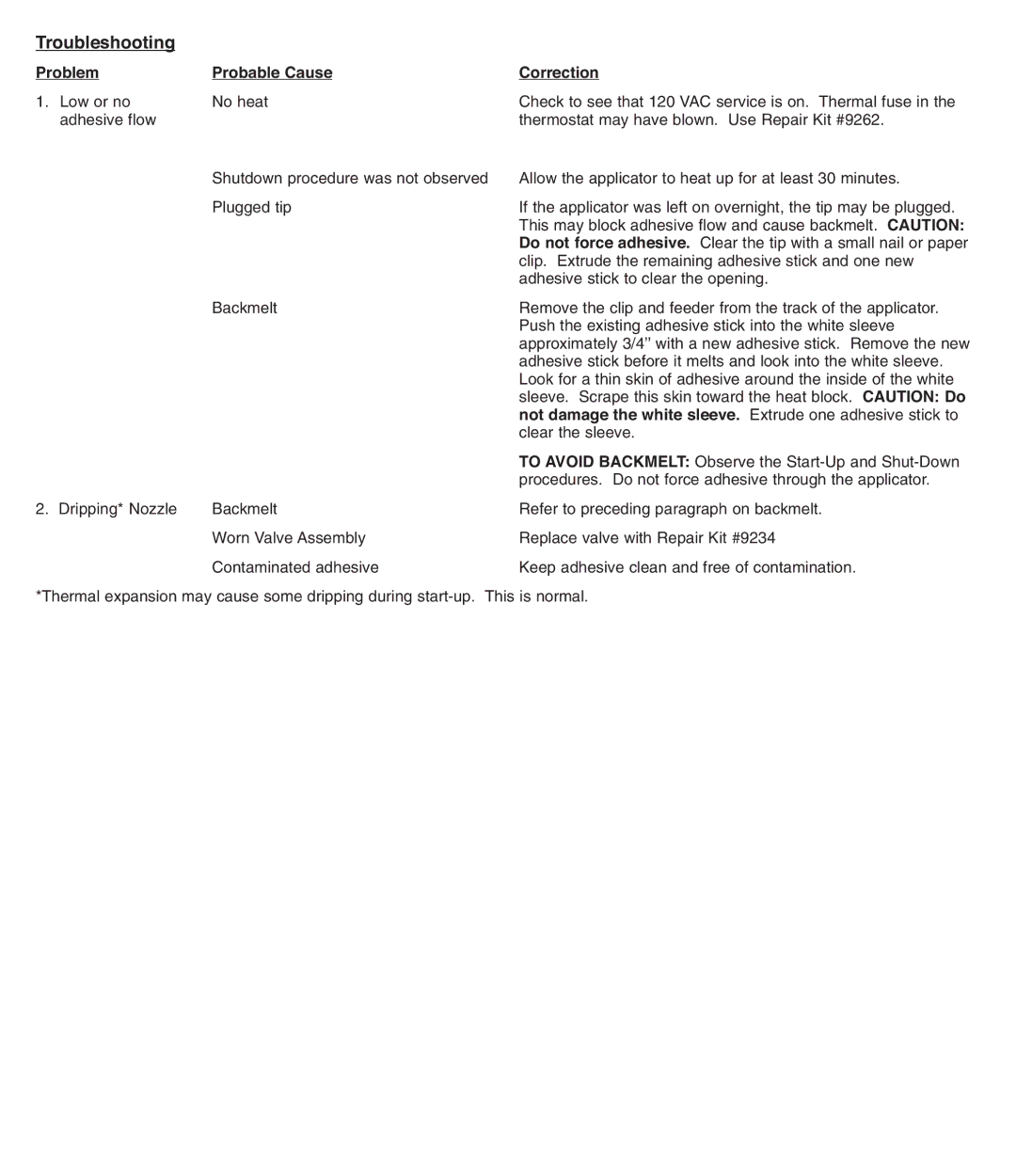

Troubleshooting

Problem | Probable Cause | Correction | |

1. | Low or no | No heat | Check to see that 120 VAC service is on. Thermal fuse in the |

| adhesive flow |

| thermostat may have blown. Use Repair Kit #9262. |

|

| Shutdown procedure was not observed | Allow the applicator to heat up for at least 30 minutes. |

|

| Plugged tip | If the applicator was left on overnight, the tip may be plugged. |

|

|

| This may block adhesive flow and cause backmelt. CAUTION: |

|

|

| Do not force adhesive. Clear the tip with a small nail or paper |

|

|

| clip. Extrude the remaining adhesive stick and one new |

|

|

| adhesive stick to clear the opening. |

|

| Backmelt | Remove the clip and feeder from the track of the applicator. |

|

|

| Push the existing adhesive stick into the white sleeve |

|

|

| approximately 3/4’’ with a new adhesive stick. Remove the new |

|

|

| adhesive stick before it melts and look into the white sleeve. |

|

|

| Look for a thin skin of adhesive around the inside of the white |

|

|

| sleeve. Scrape this skin toward the heat block. CAUTION: Do |

|

|

| not damage the white sleeve. Extrude one adhesive stick to |

|

|

| clear the sleeve. |

|

|

| TO AVOID BACKMELT: Observe the |

|

|

| procedures. Do not force adhesive through the applicator. |

2. | Dripping* Nozzle | Backmelt | Refer to preceding paragraph on backmelt. |

|

| Worn Valve Assembly | Replace valve with Repair Kit #9234 |

|

| Contaminated adhesive | Keep adhesive clean and free of contamination. |

*Thermal expansion may cause some dripping during