cont.

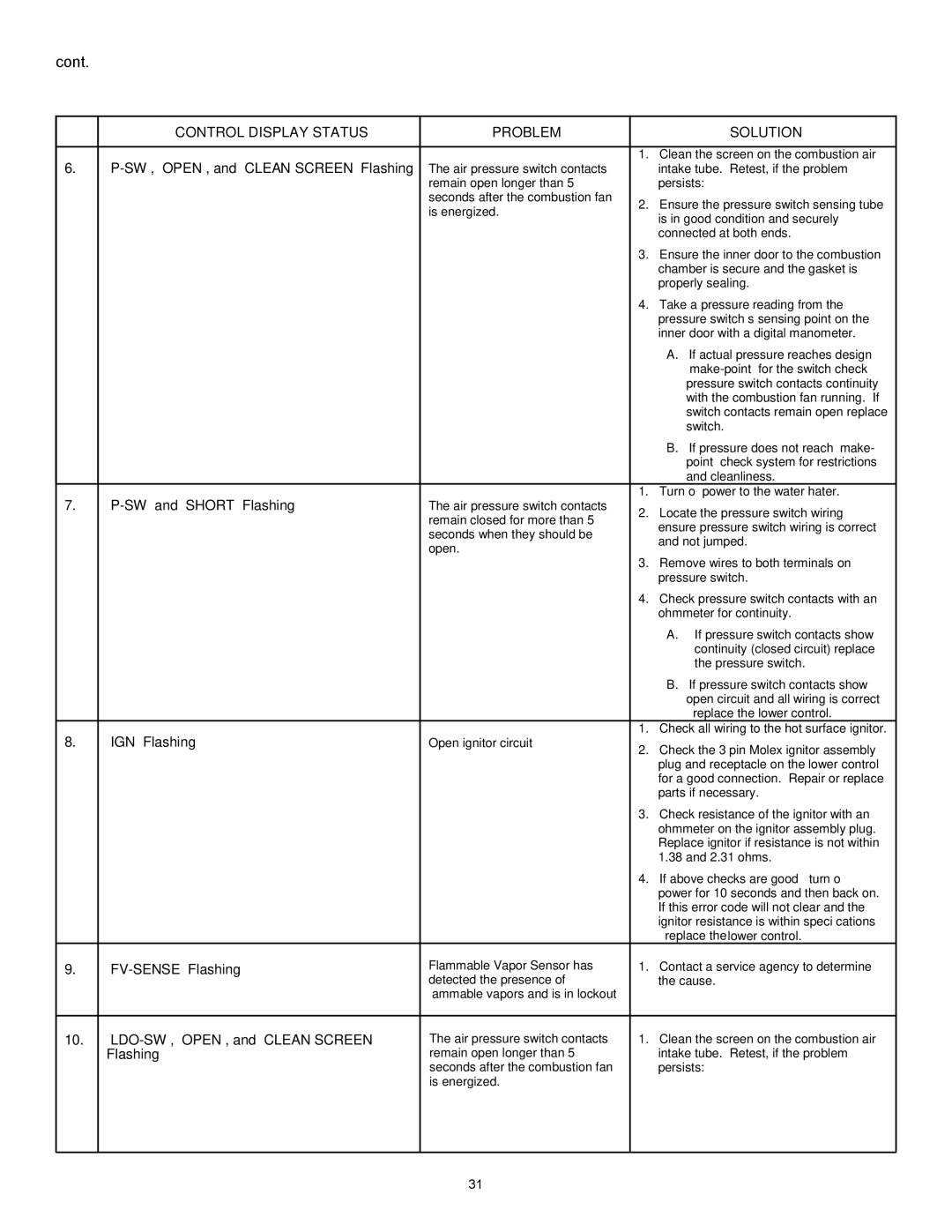

| CONTROL DISPLAY STATUS | PROBLEM |

| SOLUTION | |

|

|

|

|

| |

6. |

|

| 1. | Clean the screen on the combustion air | |

The air pressure switch contacts |

| intake tube. Retest, if the problem | |||

|

| remain open longer than 5 |

| persists: | |

|

| seconds after the combustion fan | 2. | Ensure the pressure switch sensing tube | |

|

| is energized. | |||

|

|

| is in good condition and securely | ||

|

|

|

| ||

|

|

|

| connected at both ends. | |

|

|

| 3. | Ensure the inner door to the combustion | |

|

|

|

| chamber is secure and the gasket is | |

|

|

|

| properly sealing. | |

|

|

| 4. | Take a pressure reading from the | |

|

|

|

| pressure switch’s sensing point on the | |

|

|

|

| inner door with a digital manometer. | |

|

|

|

| A. If actual pressure reaches design | |

|

|

|

| ||

|

|

|

| pressure switch contacts continuity | |

|

|

|

| with the combustion fan running. If | |

|

|

|

| switch contacts remain open replace | |

|

|

|

| switch. | |

|

|

|

| B. If pressure does not reach “make- | |

|

|

|

| point” check system for restrictions | |

|

|

|

| and cleanliness. | |

7. |

| The air pressure switch contacts | 1. | Turn off power to the water hater. | |

2. | Locate the pressure switch wiring – | ||||

|

| remain closed for more than 5 | |||

|

|

| ensure pressure switch wiring is correct | ||

|

| seconds when they should be |

| ||

|

|

| and not jumped. | ||

|

| open. |

| ||

|

| 3. | Remove wires to both terminals on | ||

|

|

| |||

|

|

|

| pressure switch. | |

|

|

| 4. | Check pressure switch contacts with an | |

|

|

|

| ohmmeter for continuity. | |

|

|

|

| A. If pressure switch contacts show | |

|

|

|

| continuity (closed circuit) replace | |

|

|

|

| the pressure switch. | |

|

|

|

| B. If pressure switch contacts show | |

|

|

|

| open circuit and all wiring is correct | |

|

|

|

| – replace the lower control. | |

8. | “IGN” Flashing | Open ignitor circuit | 1. | Check all wiring to the hot surface ignitor. | |

2. | Check the 3 pin Molex ignitor assembly | ||||

|

|

| |||

|

|

|

| plug and receptacle on the lower control | |

|

|

|

| for a good connection. Repair or replace | |

|

|

|

| parts if necessary. | |

|

|

| 3. | Check resistance of the ignitor with an | |

|

|

|

| ohmmeter on the ignitor assembly plug. | |

|

|

|

| Replace ignitor if resistance is not within | |

|

|

|

| 1.38 and 2.31 ohms. | |

|

|

| 4. | If above checks are good – turn off | |

|

|

|

| power for 10 seconds and then back on. | |

|

|

|

| If this error code will not clear and the | |

|

|

|

| ignitor resistance is within specifications | |

|

|

|

| – replace the lower control. | |

9. |

| Flammable Vapor Sensor has | 1. | Contact a service agency to determine | |

|

| detected the presence of |

| the cause. | |

|

| flammable vapors and is in lockout |

|

| |

|

|

|

|

| |

10. | The air pressure switch contacts | 1. | Clean the screen on the combustion air | ||

| Flashing | remain open longer than 5 |

| intake tube. Retest, if the problem | |

|

| seconds after the combustion fan |

| persists: | |

|

| is energized. |

|

| |

|

|

|

|

|

31