Hot Water Outlet

Metal Drain

Pan

Depth Max.

In a closed system use a thermal expansion tank

Cold Water

Inlet Valve

Cold Water Supply![]() to Fixture

to Fixture

Temperature and Pressure (T&P)

![]() Relief Valve (Optional Top T&P

Relief Valve (Optional Top T&P

Relief Valve Not Shown)

Massachusetts: Install a vacuum relief in cold water line per section 19 MGL 142

Discharge line

(Do Not Cap or Plug)

1“ Min.

Drain line 3/4” | |

ID Min. |

|

Drain | 6“ Min. |

Closed System/Thermal Expansion

As water is heated, it expands (thermal expansion). In a closed system, the volume of water will grow. As the volume of water grows, there will be a corresponding increase in water pressure due to thermal expansion. Thermal expansion can cause premature tank failure (leakage). This type of failure is not covered under the limited warranty. Thermal expansion can also cause intermittent

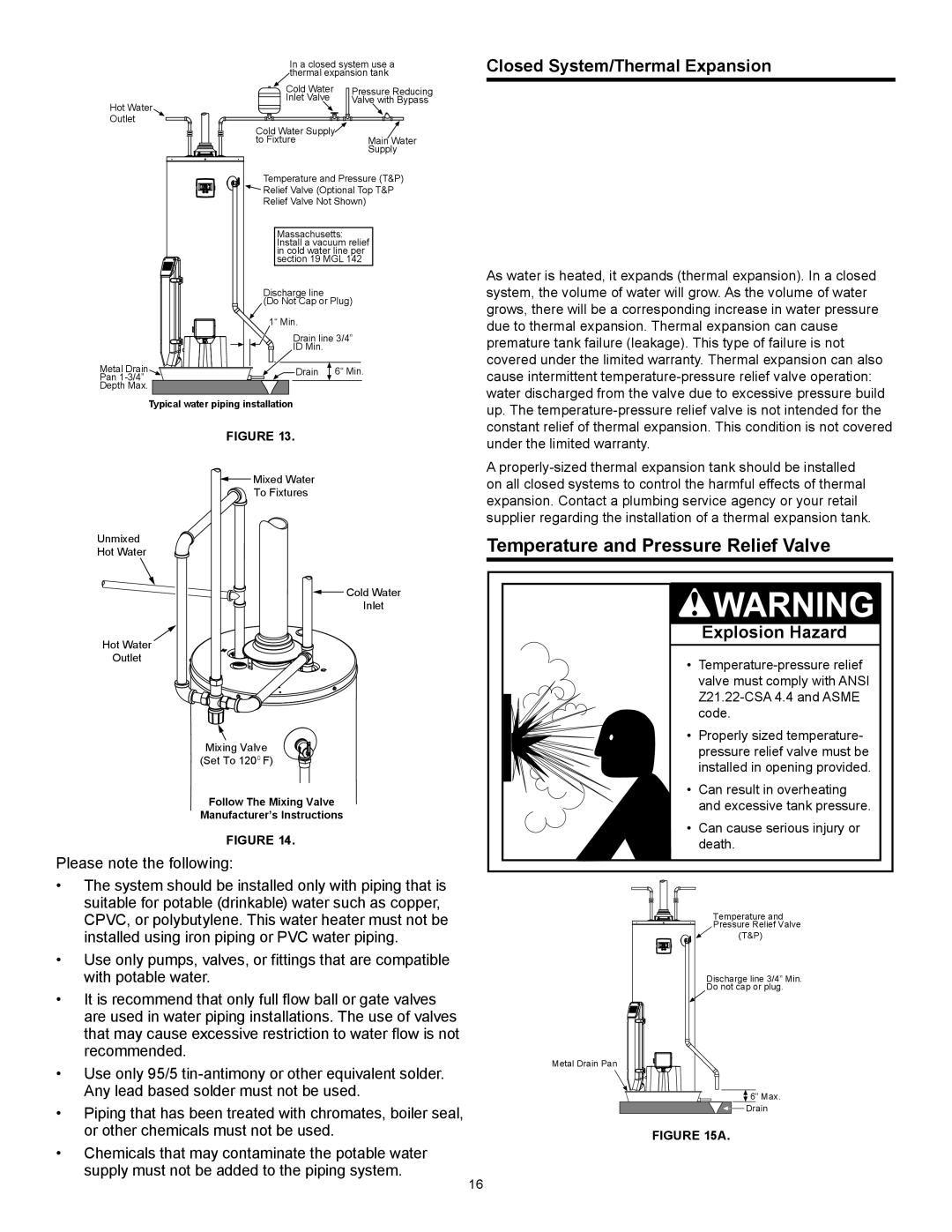

Typical water piping installation

FIGURE 13.

![]() Mixed Water

Mixed Water

To Fixtures

Unmixed

Hot Water

![]() Cold Water

Cold Water

Inlet

Hot Water

Outlet

Mixing Valve

(Set To 1200 F)

Follow The Mixing Valve

Manufacturer’s Instructions

FIGURE 14.

Please note the following:

•The system should be installed only with piping that is suitable for potable (drinkable) water such as copper, CPVC, or polybutylene. This water heater must not be installed using iron piping or PVC water piping.

•Use only pumps, valves, or fittings that are compatible with potable water.

•It is recommend that only full flow ball or gate valves are used in water piping installations. The use of valves that may cause excessive restriction to water flow is not recommended.

•Use only 95/5

•Piping that has been treated with chromates, boiler seal, or other chemicals must not be used.

•Chemicals that may contaminate the potable water supply must not be added to the piping system.

up. The

A

Temperature and Pressure Relief Valve

Explosion Hazard

•

• Properly sized temperature- pressure relief valve must be installed in opening provided.

• Can result in overheating and excessive tank pressure.

• Can cause serious injury or death.

Temperature and

Pressure Relief Valve

(T&P)

Discharge line 3/4” Min.

Do not cap or plug.

Metal Drain Pan

![]() 6” Max.

6” Max.

![]() Drain

Drain

FIGURE 15A.

16